Molten iron desulphurization device and method

The technology of molten iron desulfurization and molten iron tank is applied in the field of converter steelmaking, which can solve the problems of large iron loss, low unit consumption cost of desulfurizing agent, large temperature drop of molten iron, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

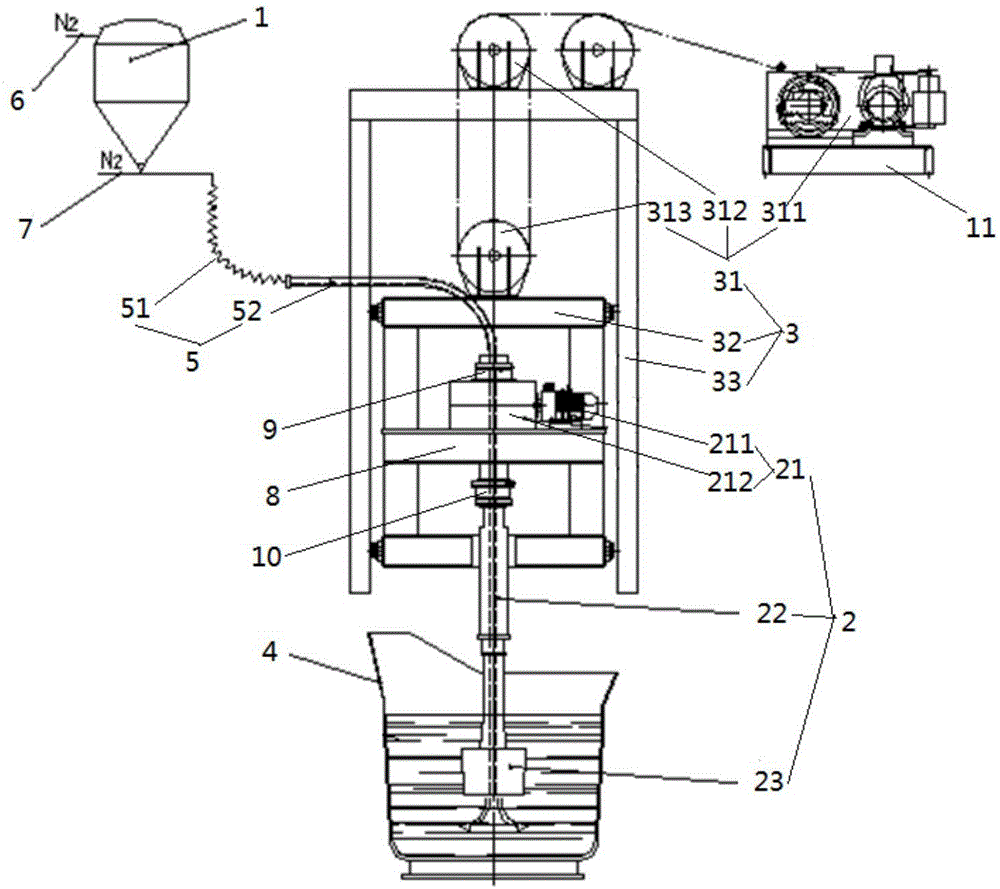

[0044] This embodiment provides a molten iron desulfurization device, including a blowing tank 1 , a stirring device 2 , a lifting device 3 , and a molten iron tank 4 . The top of the blowing tank 1 is provided with a main air pipe 6 , and the outlet of the bottom of the spray tank 1 is provided with an auxiliary blowing air pipe 7 , and the auxiliary blowing air pipe 7 is connected to the conveying pipe 5 . Nitrogen gas is passed through the main air pipe 6 and the auxiliary blow air pipe 7, and a desulfurizing agent is stored in the blowing tank 1, and the desulfurizing agent is CaO, CaF 2 The mixture, the mass percentage of CaO is 90%, CaF 2 The mass percentage is 10%. The main air pipe 6 can be set above the desulfurizing agent in the blowing tank 1, and the main air pipe 6 inflates and pressurizes the blowing tank 1 so that the desulfurizing agent flows out from the discharge port at the bottom of the blowing tank 1, assisting the blowing of the air pipe 7 Just set it u...

Embodiment 2

[0062] This embodiment provides a molten iron desulfurization device and method. The molten iron desulfurization device is basically the same as in Embodiment 1. The method for using the above device to desulfurize molten iron includes the following steps:

[0063] 1) Transport the molten iron tank 4 to the desulfurization station for temperature measurement and sampling.

[0064] 2) The lifting drive mechanism 31 is started, the traction agitator 23 is lowered, and after reaching 250mm above the liquid level of the molten iron, the auxiliary blowing vent pipe 7 is opened to blow nitrogen, and the nitrogen is ejected from the bottom of the agitator 23. At this time, the working pressure of nitrogen is 0.4MPa, Injection volume is 20Nm 3 / h.

[0065] 3) The agitator 23 continues to descend, and when it reaches the set height (the center of the agitator blade coincides with the center of the molten iron), the main ventilation pipe 6 and the discharge port of the injection tank 1...

Embodiment 3

[0072] This embodiment provides a molten iron desulfurization device and method. The molten iron desulfurization device is basically the same as in Embodiment 1. The method for using the above device to desulfurize molten iron includes the following steps:

[0073] 1) Transport the molten iron tank 4 to the desulfurization station for temperature measurement and sampling.

[0074] 2) The lifting drive mechanism 31 is started, the traction agitator 23 is lowered, and after reaching 150 mm above the liquid level of the molten iron, the auxiliary blowing vent pipe 7 is opened to blow nitrogen, and the nitrogen is ejected from the bottom of the agitator 23. At this time, the working pressure of nitrogen is 0.5 MPa, Injection volume is 25Nm 3 / h.

[0075] 3) The agitator 23 continues to descend, and when it reaches the set height (the center of the agitator blade coincides with the center of the molten iron), the main ventilation pipe 6 and the discharge port of the injection tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com