Carbon fiber concrete for construction cold joints and preparation method of carbon fiber concrete

A technology of carbon fiber concrete and carbon fiber, which is applied in the field of carbon fiber concrete for construction of cold joints and its preparation, can solve the problems of cracks in concrete, insufficient tensile strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

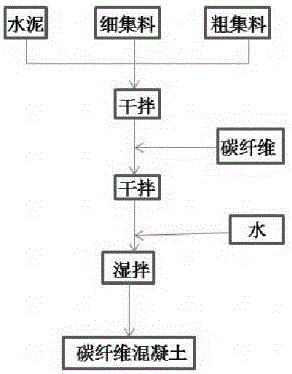

Image

Examples

Embodiment 1-3

[0036] The typical material proportion that embodiment 1-3 adopts is as follows:

[0037] Example

Carbon fiber volume ratio

water (kg / m 3 )

Cement (kg / m 3 )

Sand (kg / m 3 )

Stone (kg / m 3 )

sand rate

1

0.5

0.50%

160

320

727

1185

38%

2

0.5

0.70%

160

320

727

1185

38%

3

0.5

1.0%

160

320

727

1185

38%

[0038] Above-mentioned embodiment 1-3 adopts following steps to prepare:

[0039] Step 1. Stirring. Put the weighed sand, cement, and stones into the mixing cylinder for dry mixing, then evenly sprinkle the carbon fiber on the surface of the mixing material, and then mix it several times until the carbon fiber is uniform in the whole material. Distribute without clumping, then add water for wet mixing.

[0040]Step 2: pouring the test piece, put the lightweight aggregate concrete into the test piece mold at one time, use a spatula to sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com