A Centrifugal Pump Remaining Life Prediction Method

A life prediction and prediction method technology, which is applied in pump control, non-variable pumps, machines/engines, etc., can solve problems such as centrifugal pumps that do not have the prediction function, and achieve the effect of improving reliability and accurate prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be further described below.

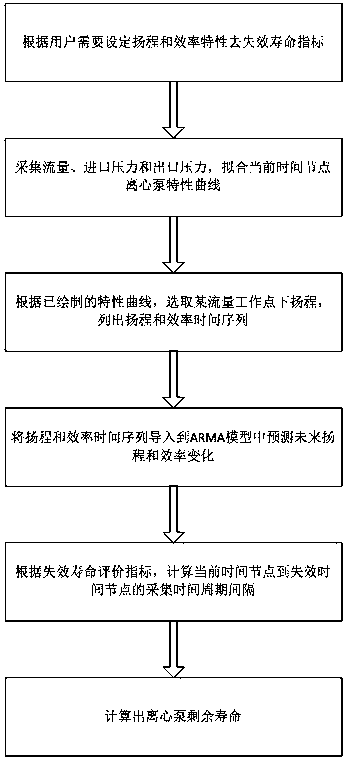

[0038] A method for predicting the remaining life of a centrifugal pump is implemented, including a method for evaluating the failure life index of a centrifugal pump, a method for predicting the remaining life of a centrifugal pump in ARMA time series, and a method for arranging monitoring points for predicting the remaining life of a centrifugal pump.

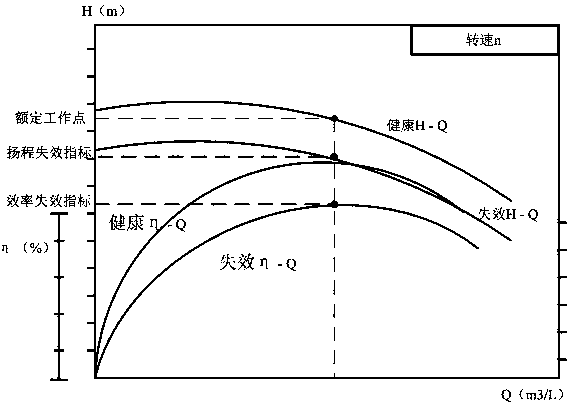

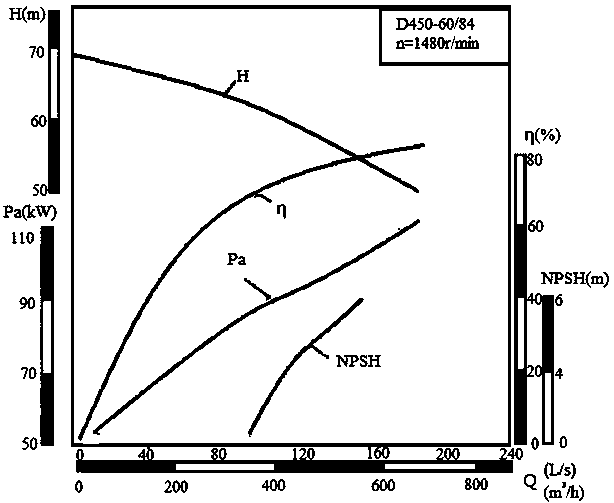

[0039] The method for evaluating the failure life index of the centrifugal pump includes the flow-head (H-Q) characteristic curve and the efficiency-flow (η-Q) characteristic curve of the centrifugal pump, and determines the deviation of the two characteristic curves of the centrifugal pump at their working points, and determines the Whether the centrifugal pump is malfunctioning or failing.

[0040] The working point is one of the rated working point of the centrifugal pump or the working point of any flow rate.

[0041] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com