Double-plate-connected super-high-rise assembled building

A super-high-rise and plate connection technology, which is applied in the direction of architecture and building structure, can solve the problems of lengthening construction period and restricting the construction speed of prefabricated buildings, so as to achieve fast construction speed, improve horizontal shear resistance, and reduce horizontal sideways effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

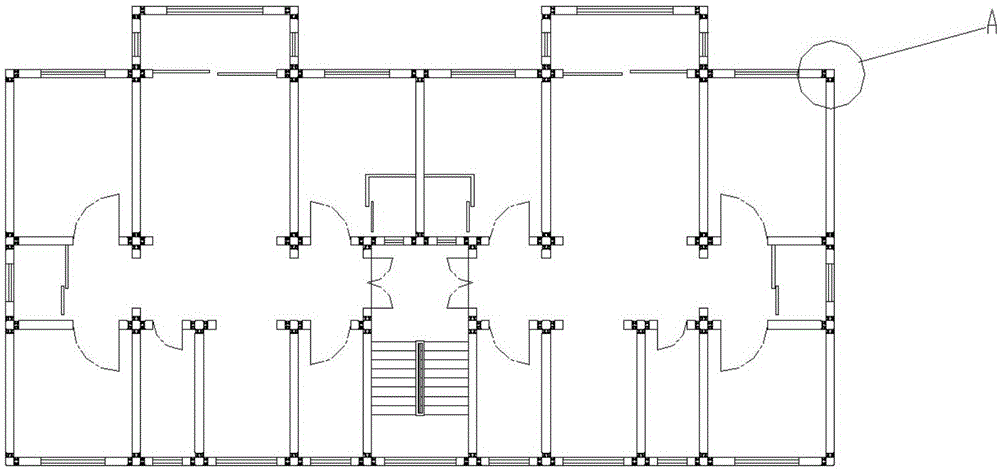

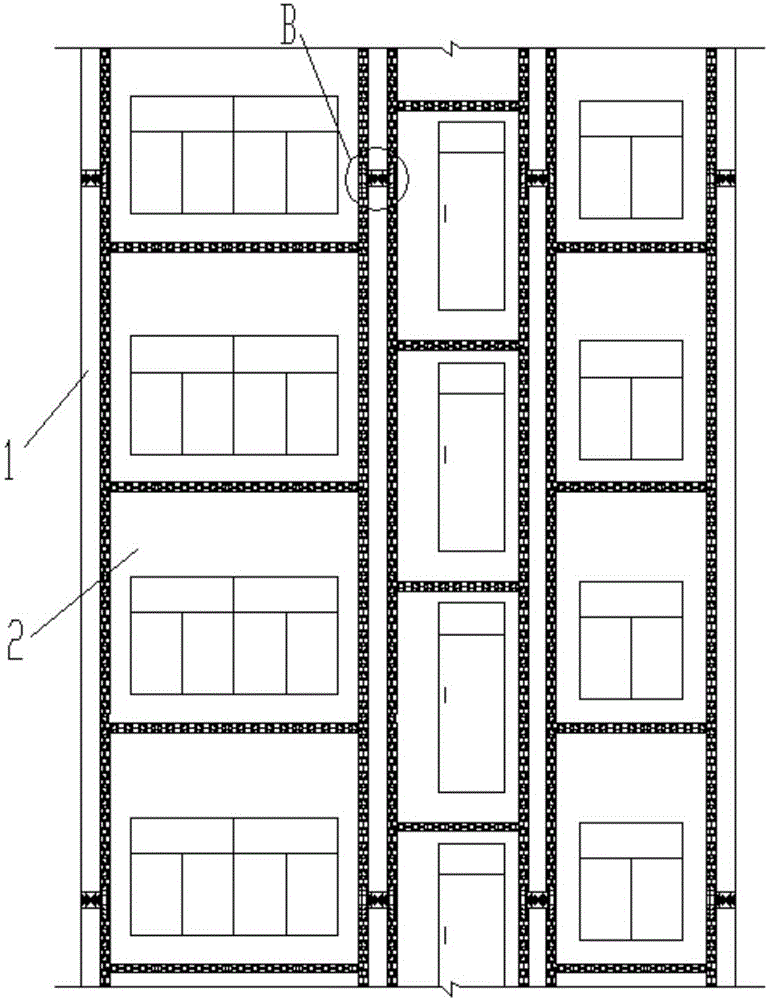

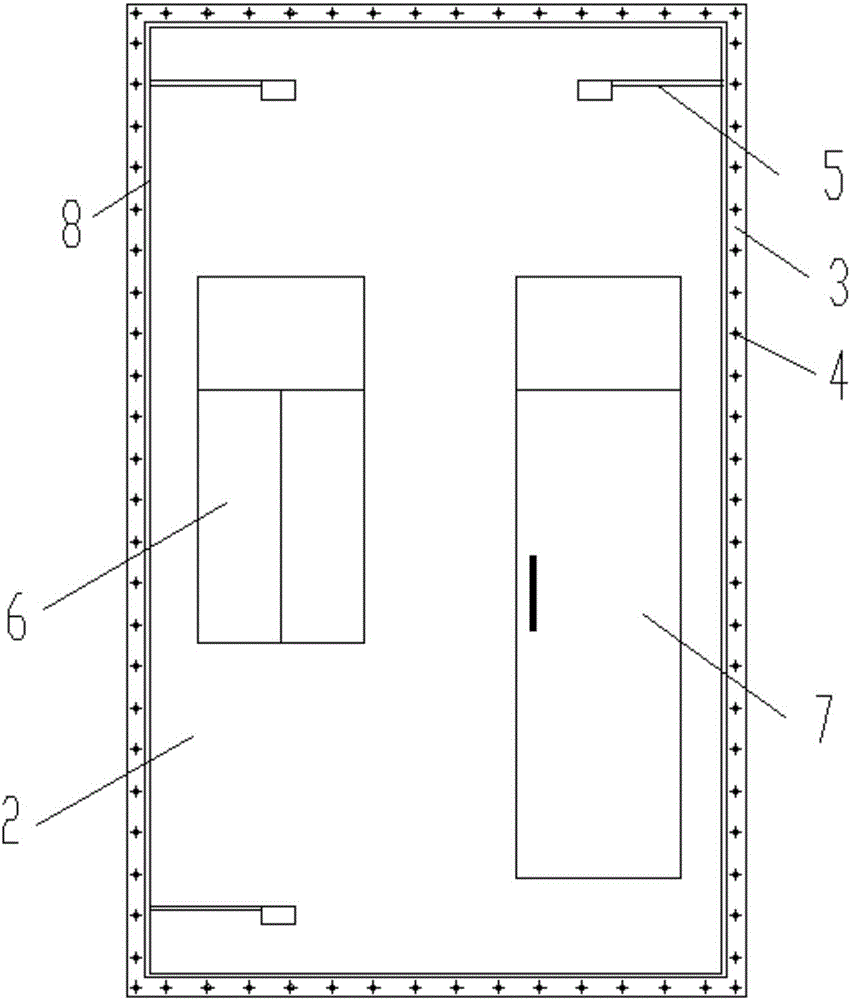

[0046] The present invention provides a super-high-rise prefabricated house with two-board connection, such as figure 1 and figure 2 As shown, it is formed by interconnecting the wall panel 2, the floor panel and the column body 1, wherein, the side end surface of the wall panel 2 is connected to the column body 1, and the side end surface of the floor panel is connected to the side end surface of the wall panel 2. In particular, the shear wall structure in the form of a giant lattice column is formed by connecting the wall panel 2 and the column body 1, which improves the horizontal shear resistance capacity and construction speed of the super high-rise prefabricated building.

[0047] In order to illustrate the composition of the present invention more clearly, the specific structures of the wall panel 2, the column body 1 and the connection nodes between them will be described in detail below.

[0048] in, figure 1 and figure 2 The wall panels used in 2 are divided int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com