Low-level palletizing/depalletizing equipment and method for fermentation trays

A fermentation tray and low-level code technology, which is applied in the direction of destacking, stacking, transportation and packaging of objects, can solve the problems of increased manufacturing cost and undiscovered, and achieves reduced manufacturing cost, easy installation and maintenance, and equipment operation. and safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

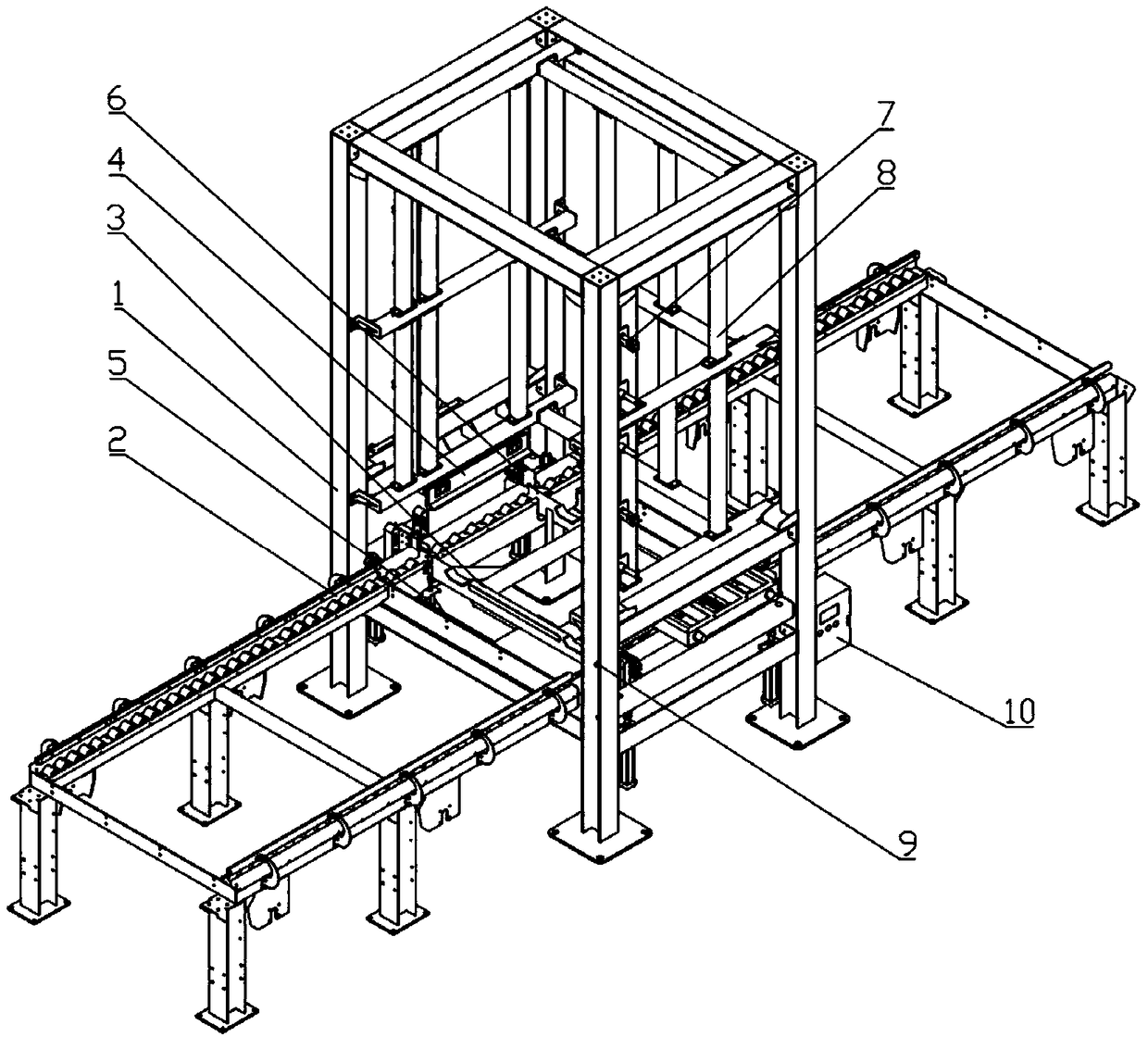

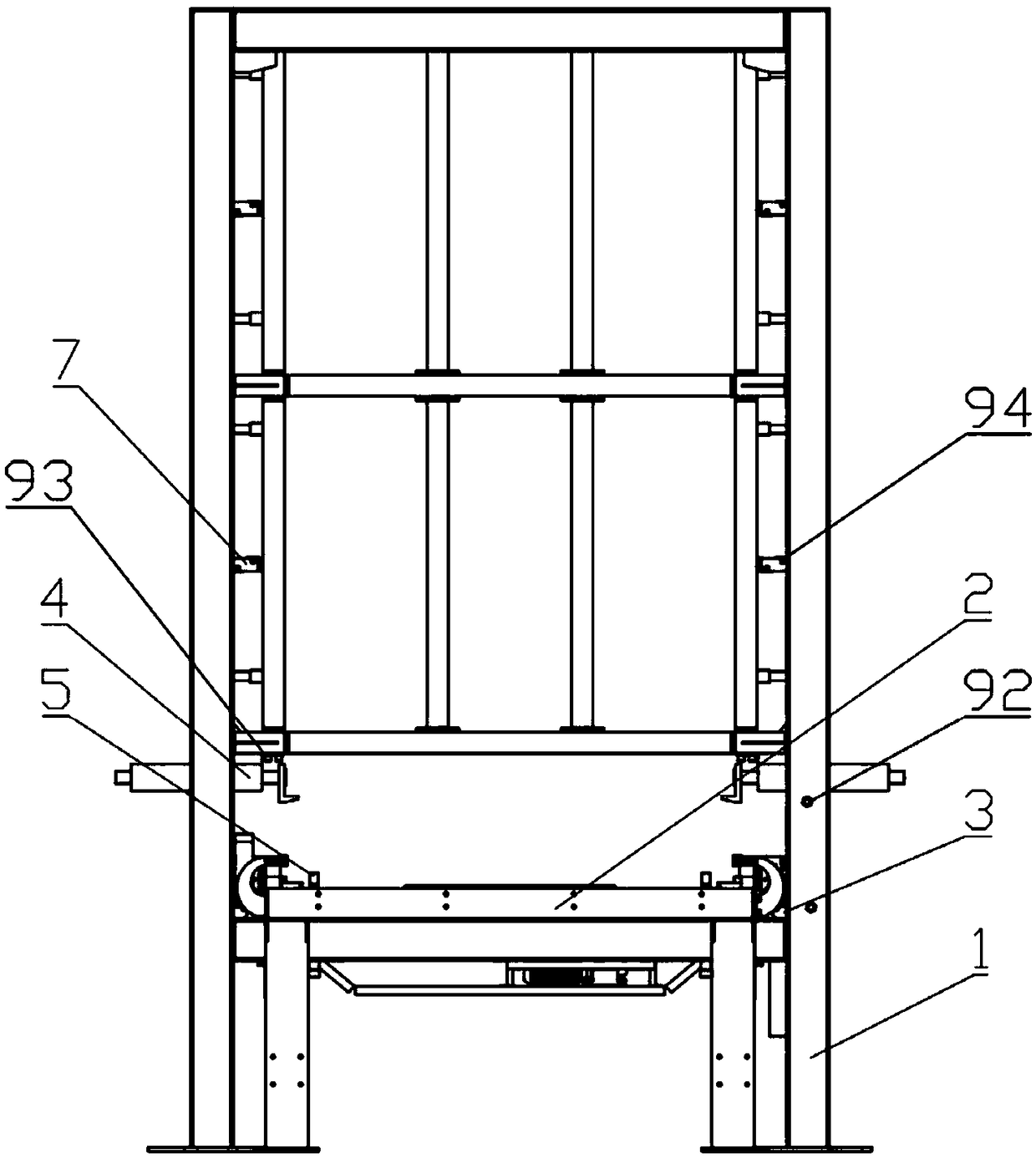

[0085] Such as Figure 1 to Figure 4 As shown, a low-level palletizing / depalletizing equipment for fermentation trays of the present invention is mainly composed of a frame 1, a pallet conveying device 2, a pallet lifting device 3, and a pallet horizontal supporting device 4. The pallet conveying device 2 , the pallet lifting device 3 and the pallet horizontal holding device 4 are installed on the frame 1 . The pallet conveying device 2 is installed below the pallet lifting device 3 and the pallet horizontal holding device 4 . The tray stacking horizontal holding device 4 is located above the left and right sides of the tray conveying device 2 . The pallet lifting device 3 is located below the pallet horizontal holding device 4 .

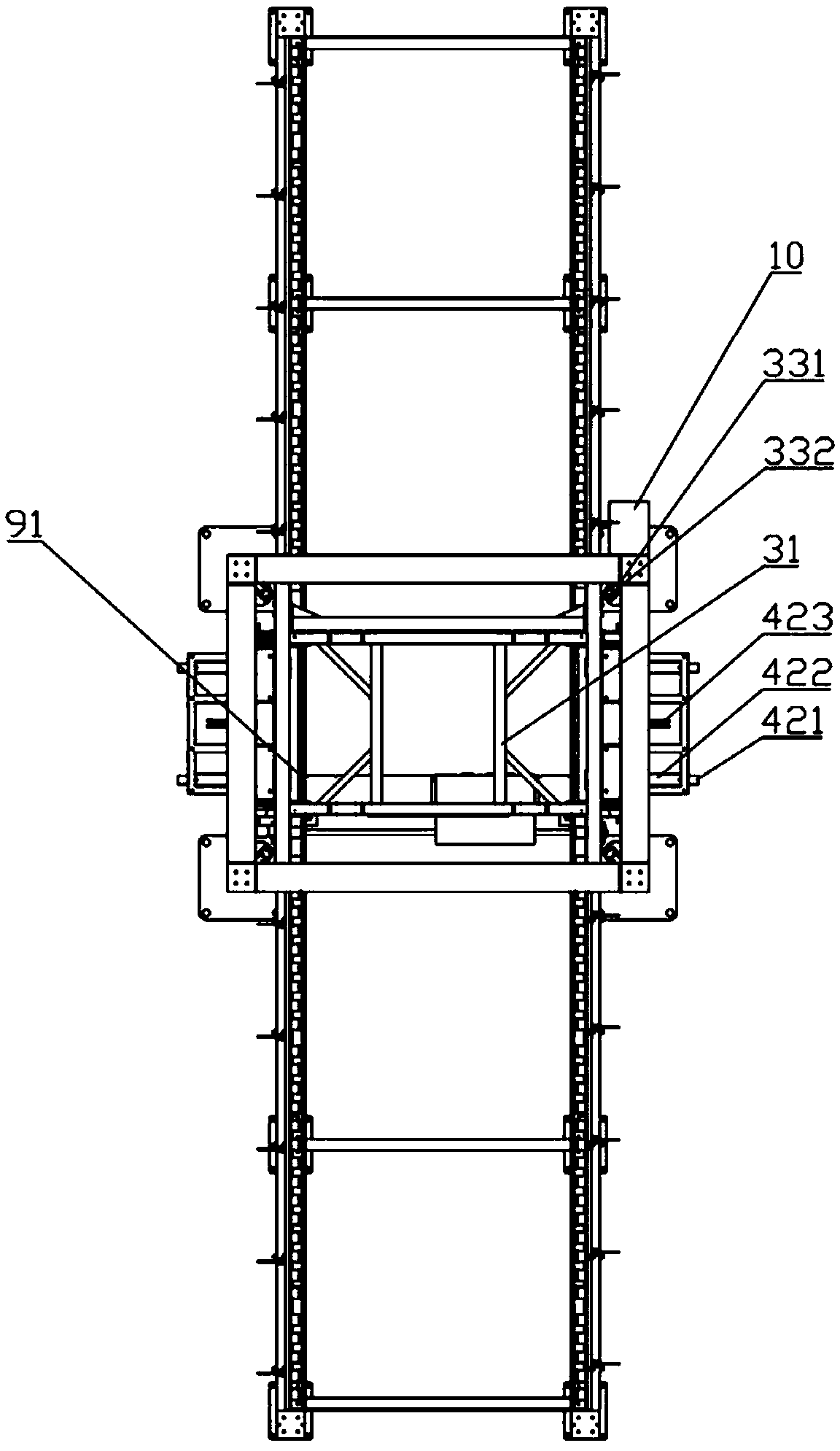

[0086] Such as Figure 4 As shown, the pallet lifting device 3 includes a lifting platform 31 , a platform lifting mechanism 32 , and a platform lifting and guiding mechanism 33 . The platform lifting mechanism 32 is installed on the frame 1 . ...

Embodiment 2

[0097] Such as Figure 5 As shown, the second embodiment of the low-position stacking / depalletizing equipment for fermentation trays of the present invention is very similar to the first embodiment, the only difference is:

[0098] The lifting platform 31 is installed below the platform lifting mechanism 32 . The lifting hydraulic cylinder 321 of the platform lifting mechanism 32 is connected and installed on the frame 1 above the lifting platform 31 through its tailstock, and the piston rod of the lifting hydraulic cylinder 321 is hinged on the lifting platform 31 through a rotatable joint.

Embodiment 3

[0100] Such as Figure 6 As shown, the third embodiment of the low-level stacking / depalletizing equipment for fermentation trays of the present invention is very similar to the second embodiment and the first embodiment, the only difference is:

[0101] Platform elevating mechanism 32 is to connect and be installed on the braking deceleration motor 322, sprocket shaft 323, sprocket wheel 324, chain 325 and counterweight 326 installed on lifting platform 31 top. The brake deceleration motor 322 and the sprocket shaft 323 are installed on the top of the frame 1 . The sprocket shaft 323 is in transmission connection with the brake reduction motor 322 . The sprocket 324 is installed on the sprocket shaft 323 . The chain 325 is wound on the sprocket 324 . One end of the sprocket 324 is connected to the counterweight 326 , and the other end of the sprocket 324 is connected to the lifting platform 31 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com