Friction-mild steel composite damper

A composite, damper technology, applied in the field of dampers, can solve problems such as difficulty in determining the sliding friction force, and achieve the effect of protecting the safety of the structure, reducing the dynamic response and the accumulation of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

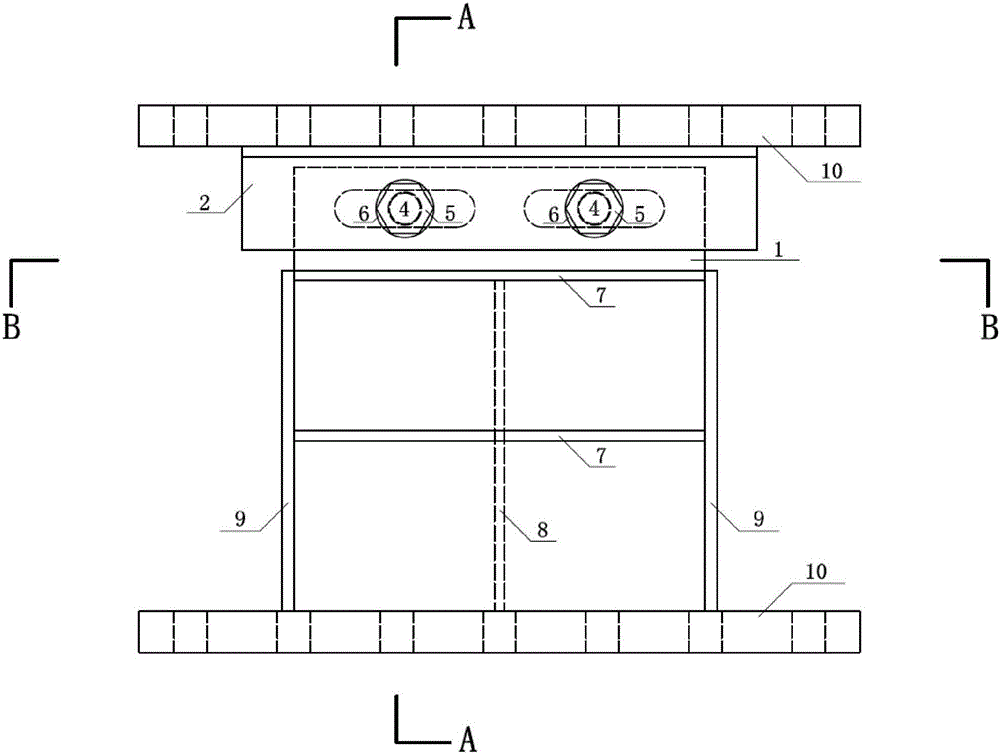

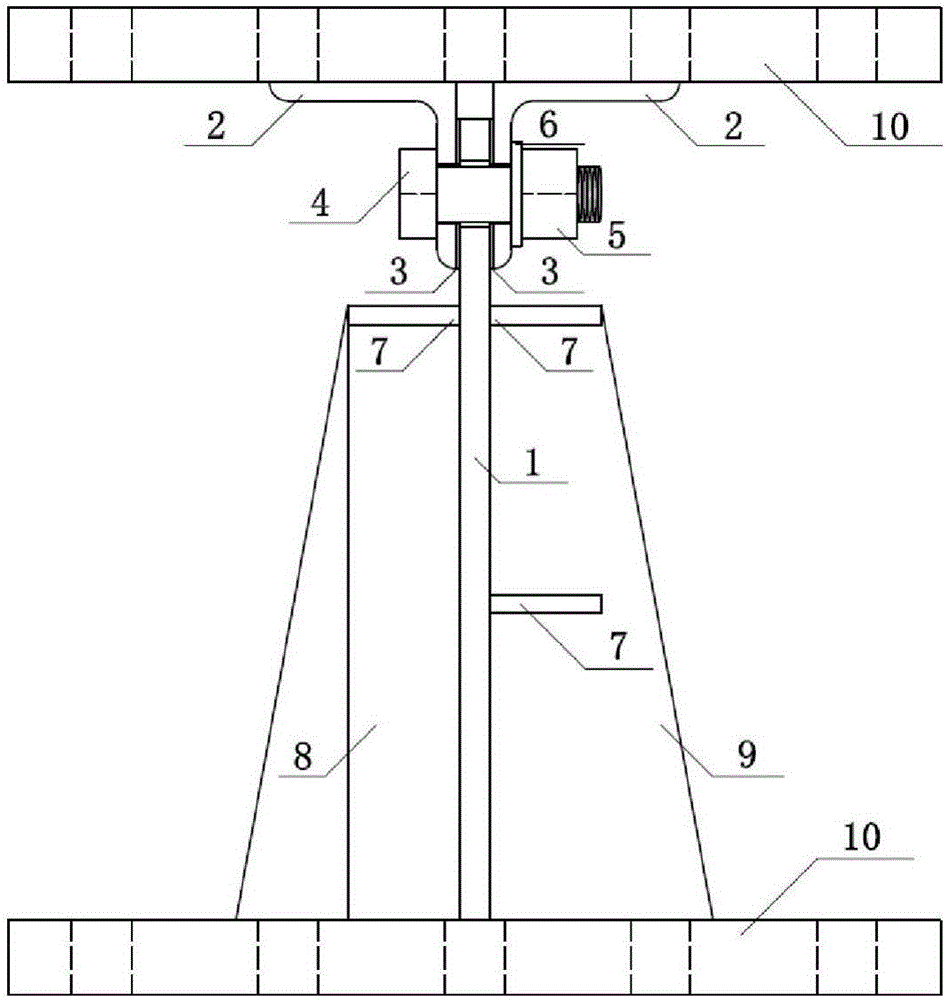

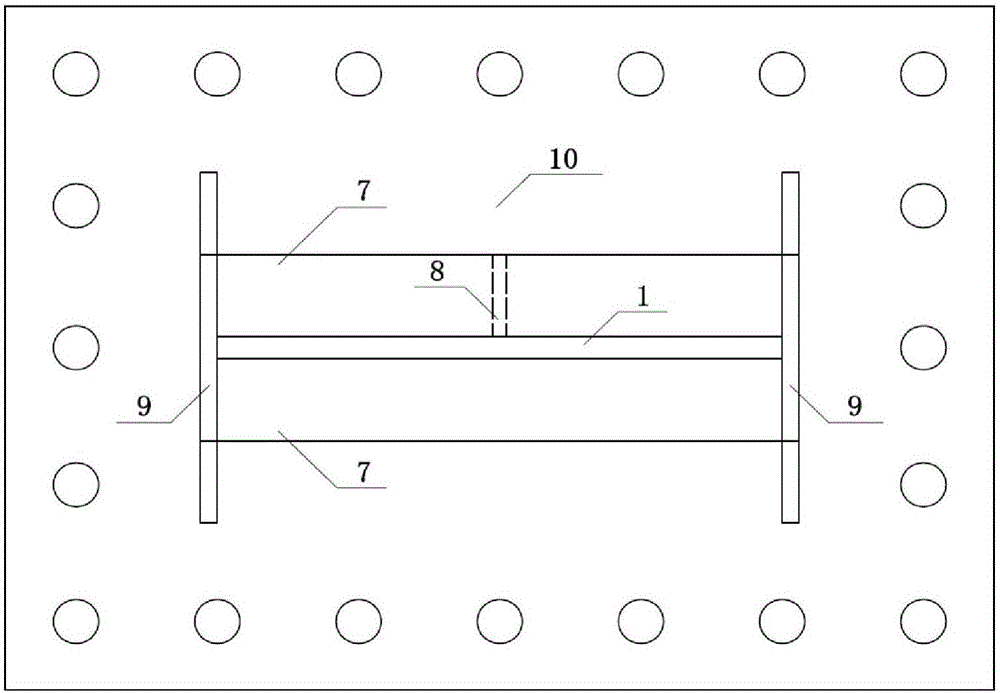

[0038] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes a shearing energy-dissipating steel plate 1, an angle steel 2, and a friction plate 3. An angle steel 2 is installed on both sides of one end of the shearing energy-dissipating steel plate 1, and one side of the vertical direction of the angle steel 2 is connected to the shearing energy-dissipating steel plate 1. A friction plate 3 is installed between them, and the shearing energy-dissipating steel plate 1, the angle steel 2 and the friction plate 3 are connected and pre-tightened by the connection adjustment mechanism, thereby changing the sliding friction between the friction plate 3 and the shearing energy-dissipating steel plate 1 force.

[0039] In this embodiment, the connection adjustment mechanism includes a bolt 4, a nut 5, and a washer 6. For example, a high-strength bolt connection pair is formed by using a large hexagon head bolt 4, a large hexagon nut 5, and a washer 6, and ...

Embodiment 2

[0055] Such as Figure 10 As shown, in this embodiment, two groove-shaped holes are added on the shear energy-dissipating steel plate 1, and at the same time, a row of mounting holes is added on the angle steel 2 and the friction plate 3. Correspondingly, the gap between the three It is connected together by four sets of high-strength bolts.

[0056] Other parts are identical with embodiment 1.

[0057] The working principle of embodiment 2 is basically the same as that of embodiment 1. The difference is that the number of friction parts in embodiment 2 is increased compared with that of embodiment 1. Under the same loading conditions, the sliding friction force provided by embodiment 2 is theoretically higher than that of the actual embodiment. Example 1 is doubled. Therefore, Example 2 has stronger friction energy dissipation capacity than Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com