Automatic seedling distributing apparatus of transplanting machine

A seedling separating device and transplanting machine technology, applied in the field of agricultural machinery, can solve the problems of complex overall structure design, inconvenient disassembly and assembly, and poor versatility, and meet the requirements of multi-row planting, convenient disassembly and assembly, and simple overall structure design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

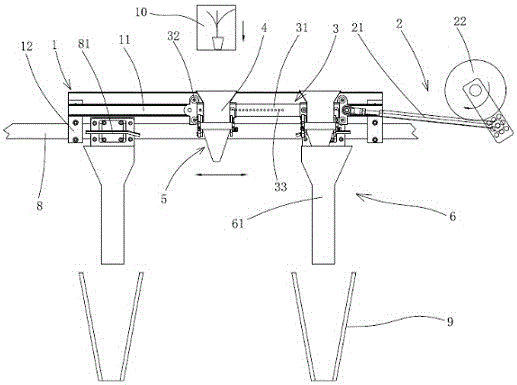

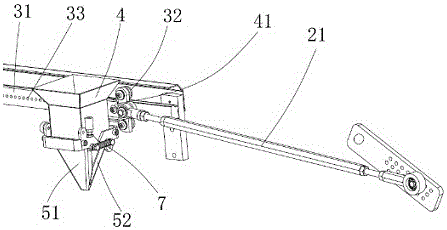

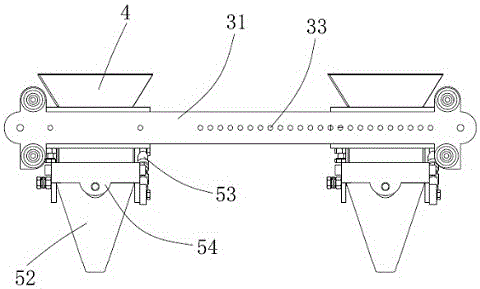

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, this solution includes at least one single-row seedling dividing device. The single-row seedling dividing device includes a slide assembly 1. The slide assembly 1 is provided with a slide assembly 3 capable of reciprocating under the drive of the drive assembly 2. The drive assembly can be A telescopic cylinder or a crank connecting rod structure or other reciprocating drive device that drives the sliding plate assembly 3 to reciprocate. The sliding plate assembly 3 is provided with at least one seedling dividing tube 4 with an open upper end, and the opening at the lower end of the seedling dividing tube 4 is provided with an opening and closing Structure 5, there is at least one seedling falling mechanism 6 under the slide assembly 1, and the seedling falling mechanism 6 is provided with the opening and closing structure 5 when the seedling dividing tube 4 is driven by the driving assembly 2 to move to the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com