A high-efficiency automatic discharge device and its working method

An automatic discharge device, high-efficiency technology, applied in packaging, solid materials, loading/unloading, etc., can solve the problems of high manufacturing and operating costs, troublesome liquid material recovery, complex operating processes, etc., and achieve low manufacturing and operating costs. , The effect of convenient and quick loading and unloading, and the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

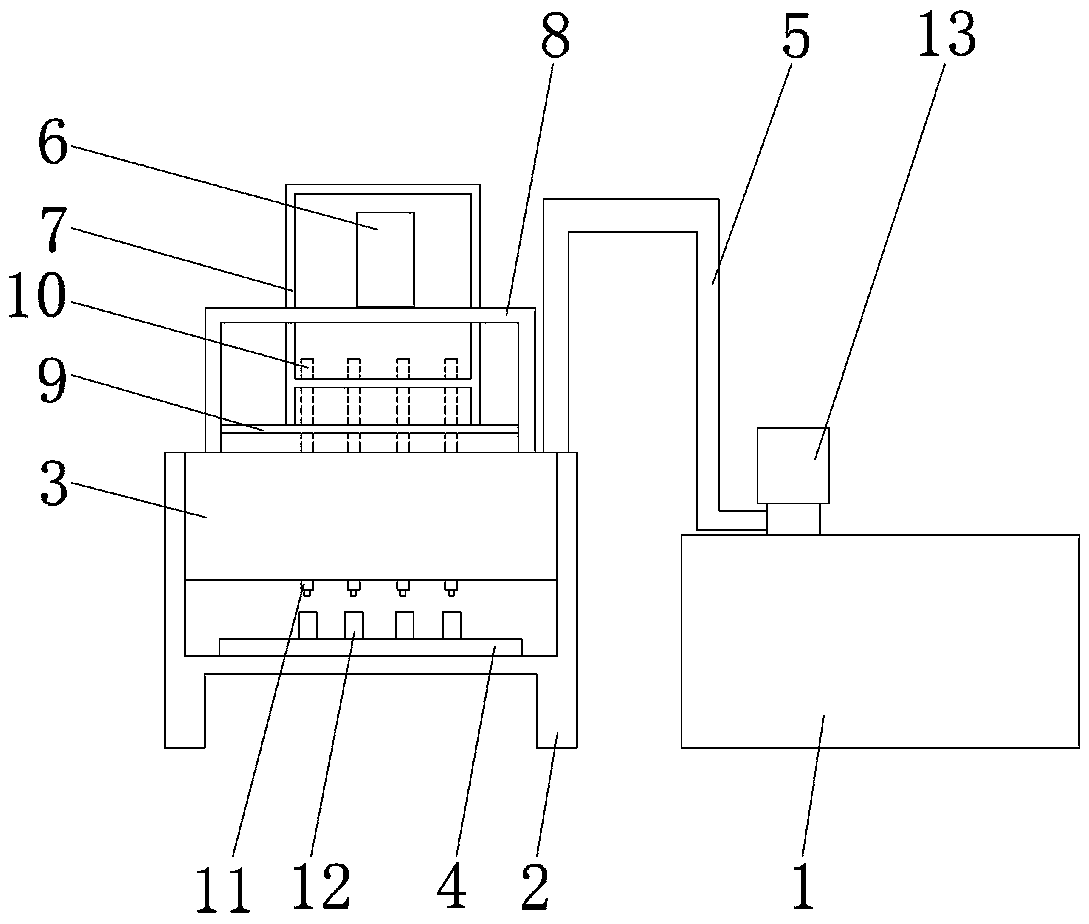

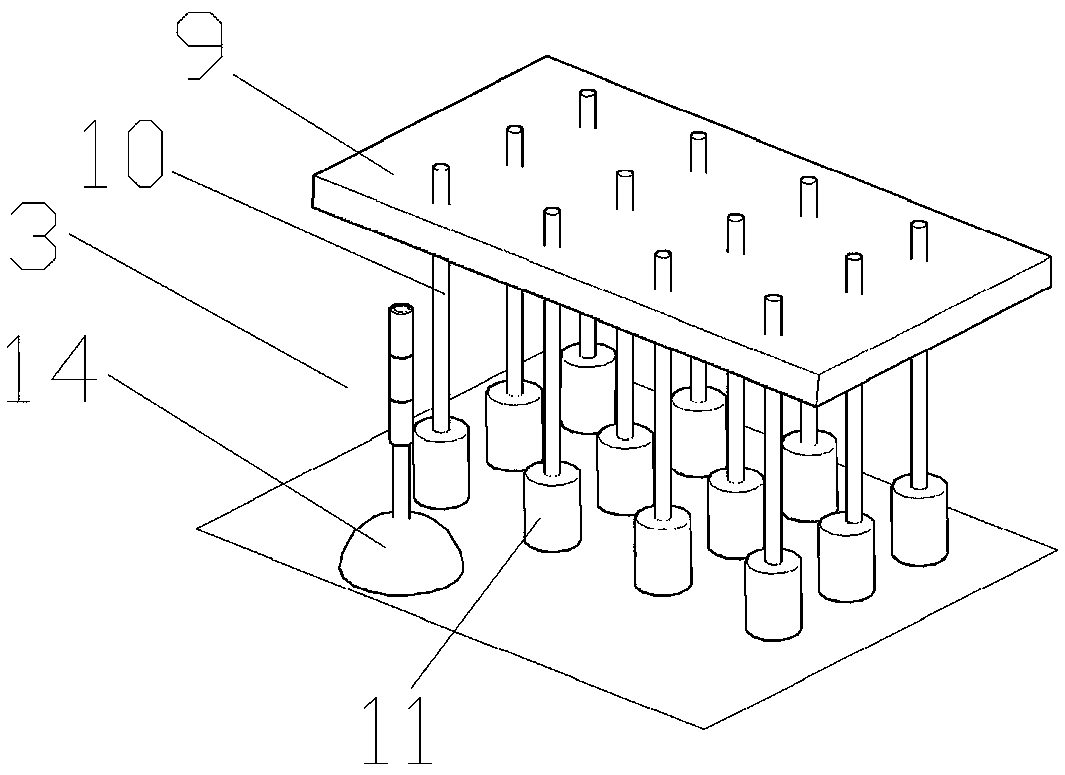

[0032] Such as figure 1 , figure 2 As shown, a high-efficiency intelligent extrusion molding device of this embodiment includes: a storage box 1, a frame 2, a discharge box 3, a material collection box 4, a feeding pipe 5, a cylinder 6, a connecting frame 7, a fixed Seat 8, fixed plate 9, pull rod 10, discharge port 11, material receiving bottle 12, motor 13 and floating ball 14.

[0033] The connection relationship of the above-mentioned components is as follows: the motor 13 is arranged on the top of the material storage box 1, and the two ends of the feed pipe 5 are respectively connected with the discharge box 3 and the storage box 1; the bottom of the discharge box 3 is provided with a Group discharge port 11 and floating ball 14; the lower part of the pull rod 10 is slidingly connected with the discharge port 11, and the top passes through the fixed seat 8 and is connected with the cylinder 6; the surface of the receiving box 4 is inlaid with the discharge port 11 A g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com