an alignment jig

A jig and ring frame technology, applied in the direction of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve problems such as unfavorable mass production, difficult circuit boards, difficult welding, etc., to achieve convenient operation, simple structure, and avoid offset Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

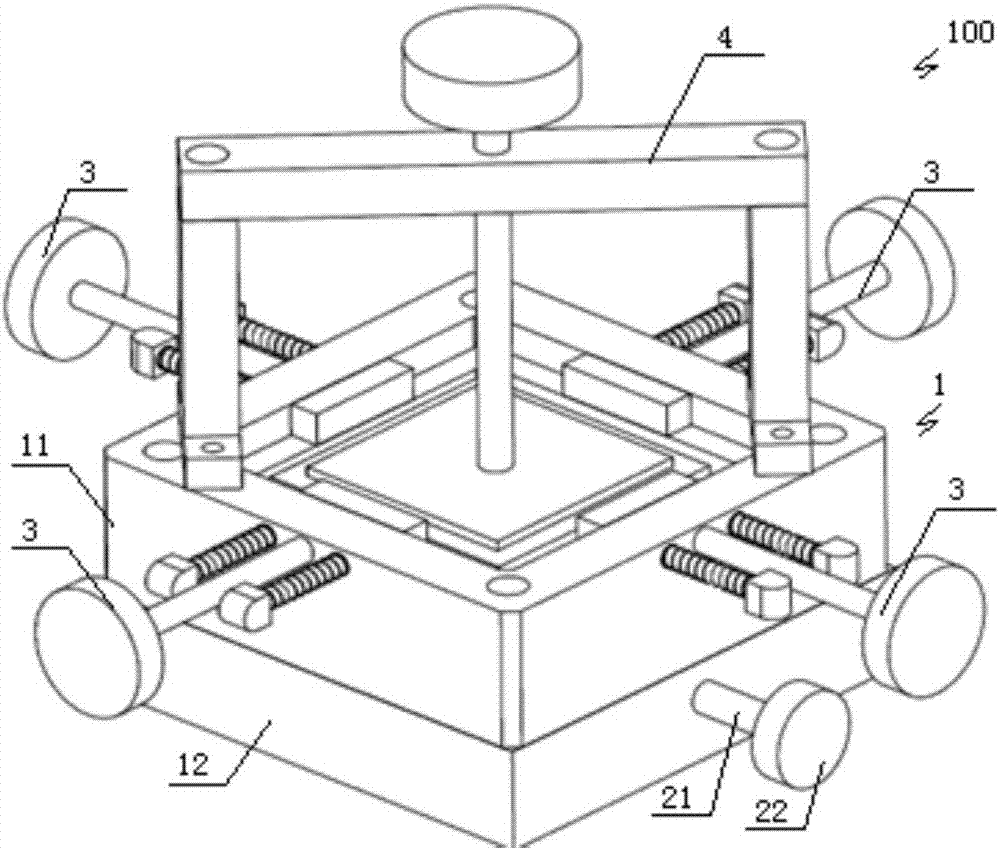

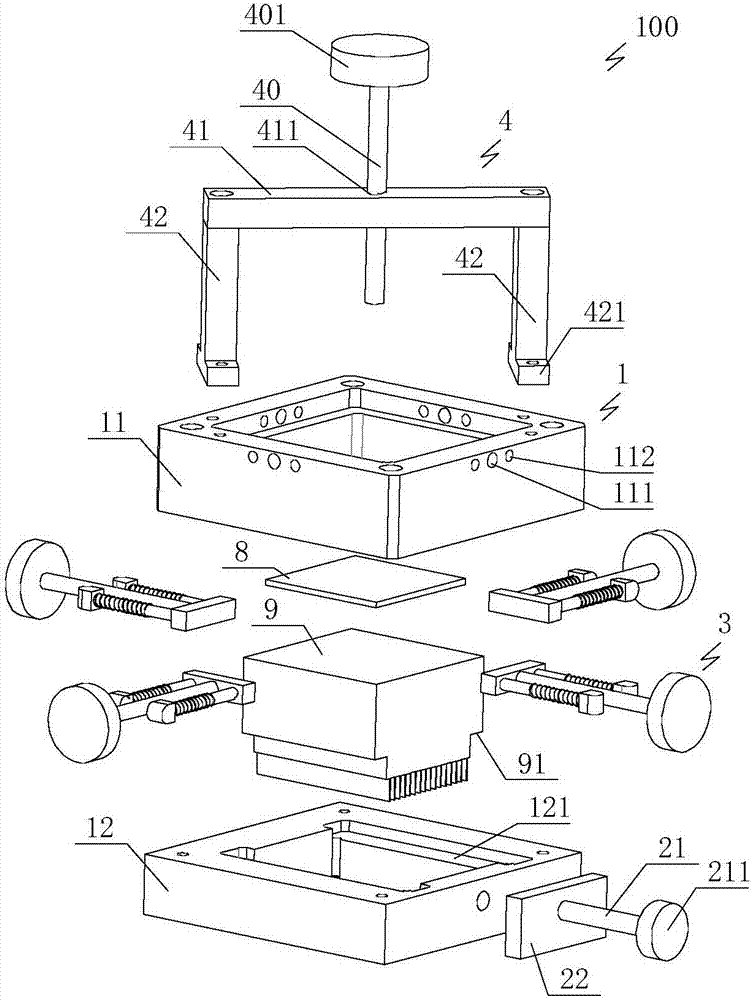

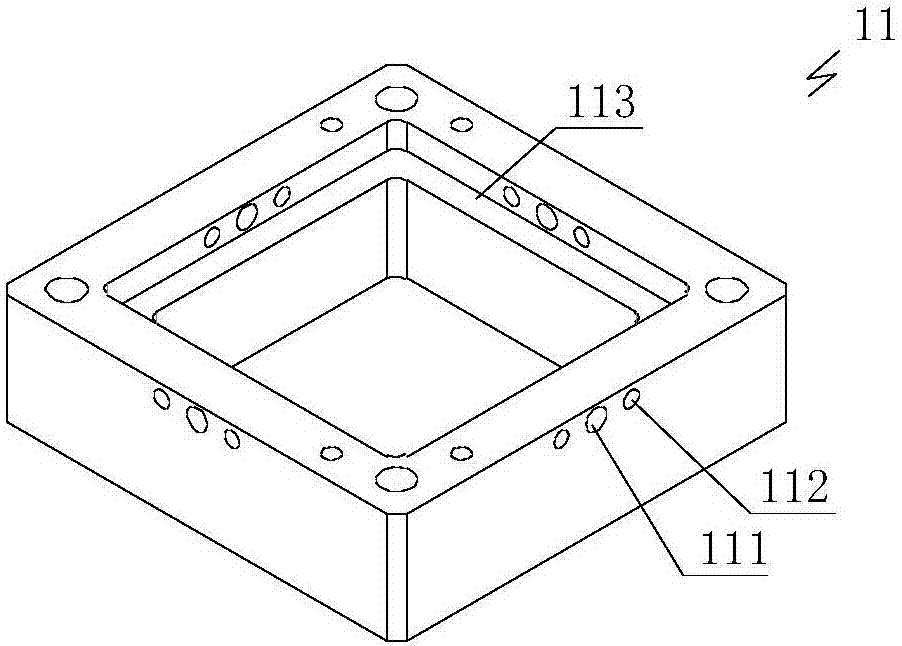

[0025] Such as Figure 1a , Figure 1b As shown, an alignment fixture 100 provided by the present invention includes an annular frame 1, on which a positioning mechanism for fixing a backing 9 containing a circuit board array is arranged. In this embodiment, a plurality of circuit boards The formed circuit board array and the backing 9 are molded by casting, so that the ends (the prior art, not shown in the figure) aligned between the circuit board and the piezoelectric array element 8 form an array corresponding to the piezoelectric array element 8 one-to-one , and then polish the pouring surface to expose the terminal array (copper core array, prior art, not shown in the figure), and the connection between the terminal copper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com