Structure for fixing nuts to surface shell and mobile terminal

A fixed structure, mobile terminal technology, applied in the direction of telephone structure, telephone communication, electrical components, etc., can solve the problems of increasing labor costs, high mold precision requirements, affecting yield, etc., to avoid complex nut fixing structures and reduce molds. Accuracy requirements and the effect of improving installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

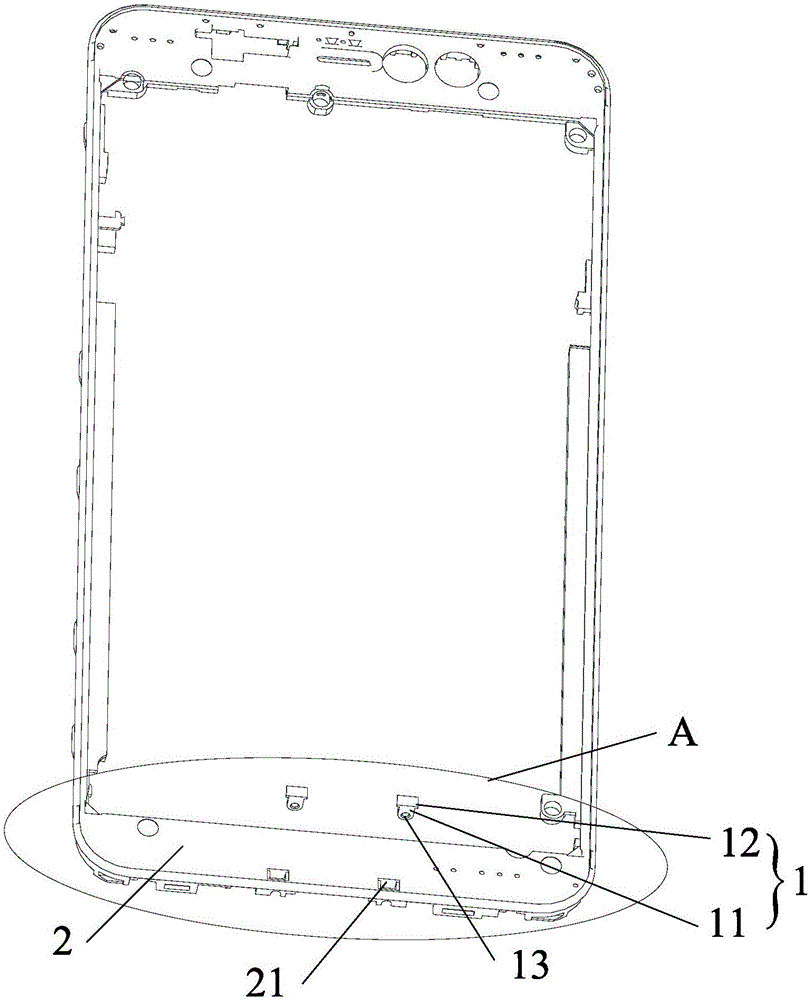

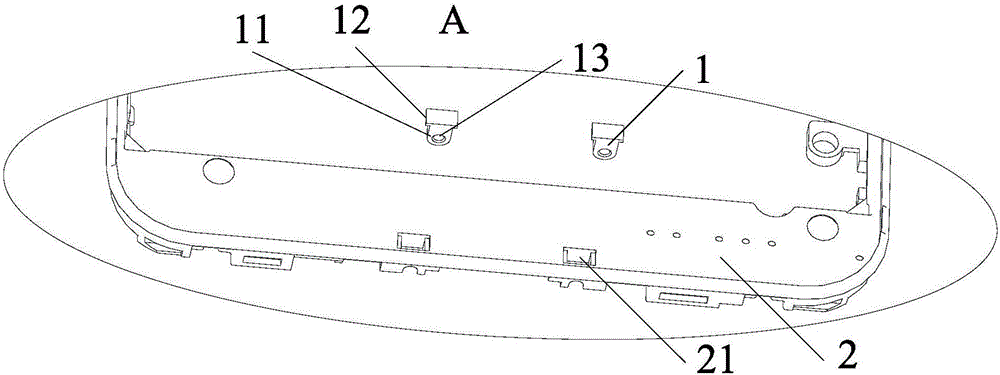

[0051] A fixing structure of a nut 1 on a face shell 2 is used for a mobile terminal. The fixing structure of a nut 1 on a face shell 2 includes a nut 1 and a face shell 2 . The nut 1 has a body 11 and a stopper 12 arranged on the body 11. The body 11 has a threaded hole 13; the face shell 2 is provided with a mounting groove 21 for installing the nut 1, and the side wall of the mounting groove 21 is provided with a limiter. The matching part 213 cooperates with the limiting part 12 and the limiting matching part 213 to limit the movement of the nut 1 relative to the face shell 2 .

[0052] Preferably, as Figure 1 to Figure 7 As shown, the main body 11 extends toward the side wall of the mounting groove 21 to form a limiting portion 12; the mounting groove 21 includes a first end portion 211 and a second end portion 212 that are oppositely arranged and communicated, and the first end portion 211 The cross-sectional area is larger than the cross-sectional area of the second...

Embodiment 2

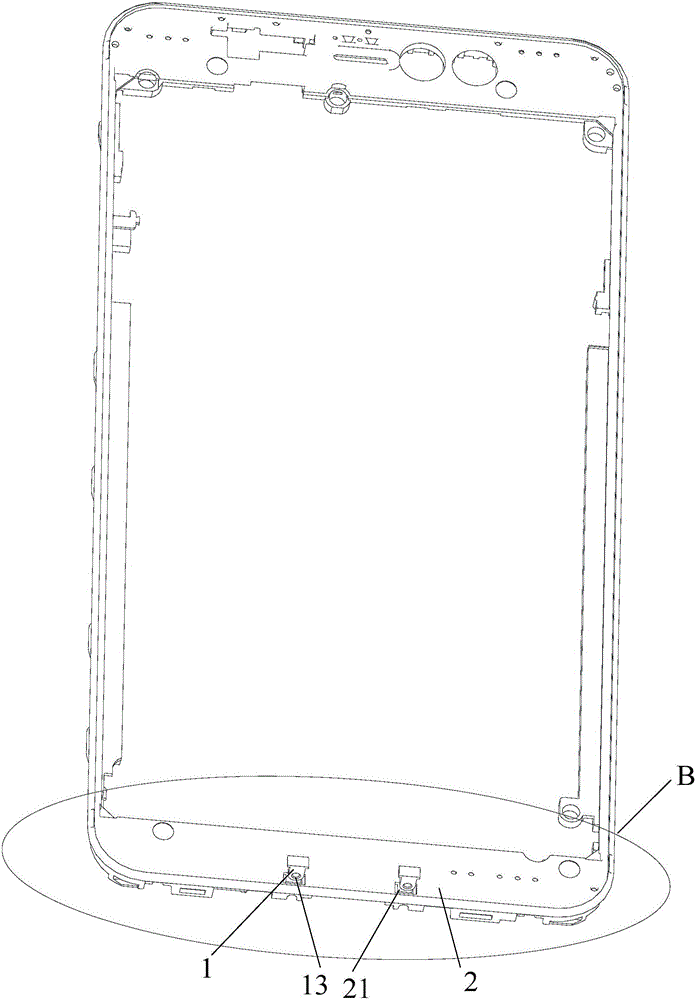

[0069] The difference from Embodiment 1 is that, as Figure 8 and Figure 9 As shown, the body 11 is recessed away from the side wall of the mounting groove 21 to form a limiting portion 12 , and the side wall of the mounting groove 21 protrudes toward a direction close to the body 11 to form a limiting fit portion 213 .

[0070] In the above embodiment, the inner wall surface of the side wall of the installation groove 21 protrudes to form a circumferential protrusion, or forms a plurality of protrusions. The direction of the wall is recessed to form a corresponding card slot, which is the limiting part 12. After the nut 1 is installed in the installation groove 21, the protrusion is inserted into the card slot. Through the cooperation between the protrusion and the card slot, the nut 1 is in the Fixation on face shell 2.

[0071] Preferably, the protrusion is provided with a guide slope, and the slot is provided with a corresponding guide slope, for example Figure 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com