Guide star-based large-scale telescope field assembly and adjustment detection device and method

A technology for detection devices and telescopes, applied in measuring devices, machine/structural component testing, optical instrument testing, etc., can solve problems such as unsatisfactory light source stability requirements, poor reliability star targets, etc., and meet the requirements of light source stability , high development cost and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

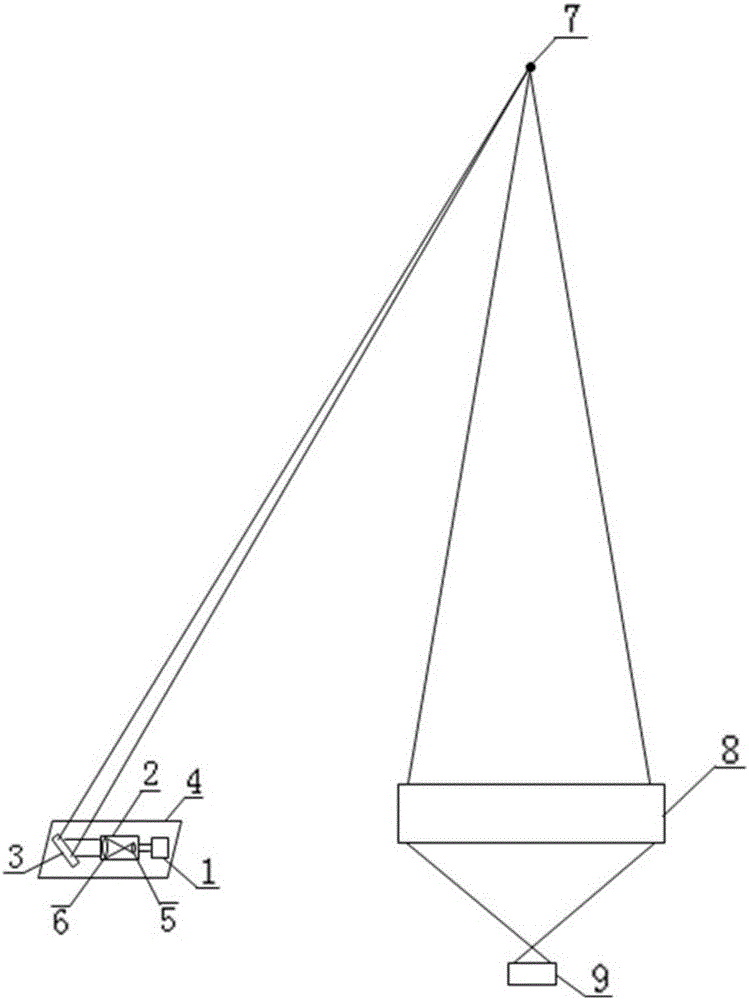

[0036] See attached figure 1 , the on-site assembly and adjustment detection device for a large telescope based on a guide star of the present invention includes a high-performance laser 1, a laser beam expander telescope 2, a precision pointing mirror 3 and a wavefront sensor 9;

[0037] The wavefront sensor 9 is located behind the focal point of the inspected large telescope 8;

[0038] The laser beam emitted by the high-performance laser 1 is expanded by the laser beam expander telescope 2, and then reflected by the precision pointing mirror 3 to the sodium atomic layer 100 km away from the ground, and the sodium atomic resonance is excited to obtain the sodium laser guide star 7, and the sodium laser guide star 7 The star point enters the center of the detector field of view of the wavefront sensor 9;

[0039] The optical axis of the laser reflecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com