Processing method for inclined lubricating oil grooves in inner ring

The invention relates to a technology of a ring oblique lubricating oil and a processing method, which is applied in the field of machining and can solve the problems of inability to process and difficult to manufacture parts, and achieve the effects of low cost, high efficiency and good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

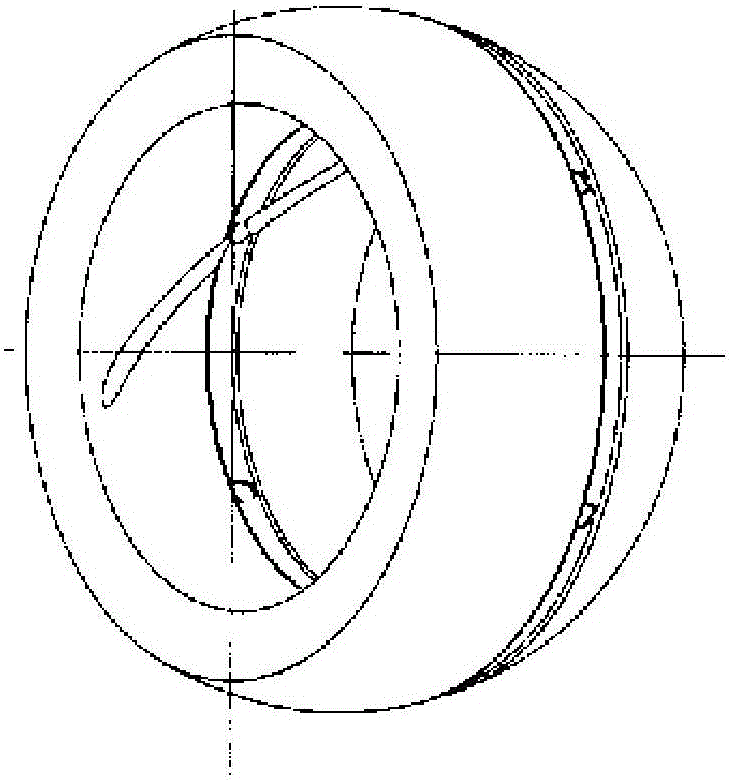

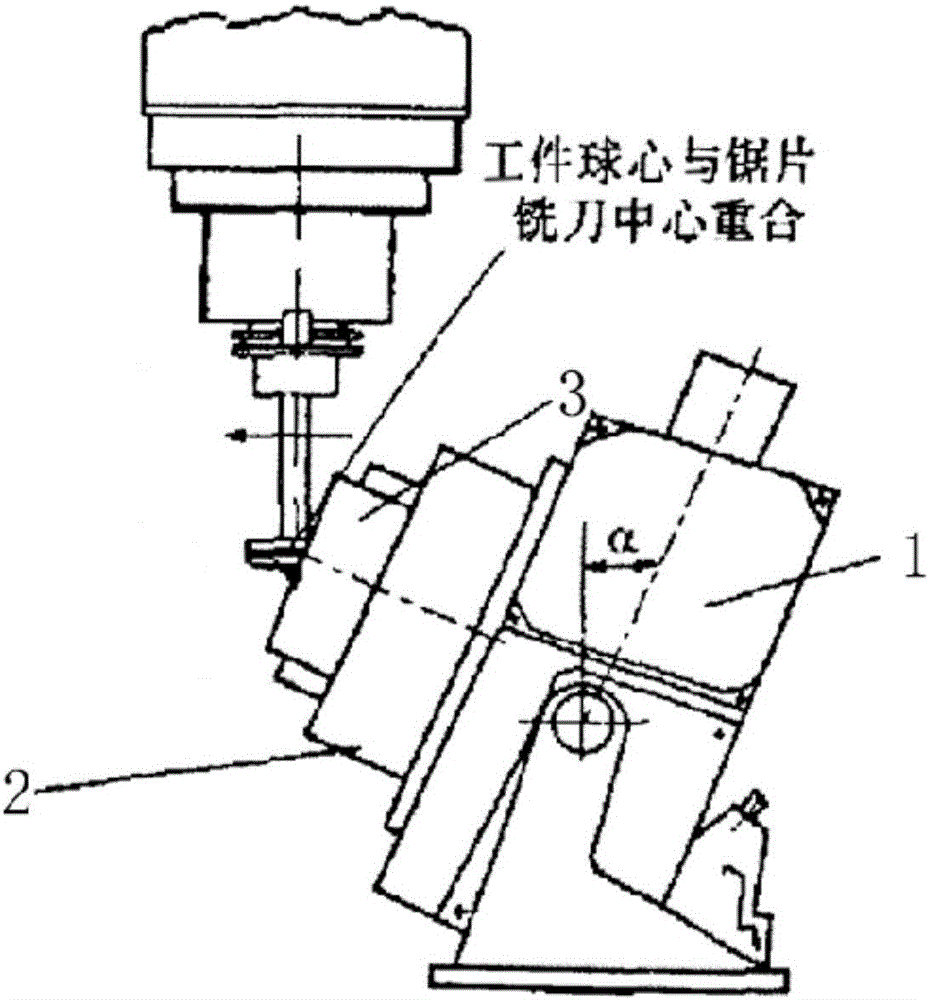

[0016] The lubricating oil groove is a space oil groove on the surface of the inner ring hole, which forms a fixed angle with the axis of the inner ring. Inclined so that the oil groove is in a horizontal position, the cutting force will not be too large when milling with a form milling cutter. Therefore, the diameter D of the saw blade milling cutter is slightly smaller than the ball diameter of the workpiece by 2-3mm, and the cutting edge of the saw blade milling cutter has the same shape as the oil groove. Specific processing methods such as figure 2 As shown, the universal dividing head 1 is manually tilted, and the rotary axis (that is, the fourth axis) is tilted according to the angle α of the lubricating oil groove and then fixed. Three-jaw chuck 2. After the workpiece 3 is clamped, start the CNC machining program, the spindle of the CNC milling machine rotates at the set speed, and the x, y, and z axes move quickly until the center of the saw blade milling cutter co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com