Coaxiality measurement device and detection method for mounting of vertical shaft steel lining of hydraulic floating vertical ship lift

A technology of vertical ship lift and coaxiality measurement, which is applied to mechanical measuring devices, vertical lifting ship machinery, measuring devices, etc., can solve the problems of low precision and large workload, and achieves accelerated construction progress, simple operation, The effect of reducing the inspection workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

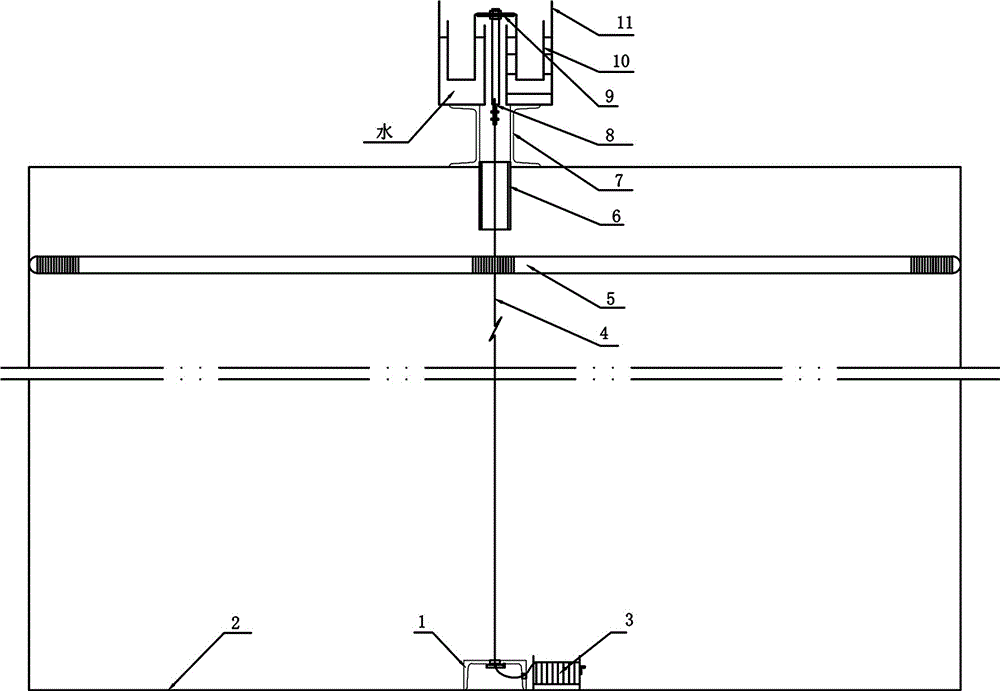

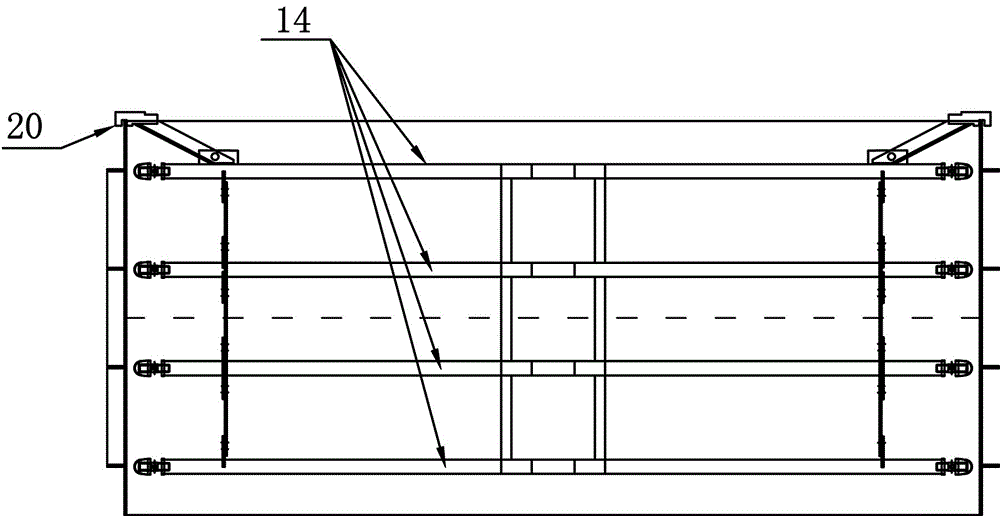

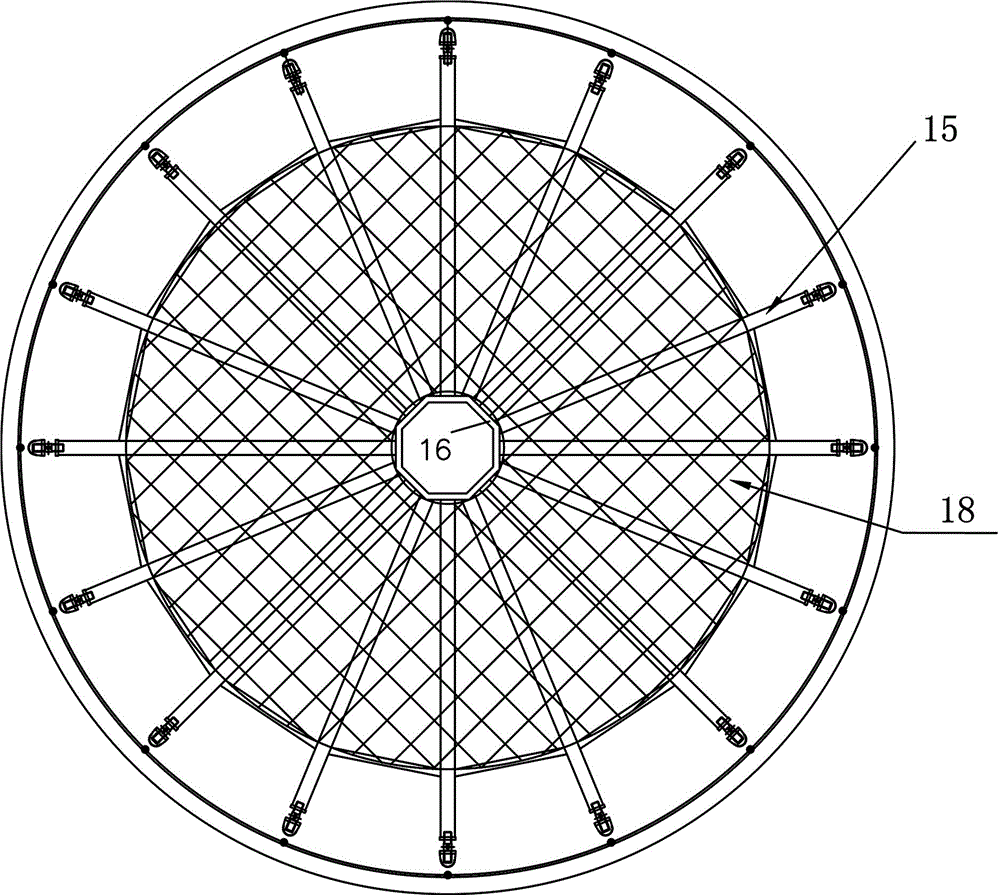

[0054] Such as Figure 1-3 Shown, a kind of coaxiality measuring device for the steel lining installation of the shaft of the hydraulic floating vertical ship lift, which includes a measuring instrument and a detection operation platform;

[0055] In the measuring instrument, the fixed orifice plate 1 is installed on the design center of the steel substrate plate 2, and a positioning hole is opened in the center of the fixed orifice plate 1, and the center reference line 4 wound on the reel 3 passes through the fixing hole from bottom to top After the positioning hole on the plate 1 is fixedly connected with the connecting rod 8 of the buoyancy device, the connecting rod 8 is installed between the two measuring brackets 7 of the nozzle on the first shaft steel lining section 12 or the subsequent shaft steel lining section 13 to be installed. In the middle position, in the floating bucket device, the floating bucket 11 is installed on the two measuring brackets 7 and is located...

Embodiment 2

[0063] Such as Figure 4-7 Shown, a kind of coaxiality detection method adopting above-mentioned coaxiality measuring device to carry out the steel lining installation of hydraulic floating type vertical ship lift shaft, the method comprises the following steps:

[0064] Step 1: Arrangement of measuring instruments on the steel lining section 12 of the first shaft: before installing the steel lining section 12 of the first shaft, weld the fixed orifice plate 1 on the steel substrate plate 2, and measure and release at the center of the fixed orifice plate 1 with a total station Install the center point, drill a hole at the installation center point, place the reel 3 under the fixed orifice plate 1, hoist the first shaft steel lining section 12 with the detection operation platform installed on the steel substrate plate 2, and place the steel lining section 12 on the first shaft steel plate Two measuring brackets 7 are placed on the upper nozzle of the liner 12, and a floating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com