Finger transmission device of multi-joint robot

A multi-joint robot and transmission device technology, applied in the field of robotics, can solve the problem of less movement of the finger structure of space-driven robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

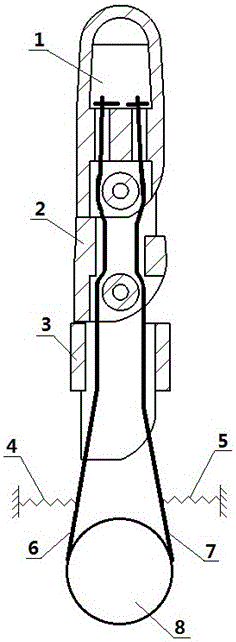

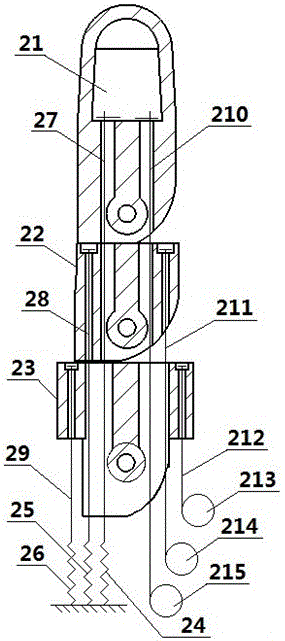

[0017] like figure 2 and image 3 As shown, the technical solution of the present invention is to design a multi-joint robot finger transmission device, including a first finger joint 21, a second finger joint 22, a third finger joint 23, a return spring one 24, a return spring two 25, and a return spring Three 26, rebound rope one 27, rebound rope two 28, rebound rope three 29, tension rope one 210, tension rope two 211, tension rope three 212, motor output disk one 213, motor output disk two 214 And motor output disc three 215.

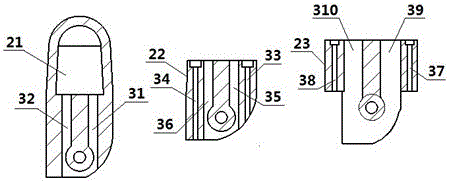

[0018] The first knuckle 21 has a mounting groove 31 for the tension rope 1 of the first knuckle and a mounting groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com