Fan device and machining method

A processing method and fan technology, applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve the problem of difficult to ensure the bonding strength, concentricity and It is difficult to guarantee the balance and the bonding strength, etc., so as to save the casing material, improve the service life and achieve the effect of good concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

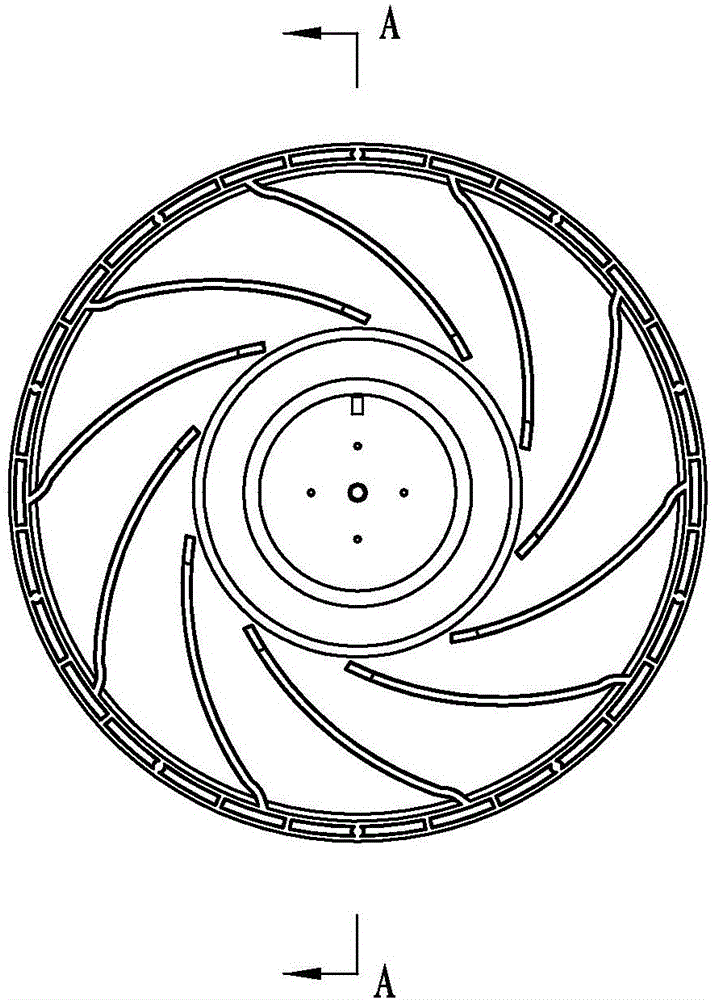

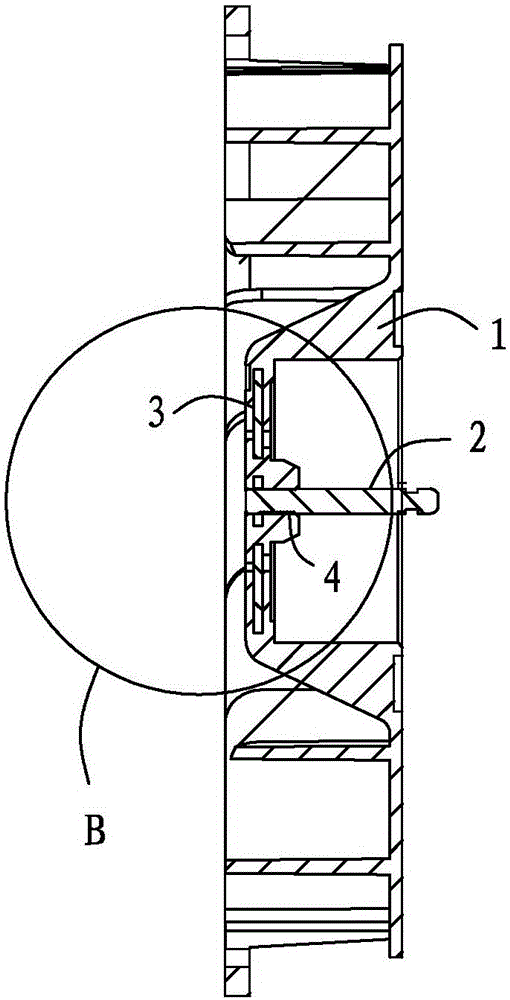

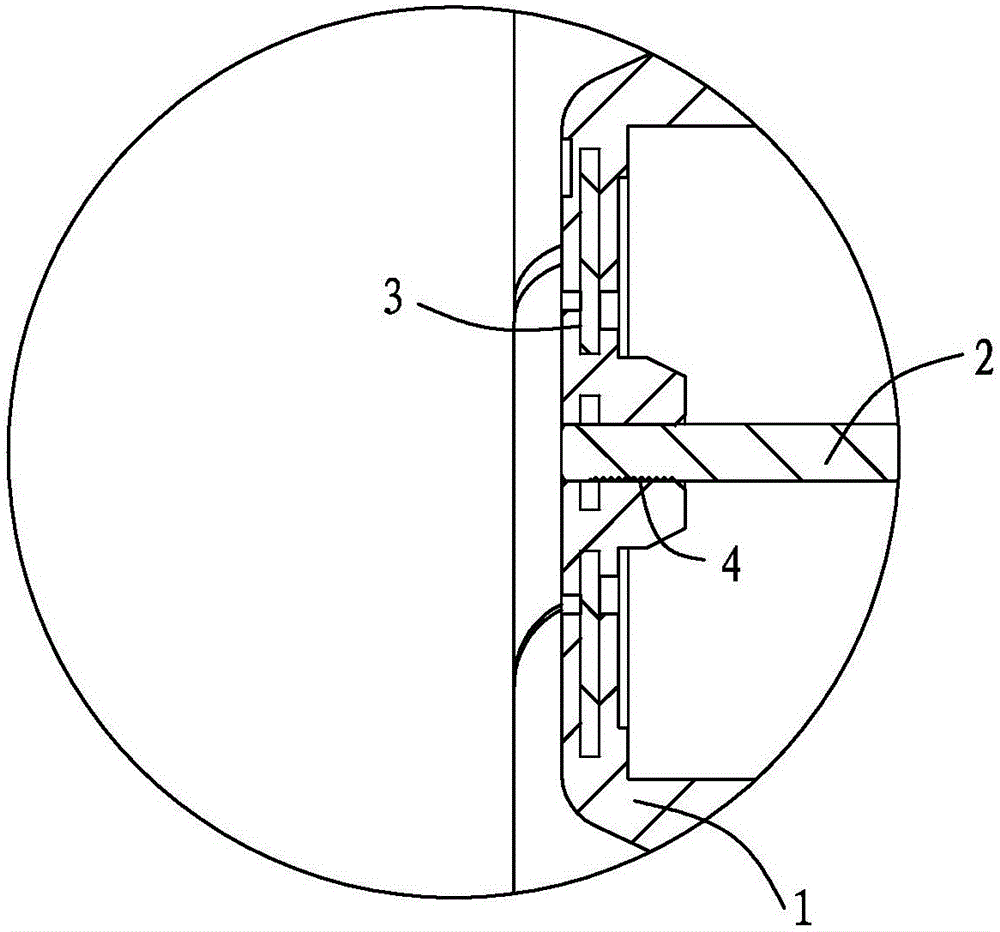

[0021] refer to figure 1 , figure 2 , image 3 and Figure 4 : Fan device, including fan blade 1, rotating shaft 2 and insert 3, one end of rotating shaft 2 is provided with knurling 4, fan blade 1 is sleeved on one end of rotating shaft 2, insert 3 is sleeved on the outside of rotating shaft 2, and embedded in Inside the fan blade 1. The knurling 4 at one end of the rotating shaft 2 has a pineapple-like pattern, which increases the tightness of the combination of the fan blade 1 and the injection molding at one end of the rotating shaft 2, and ensures the stability of the connection between the two.

[0022] Wherein, the fan blade 1 is an injection molded part, and the thickness of the insert 3 is 1-1.5 mm, preferably 1 mm.

[0023] The insert 3 is circular, and a round hole is arranged in the middle of the insert 3 , and the inner diameter of the roun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com