Device for preventing gland housing in feed pump steam turbine balancing piston from deformation

A technology of feed water pump steam turbine and balancing piston, which is applied in mechanical equipment, engine components, transportation and packaging, etc., can solve the problems of inability to reassemble the deformation, complicated heat treatment process, deformation of the steam seal body, etc., so as to save the construction period and guarantee the maintenance cost. and construction period requirements, the effect of saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

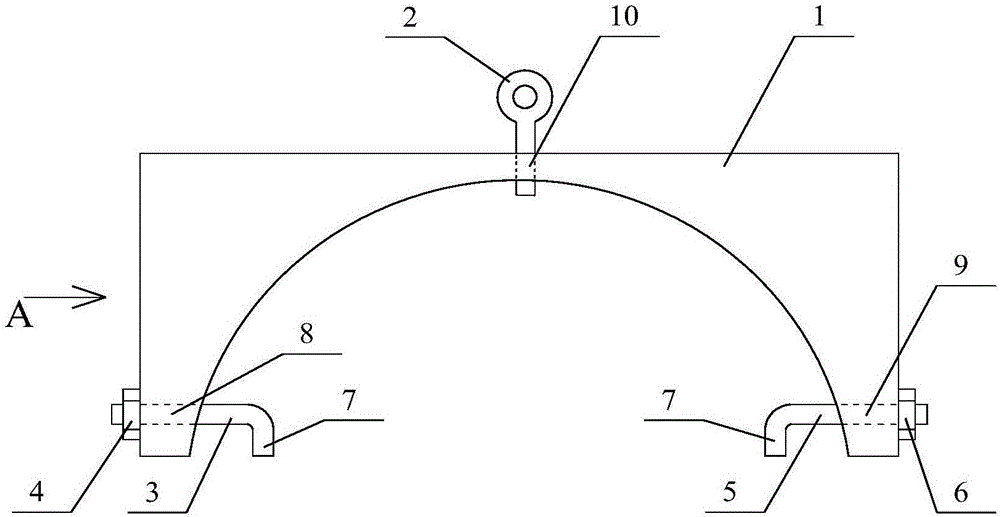

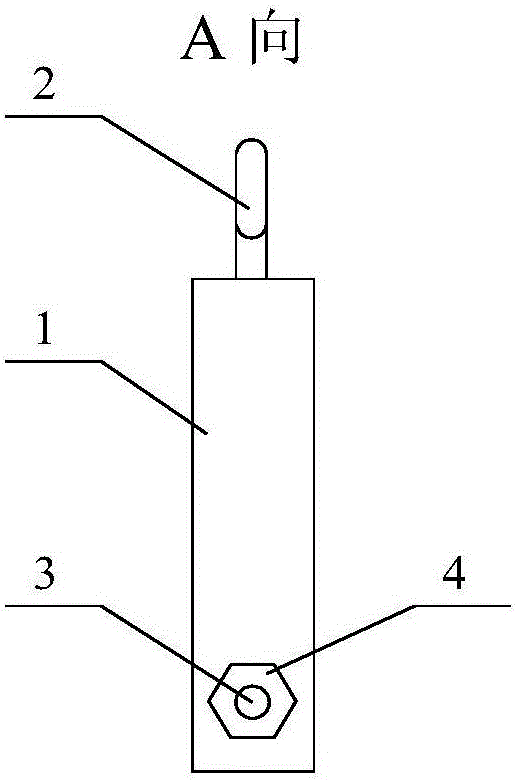

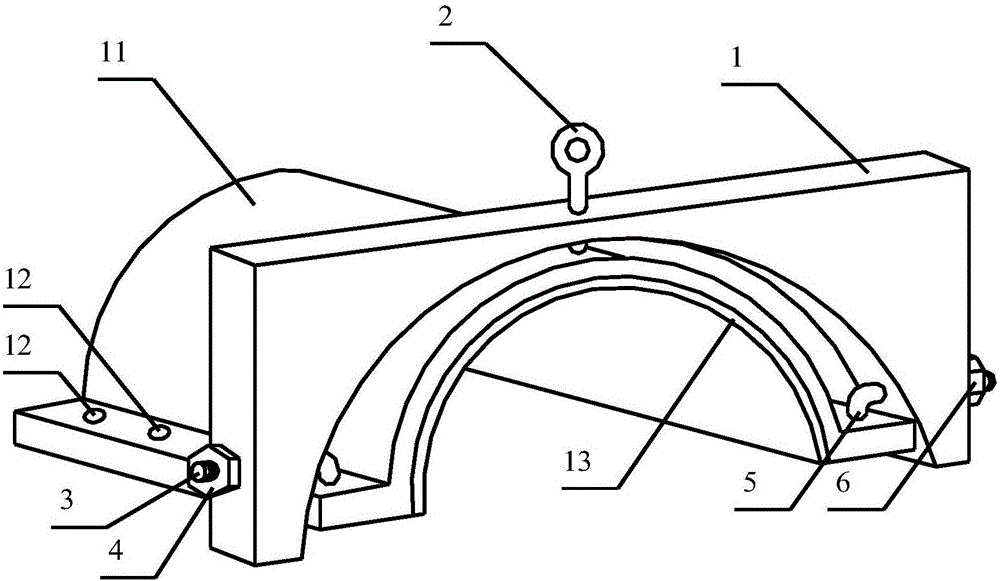

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

[0013] like Figure 1 ~ Figure 3 As shown, a device for preventing the deformation of the steam seal body in the balance piston of the feedwater pump steam turbine involved in this embodiment includes: a bracket 1, a lifting ring 2, a first bolt 3, a first nut 4, a second bolt 5, a second Nut 6 and hook 7, the outside of described support 1 is rectangular structure, the inside of support 1 is arc-shaped structure, and the upper middle position of support 1 is provided with threaded hole 10, and suspension ring 2 is screwed with threaded hole 10 on the support 1 , the lower part of the left side of the bracket 1 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com