Process for assembling safe intravenous needle

An assembly process and venous needle technology, which is applied in the field of medical devices, can solve the problems of no safe venous needle assembly process and inapplicability of safe venous needles, and achieve the effect of automatic operation, avoiding process waste, and reducing process waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The following examples are for illustrative purposes only, and are not intended to limit the scope of the present invention.

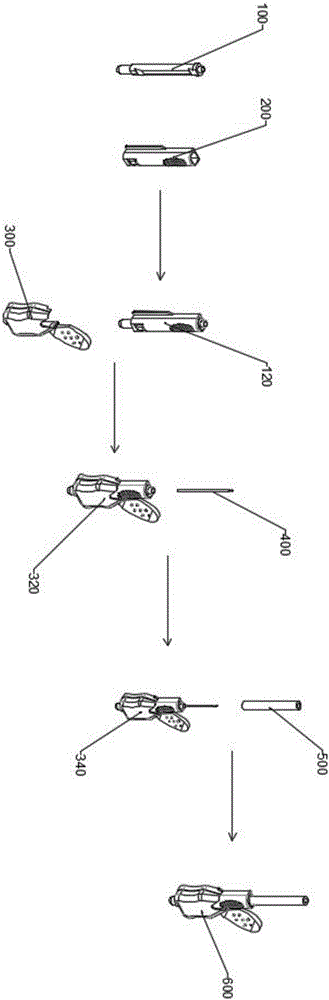

[0075] like figure 2 As shown, the embodiment of the present invention is mainly used for the safety venous needle (600), and the safety venous needle (600) includes the needle seat (100), the safety sliding sleeve (200), the shell (300), the steel needle (400) and the needle The sleeve (500), the needle seat (100), and the safety sliding sleeve (200) are assembled to form an intermediate assembly (120), and the intermediate assembly (120) and the shell (300) are assembled to form an intermediate assembly (320) , the intermediate assembly two (320) is assembled with the steel needle (400) to form the intermediate assembly three (340), and the intermediate assembly three (340) is assembled with the needle cover (500) to obtain the final product safe intravenous needle (600).

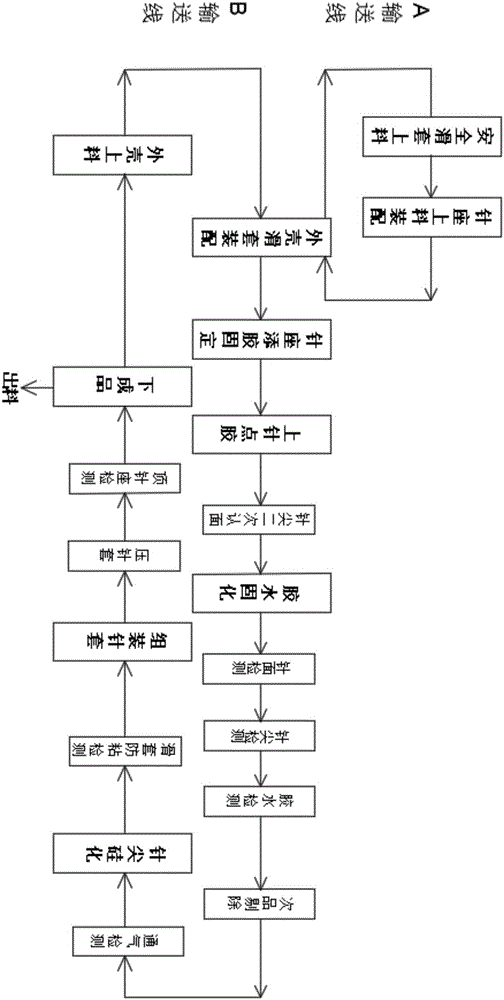

[0076] like figure 1 Shown is the process flow chart of the embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com