A mechanized rapid construction method for prefabricated assembled underground corridors

A construction method and prefabricated assembly technology, which is applied to artificial islands, water conservancy projects, underwater structures, etc., can solve problems such as the lack of prefabricated assembled underground corridor construction methods, so as to quickly adapt to changes in ground environmental conditions and reduce engineering costs. Cost, simple and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

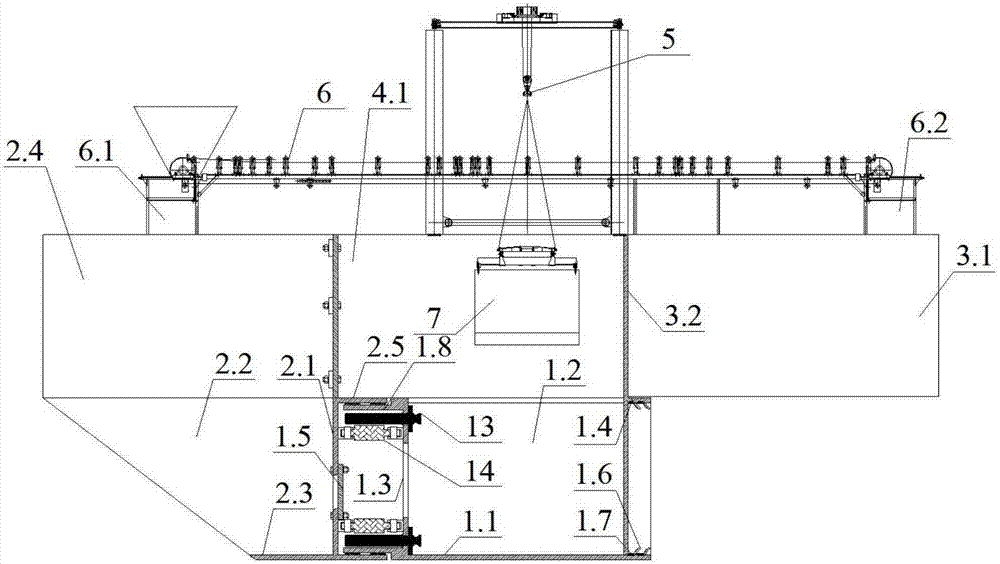

[0071] Embodiment 1: When the corridor construction area is all pavement excavable, its construction method comprises the following steps:

[0072] 1) Excavate a long foundation pit at the beginning of the corridor. The excavation of the foundation pit may collapse due to the soil layer, so it is necessary to support the foundation pit. Insert steel sheet piles to reinforce the foundation pit to avoid the collapse of the foundation pit.

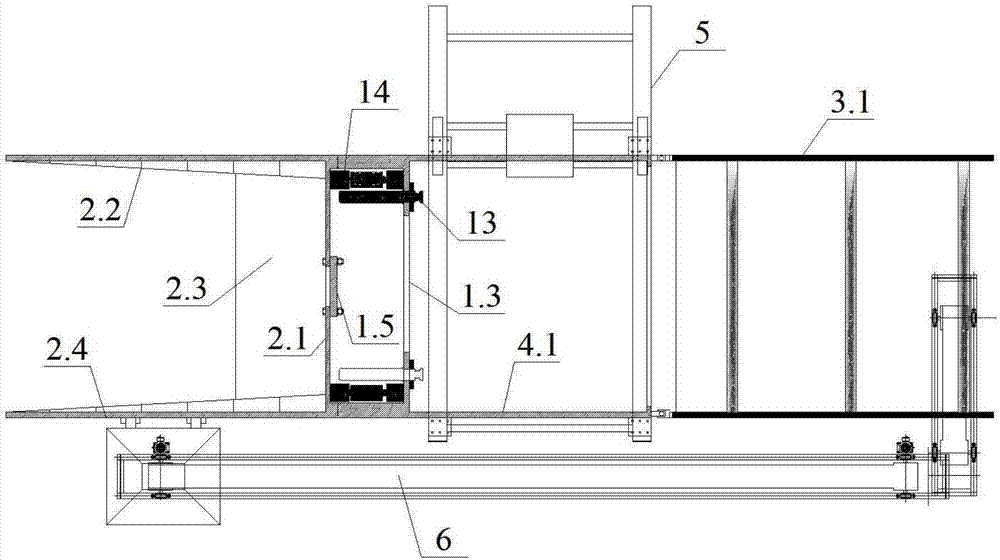

[0073] For specific supporting structures, see Figure 6 A row of 8 horizontal steel sheet piles is inserted along the horizontal direction of the corridor (the horizontal direction in this embodiment refers to the extension direction perpendicular to the corridor, and the longitudinal direction refers to the extension direction along the corridor) in the elongated foundation pit. For the soil mass at the starting end of the corridor, a row of longitudinal steel sheet piles 9 is respectively inserted along the longitudinal direction of the c...

Embodiment 2

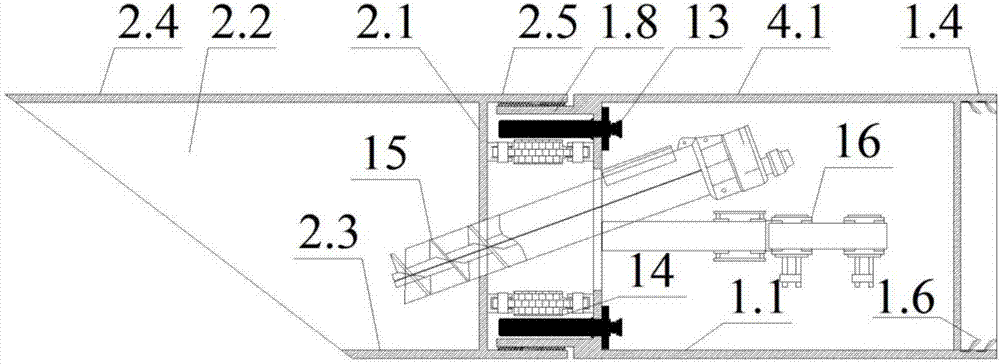

[0091] Embodiment 2: In the construction area of the corridor, the open-cut section of the road surface that can be excavated is constructed first, and then when passing through the area of the road surface that cannot be excavated, underground excavation construction is required. The construction steps are as follows:

[0092] 1), the construction of open cut section is the same as the construction method recorded in embodiment 1.

[0093] 2) When the assembly cabin runs to the underground excavation section, it is necessary to adjust the assembly cabin 1 of the open excavation mode to the assembly cabin 1 of the underground excavation mode. The adjustment method is: use the gantry crane 5 to lift the screw conveyor 15 and the segment assembly machine 16 to the assembly cabin 1, remove the sealing door 1.5 on the second cross plate 2.1, install the screw conveyor 15 on the second cross plate 2.1, and install the segment assembly machine 16 on the first cross plate 1.3; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com