Petroleum pipe fitting allowing wiring to be carried out easily

A technology for oil pipes and cables, applied in the direction of pipes/pipe joints/fittings, pipe supports, electrical components, etc., can solve the problems of complicated operation, low wiring efficiency, built-in wiring structure, etc., to achieve simple and efficient wiring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings.

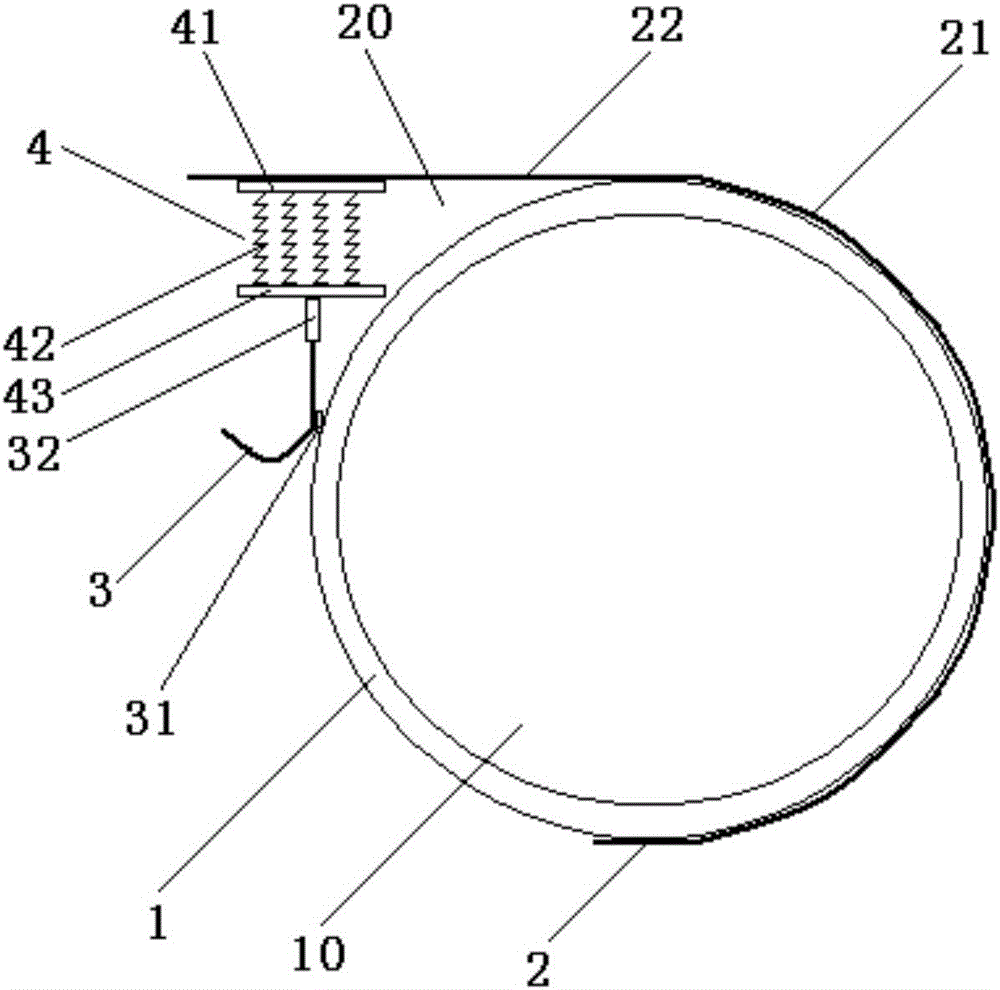

[0017] like figure 1 An easy-to-route oil pipe fitting shown includes a pipe body 1 and a cable fastener 2, the pipe body 1 has a medium channel 10 for oil circulation, and the cable fastener 2 comprises a snap body connected in sequence 21 and the cable suspension plate 22; the buckle body 21 is detachably mounted horizontally and is wrapped on the outer wall arc of the pipe body 1, the cable suspension plate 22 horizontally extends on the top of the buckle body 21, A wiring space 20 is formed between the bottom surface of the cable suspension plate 22 and the pipe body 1 .

[0018] The bottom surface of the cable suspension plate 22 is provided with a wire hook 3 located in the wiring space 20 for hooking the wiring cable, which is used for hooking the laid cable and can stabilize the cable.

[0019] The wire hook 3 is suspended from the bottom surface of the cable s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com