Single-cutting forming line for building plates

A molding processing and production line technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of cumbersome multi-process, small footprint and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

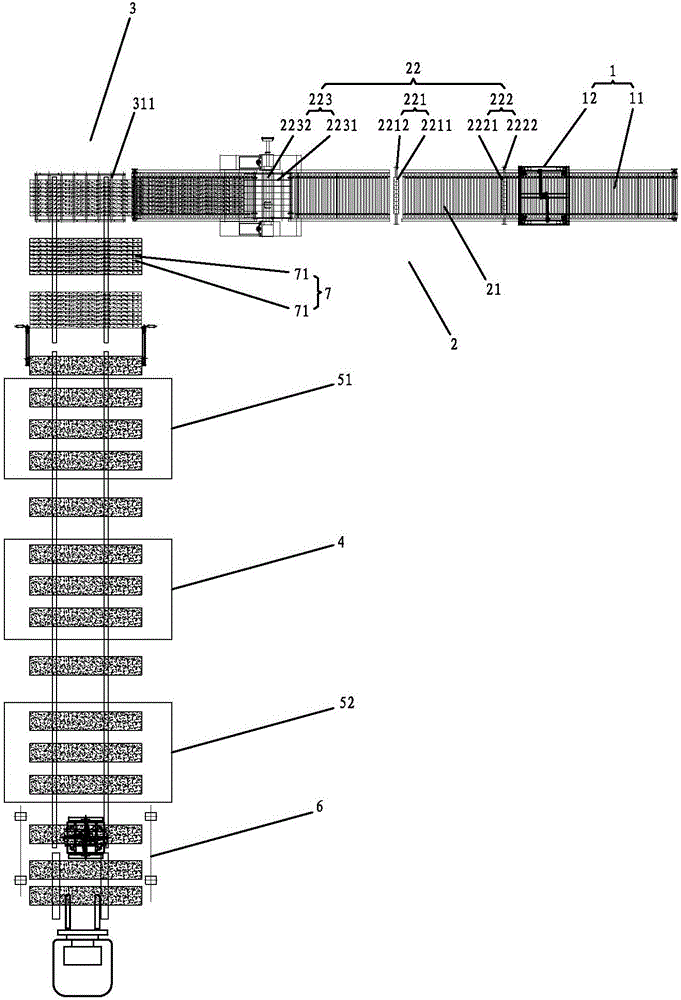

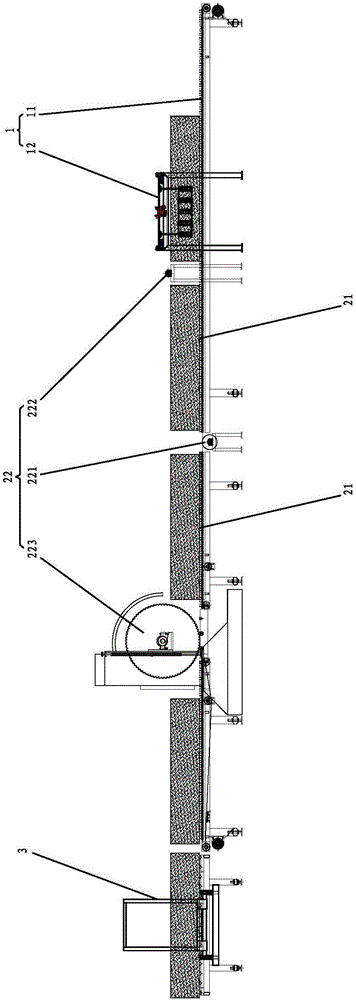

[0052] One-time cutting and forming processing production line of a kind of building plate of the present invention, as Figure 1-8 As shown, it includes a shaping section 1 for shaping the building blocks 7 , a cutting section 2 for cutting the building blocks 7 , and a post-cutting processing section 3 for post-cutting the building blocks 7 arranged in sequence along the production line.

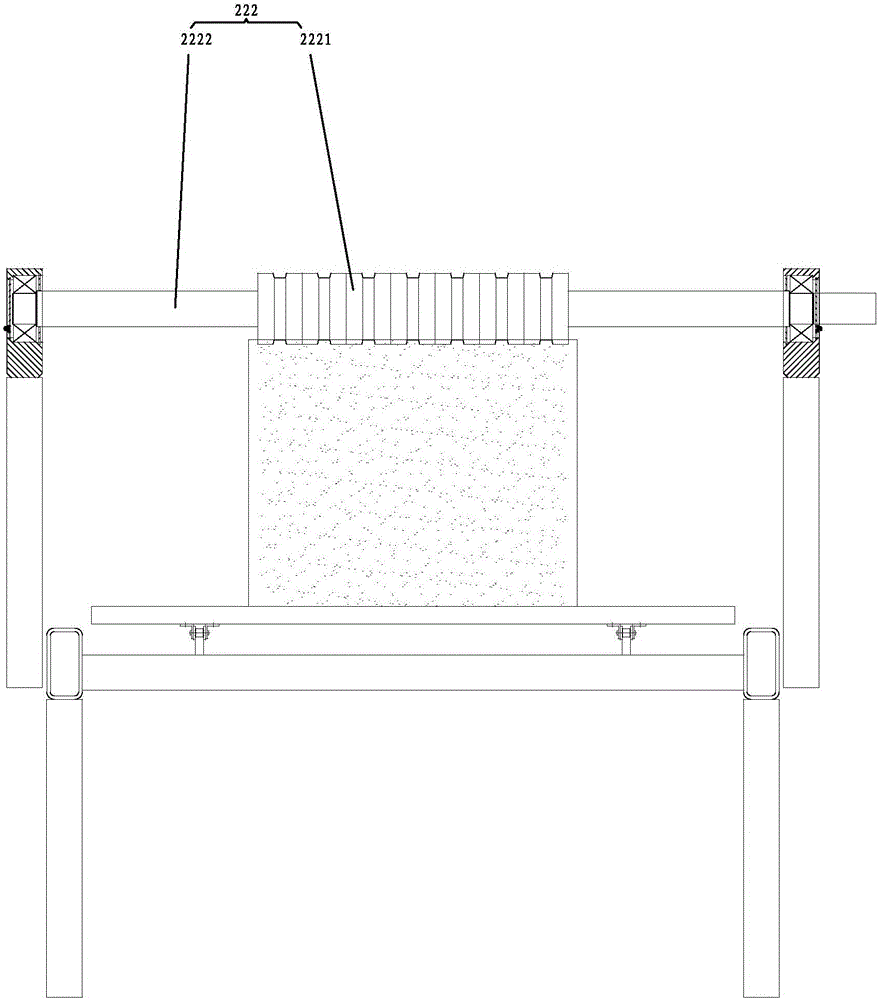

[0053] The shaping section 1 includes a shaping conveying device 11 for carrying and transporting the building blocks 7, and a shaping device 12 for shaping the building blocks 7; The cutting device 22 of cutting; The cutting device 22 comprises the draw-in groove cutting device 221 of cutting the draw-in groove 711 in the upstream, and the card strip cutting device 222 of cutting the card strip 712, and is in the downstream to cut the building b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com