Multifunctional road pavement groover

A multi-functional, slotting machine technology, used in roads, roads, road repair and other directions, can solve the problems of uncomfortable wet and slippery road operations, labor-intensive workers, and single function of the slotting machine, achieving excellent dust removal effect and complete dust removal. , the effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention will be described below in conjunction with examples. The examples cited are only used to explain the present invention and are not used to limit the scope of the present invention.

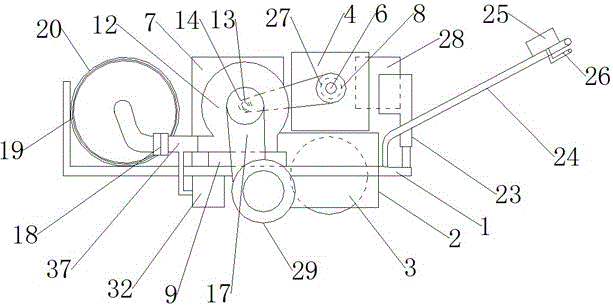

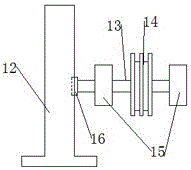

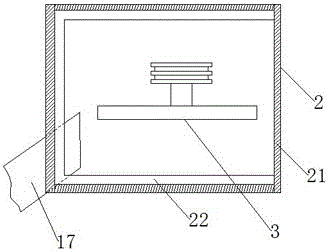

[0031] Such as Figure 1-6 As shown, a multifunctional road surface grooving machine includes a frame 1, the frame 1 is provided with a knife drum mounting housing 2, and the knife drum mounting housing 2 is equipped with a grooving knife drum 3, and the machine The upper part of the frame 1 is provided with an engine 4, the engine 4 is provided with a first output shaft 5 and a second output shaft 6, the engine 4 is connected to an oil tank 7, the first output shaft 5 is provided with an electromagnetic clutch 27, and the second output shaft 6 is provided with a first pulley 8, the front end of the rack 1 is provided with a fan mounting frame 9, the fan mounting frame 9 is provided with a vertical mounting hole 10 and a horizontal mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com