Flame-retardant modified ramie fabric/benzoxazine resin laminated board and preparation method thereof

A technology of benzoxazine and resin layer, which is applied in the field of flame-retardant modified ramie fabric/benzoxazine resin laminate and its preparation, can solve the problems of poor mechanical properties of natural fiber reinforced laminate and achieve good assembly effect , Flame retardant and mechanical properties, and good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

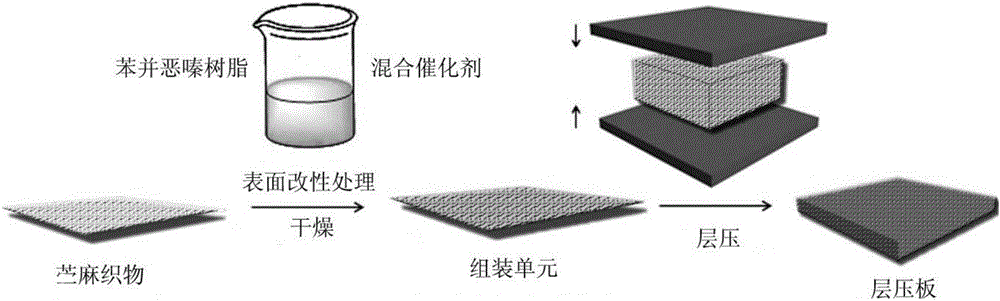

Method used

Image

Examples

Embodiment 1

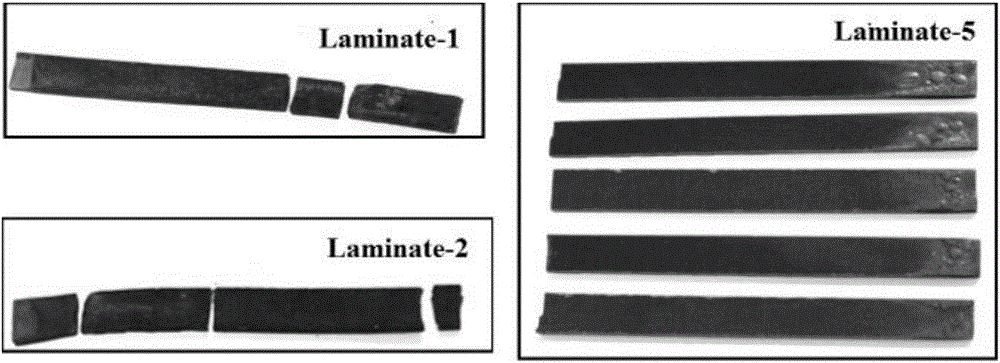

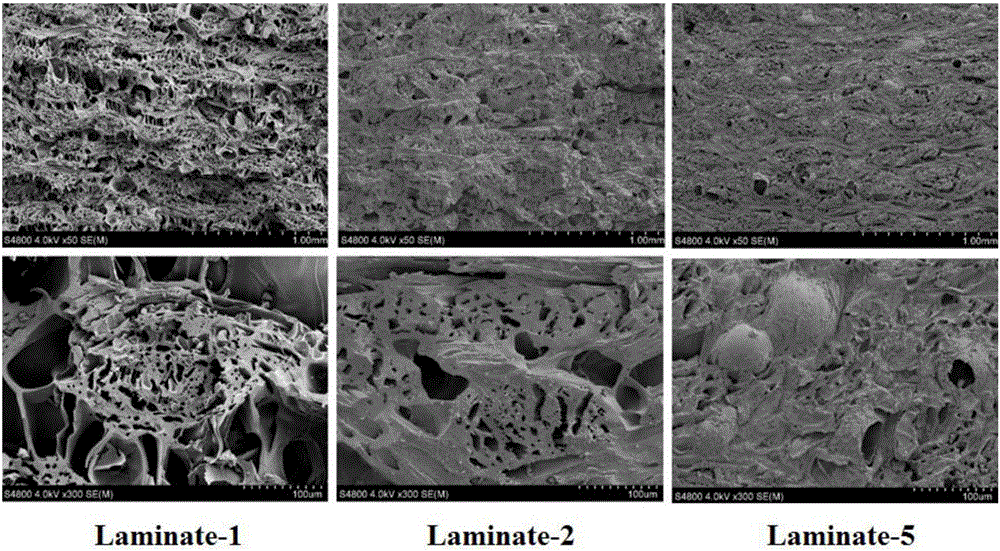

[0042] Soak the ramie fabric in 1.0wt% TMC-27 solution for 30min, take it out and dry it in a blast dryer at 60°C for 15min. The ramie fabric treated with TMC-27 was cut into 250mm×250mm pieces for later use. Add dimethylformamide solvent into the benzoxazine resin monomer at room temperature, dilute until the concentration of the benzoxazine resin monomer solution is 40 wt%, and stir until uniform. Slowly add 5 wt % catalyst methyl p-toluenesulfonate and 2 wt % catalyst iron acetylacetonate by mass of the benzoxazine resin, and stir until uniform. At room temperature, soak the ramie fabric that has been cut and treated with TMC-27 in the benzoxazine resin monomer solution for 1 minute, clamp it with two glass rods to scrape off the excess resin solution on the surface of the fabric, and let it cool at room temperature 60 minutes; the ramie fabric soaked in the benzoxazine resin solution was suspended and transferred to a drying oven, and heated at 100°C for 3 minutes to remo...

Embodiment 2

[0045] Soak the ramie fabric in 2.0wt% TMC-27 solution for 15 minutes, take it out and dry it in a blast dryer at 60°C for 15 minutes. The ramie fabric treated with TMC-27 was immersed in the PEI solution with a mass fraction of 2.0% and the poly(DPA-PDCP) solution with a mass fraction of 3.0% in turn, soaking for 5 minutes each time. Ramie fabric. This process was repeated until 10 double-layer flame-retardant coatings were assembled on the surface of the ramie fabric. Gained ramie fabric is placed in use N 2 Blow-dry the quartz plate, then place it in an 80°C blast oven for 5 minutes, and place it in a desiccator for 7 hours. Cut the PEI / poly(DPA-PDCP) flame retardant finished ramie fabric into pieces of 250mm×250mm for later use. Add toluene solvent into the benzoxazine resin monomer at room temperature, dilute to a concentration of 40 wt% of the benzoxazine resin monomer solution, and stir until uniform. Slowly add 5 wt % catalyst methyl p-toluenesulfonate and 2 wt % c...

Embodiment 3

[0048] Assembling 10 double-layer flame-retardant coatings on the surface of ramie fabric was changed to assembling 20 double-layer flame-retardant coatings on the surface of ramie fabric. Others were the same as in Example 2 to obtain a laminate (Laminate-4).

[0049] The tie layer content (glue content) of the laminate was calculated to be 34.8% by weighing. The limiting oxygen index of the sample was measured with an oxygen index tester, the LOI reached 29.3, and the flame retardancy level reached V1 through the vertical burning test. The mechanical properties of the laminate were tested with a universal material testing machine, and the tensile strength was 60.6MPa, and the bending strength was 101.2MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com