Electrically functional thin-film composite structures for application to substrates

A composite structure, conductive film technology, used in household appliances, electrical components, other household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

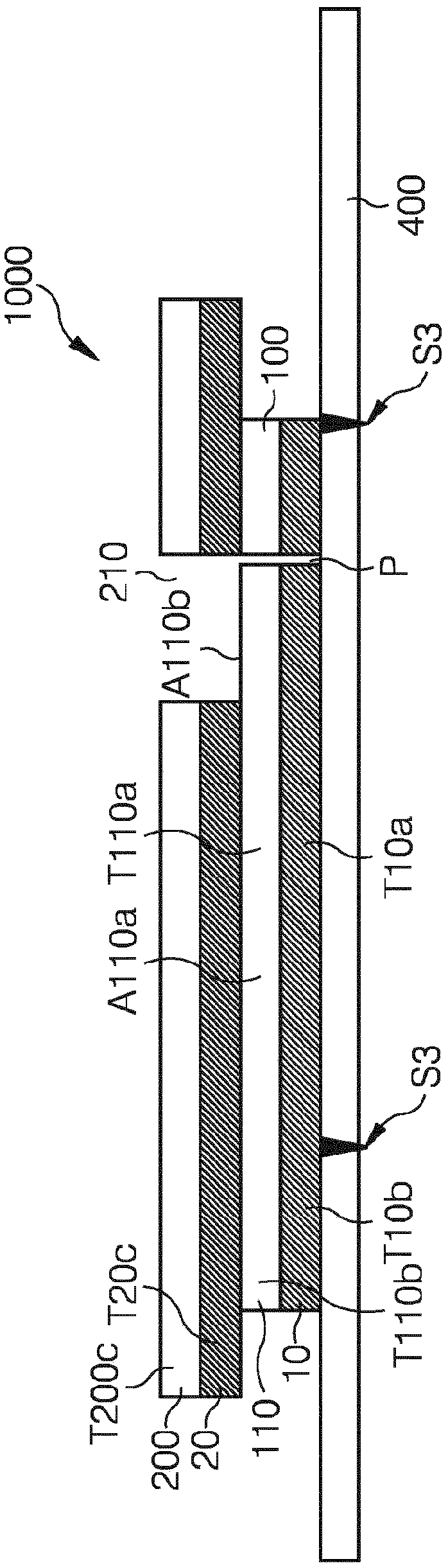

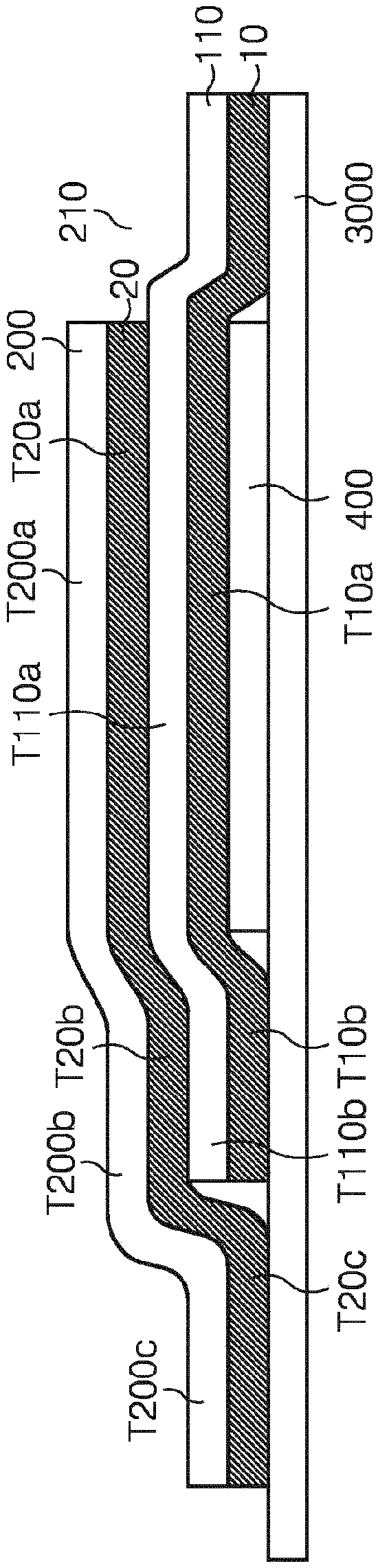

[0031] figure 1 A cross-sectional view of one embodiment 1000 of an electrically functional thin film composite structure is shown. The film composite comprises at least one conductive structure 110 and a connecting layer 10 which is arranged on the underside of the at least one conductive structure. The connection layer 10 has an adhesive function in order to apply at least one conductive structure to the substrate. Furthermore, the film structure has a film ply 200 and a connecting layer 20 . The connection layer 20 is arranged between the upper side of the at least one conductive structure 110 and the film ply 200 . The connection layer 20 has an adhesive effect by which the film ply 200 is attached to at least one conductive structure. The connecting layer 10 and the connecting layer 20 can be formed, for example, as an adhesive coating or as an adhesion promoter, in particular as a lacquer layer.

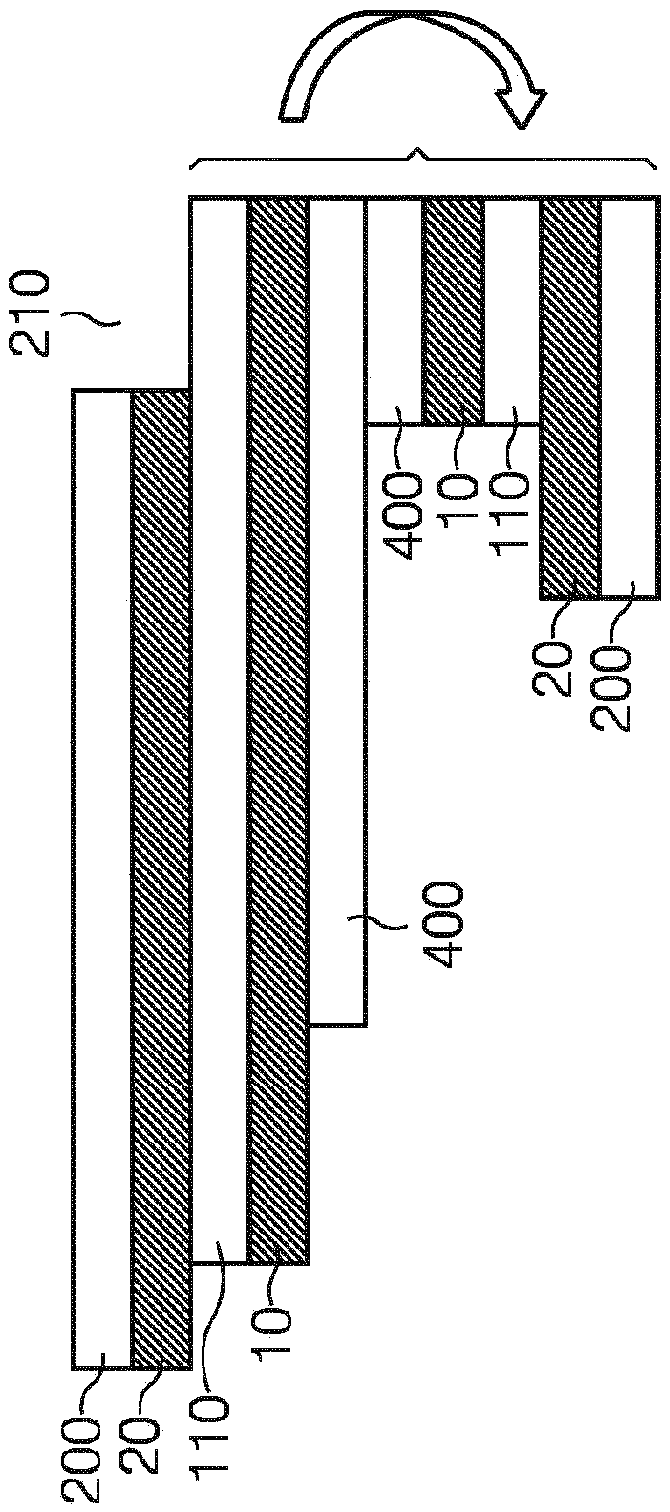

[0032]Film composite structure 1000 also includes a carrier film 400 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com