On-board charger, battery liquid cooling system and electric vehicle

An on-board charger and battery system technology, applied in electric vehicles, battery/battery traction, battery/fuel cell control devices, etc., can solve the problems of high cost and occupying the layout space of the whole vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the on-board charger, the battery liquid cooling system and the electric vehicle will be described in detail below in conjunction with the accompanying drawings and embodiments.

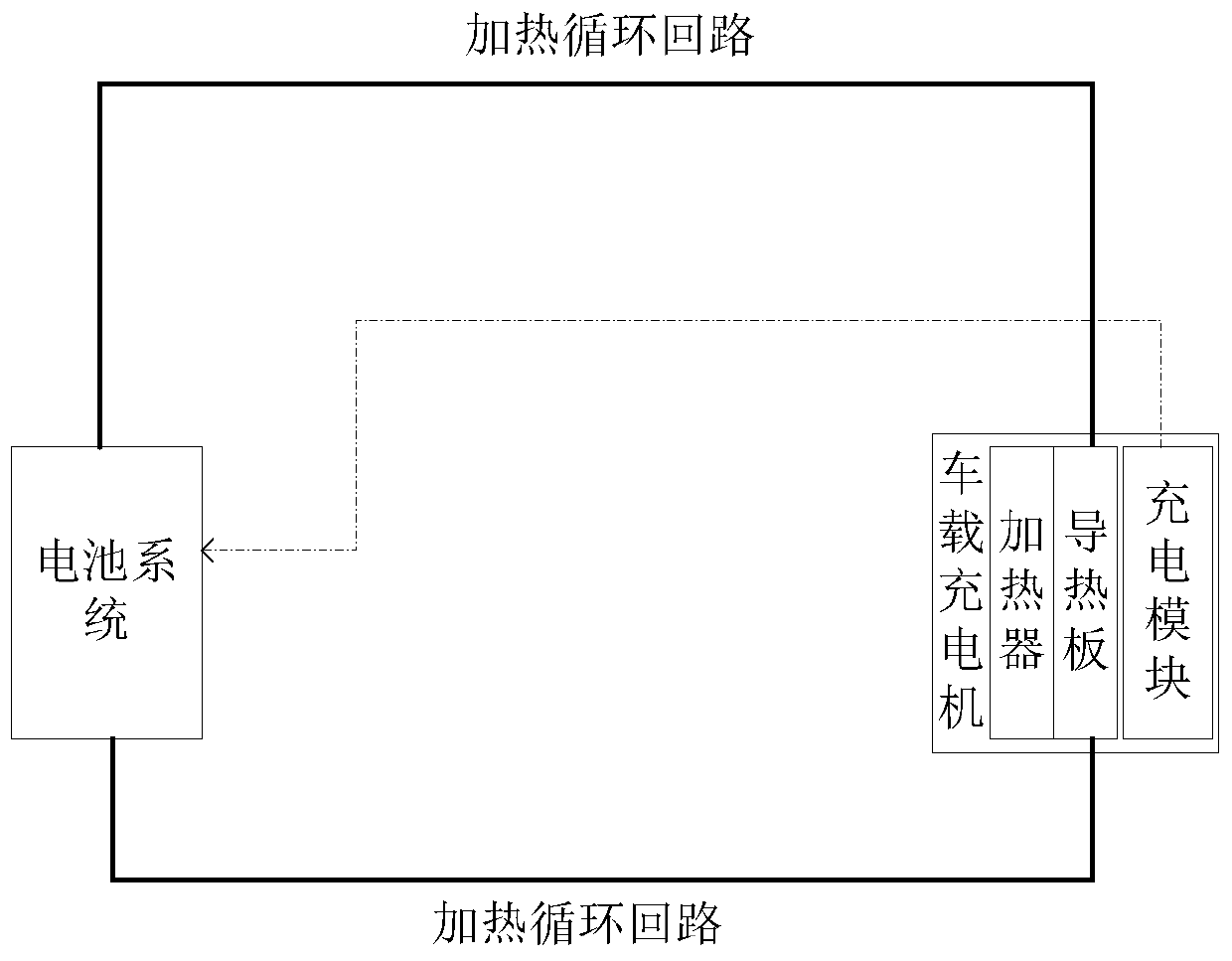

[0020] refer to figure 1 as shown, figure 1 It is a structural schematic diagram of the vehicle-mounted charger of the present invention, which shows the structure of the vehicle-mounted charger and the heating cycle part, including the charging module for charging the battery system (the dotted line in the figure shows the relevant circuit), and the heat conduction plate and heaters;

[0021] The heat conducting plate is connected in series in the heating circulation loop of the battery system;

[0022] The heater is connected to the output terminal of the charging module, and the charging module or the battery system provides power to the heater through the output terminal;

[0023] The heat conduction plate is connected with the heater, and the heat conduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com