A large-flow and long-life roll-type reverse osmosis membrane element

A reverse osmosis membrane, long-life technology, used in reverse osmosis, semi-permeable membrane separation, osmosis/dialysis water/sewage treatment, etc., can solve the problem of concentration polarization effect, pure water production volume needs to be further improved, and dirt adhesion. and other problems, to achieve the effect of increasing the amount of pure water produced, reducing the concentration polarization effect, and increasing the influent flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

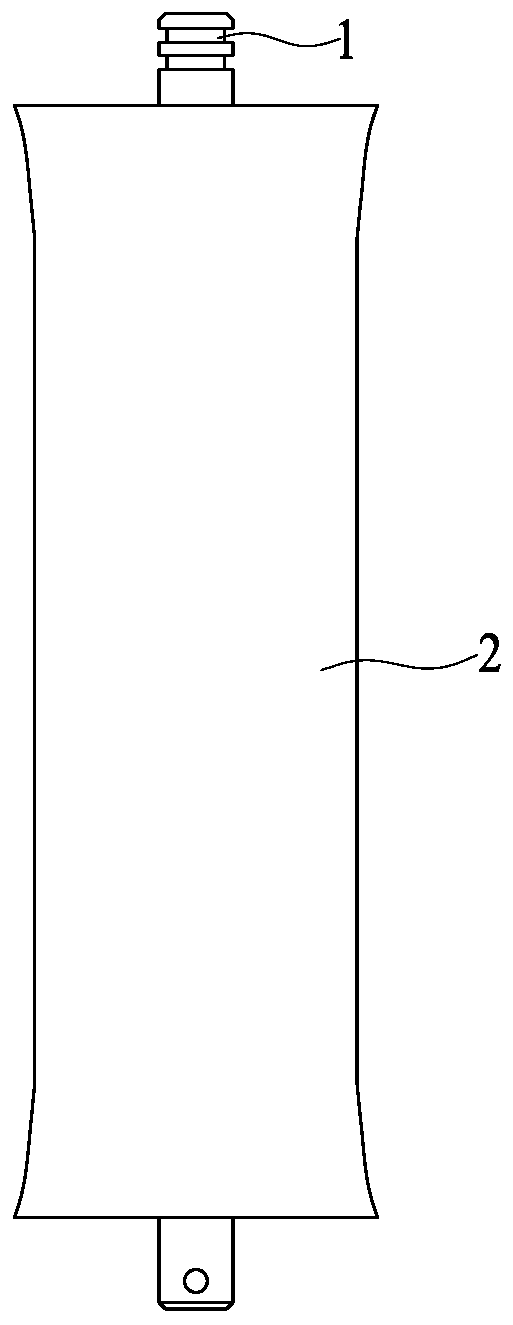

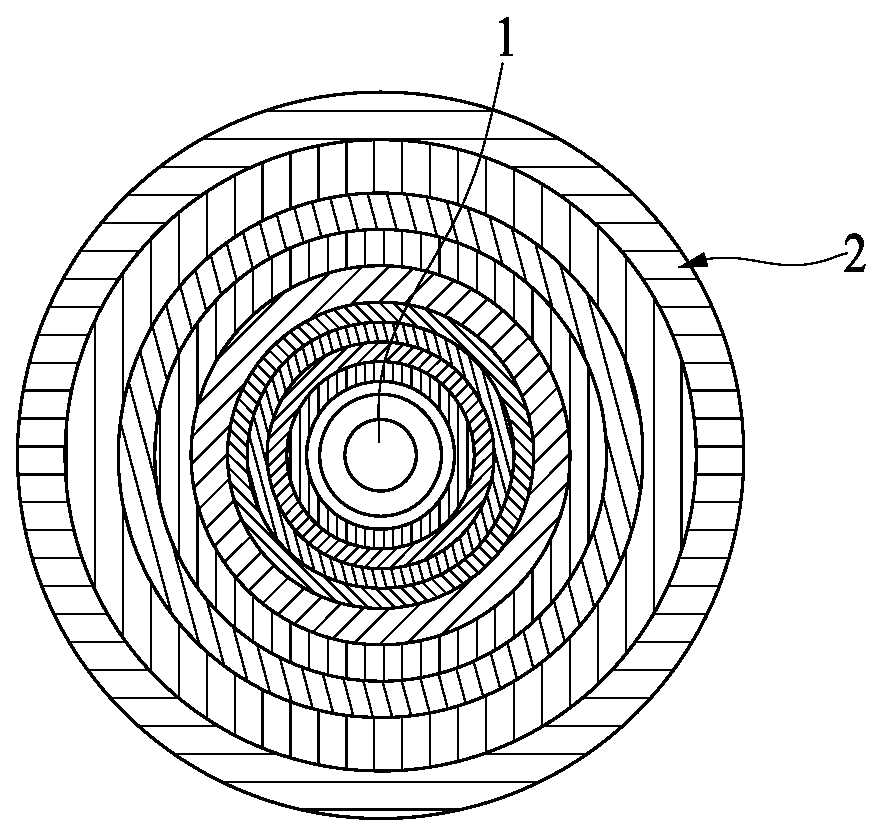

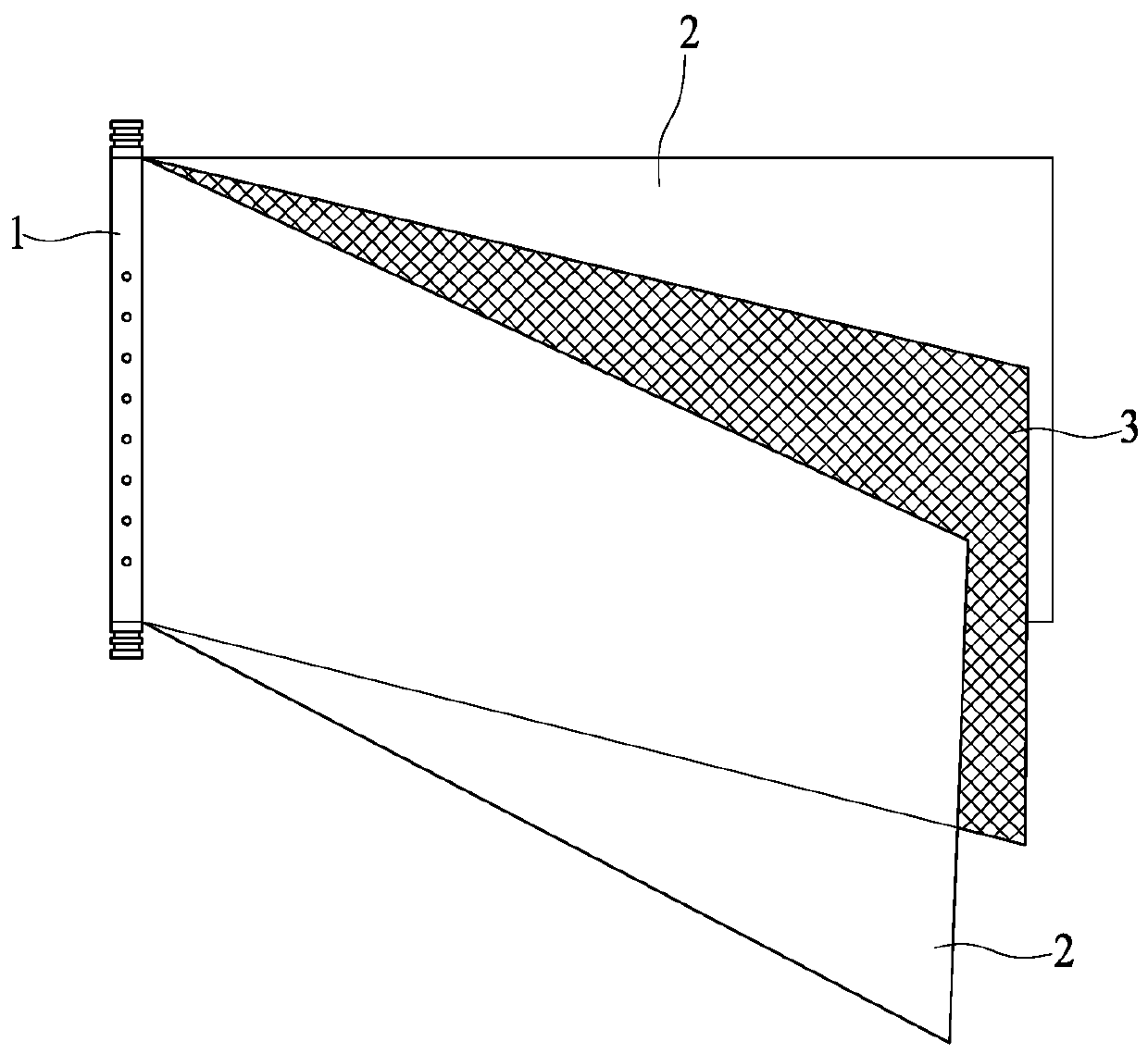

[0024] see Figure 1 to Figure 8 As mentioned above, the present invention discloses a large-flow and long-life roll-type reverse osmosis membrane element, which includes a central pipe 1 , a membrane bag 2 and a water inlet grid 3 .

[0025] A water cavity is formed in the center pipe 1, and a water hole 11 is set on the side wall of the center pipe 1, such as image 3 As shown, a row of water holes 11 is usually provided, and the water holes 11 communicate with the water cavity, which is not shown in the figure.

[0026] The film bag 2 is wound on the central tube 1, and the water inlet grid 3 is arranged between the film bag 2 and the film bag 2. The inside of the film bag 2 communicates with the water cavity through the water hole 11 of the central tube 1. Such as Figure 6 As shown, the film bag 2 can be packaged by a packaging tape 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com