Flexible flat cable and thin film transistor liquid crystal display panel drive structure

A flexible flat cable and drive structure technology, applied in circuits, electrical components, nonlinear optics, etc., can solve problems such as short circuit of adjacent Pins, PCB burning, etc., to prevent left and right displacement, prevent insertion skew, and reduce PCB burning. effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the flexible flat cable and the driving structure of the thin film transistor liquid crystal display panel provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

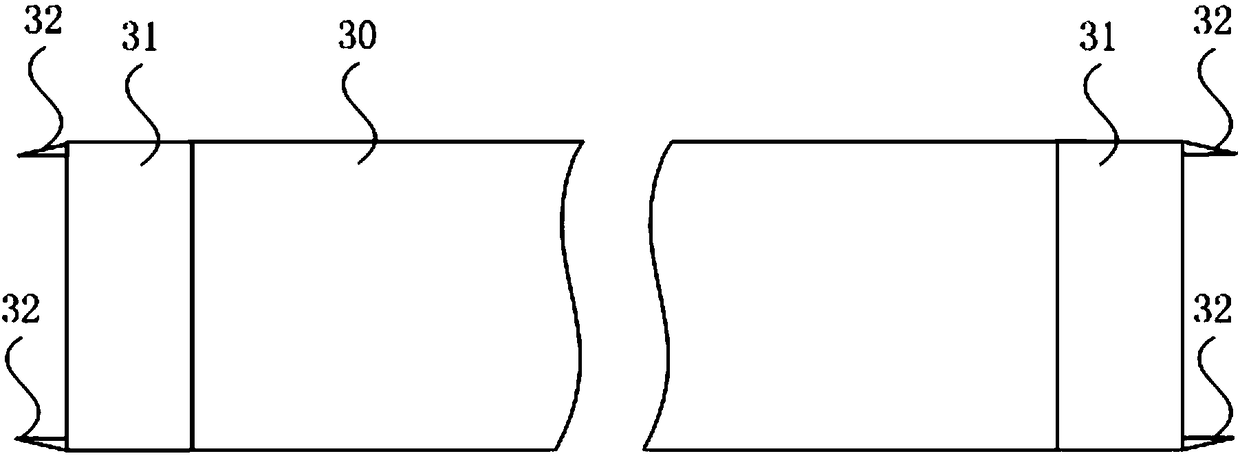

[0027] see image 3 , The flexible flat cable of the present invention includes a body 30 and terminals 31 disposed at both ends of the body 30 . In this specific embodiment, two terminals 31 are included, and the two terminals 31 are arranged oppositely at both ends of the body 30, for connecting with the control board 40 (see FIG. 5 ) and the printed circuit board 42 (see FIG. 5 ). ) The connector 45 (see FIG. 5) in the electrical connection.

[0028] The body 30 includes a conductive metal wire (not shown in the drawing) and a base material (not shown in the drawing) covering the conductive metal wire, and the conductive metal wire is connected to the terminal 31 .

[0029] Each terminal 31 is provided with a clamp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com