Industrial waste heat and solar energy combined cross-season heat accumulation and regional heat supply system

A technology for industrial waste heat and district heating, which is applied in the field of cross-seasonal heat storage and district heating systems, can solve the problems of ineffective utilization of industrial waste heat, idle heat of equipment, waste of energy grade, etc., to optimize the process of heat extraction and release, The effect of saving primary energy and improving temperature grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

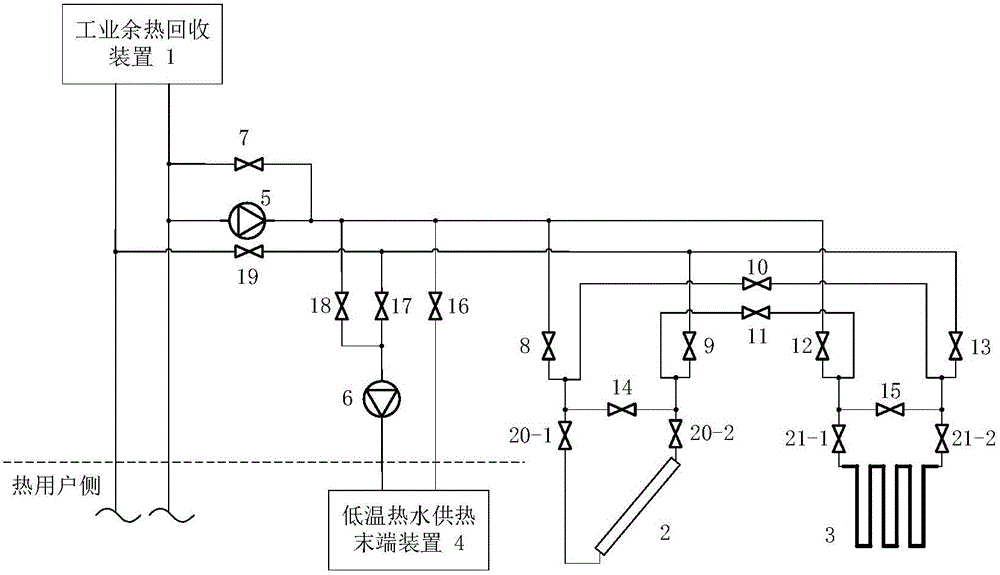

Embodiment 1

[0035] The structure of Example 1 of the cross-season heat storage / district heating system combined with industrial waste heat and solar energy of the present invention is as follows figure 1 As shown, the system consists of industrial waste heat recovery device 1, solar collector 2, buried pipe heat exchanger 3, low-temperature hot water heating terminal device 4, circulation pump 5, circulation pump 6, valves 7-21, and connecting pipelines , four sets of temperature sensors (not shown in the figure), a controller for controlling the opening and closing of the valve, and an electric actuator (not shown in the figure); wherein, the water outlet of the industrial waste heat recovery device 1 is connected to the parallel The valve 7 is connected to one end of the circulation pump 5, and the other end of the parallel valve 7 and the circulation pump 5 is connected to one end of the valve 18, valve 16, valve 8 and valve 12 in turn; the water inlet of the industrial waste heat recov...

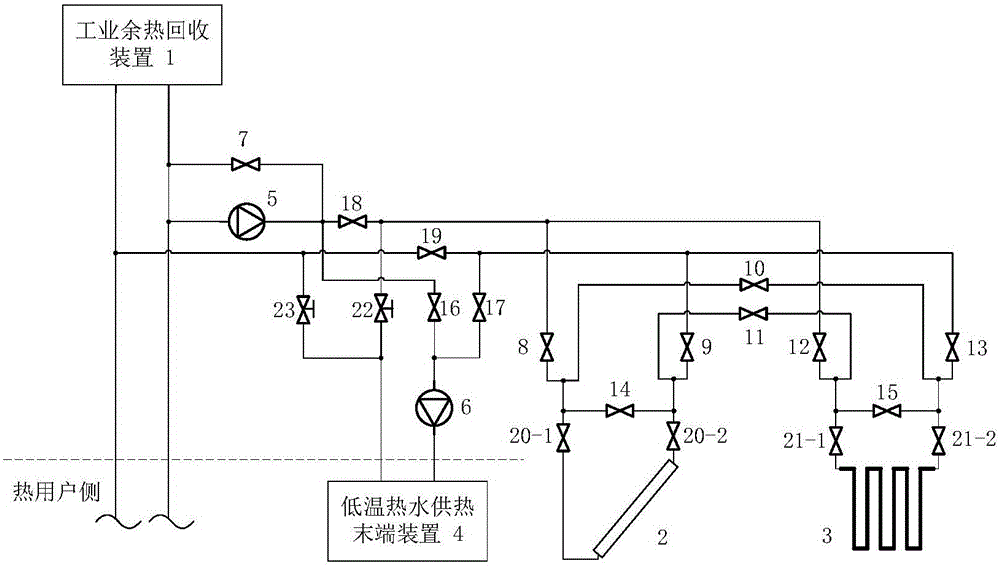

Embodiment 2

[0039] The structure of embodiment 2 of the inter-season heat storage / district heating system combined with industrial waste heat and solar energy of the present invention is as follows figure 2 As shown, the system consists of industrial waste heat recovery device 1, solar collector 2, buried pipe heat exchanger 3, low-temperature hot water heating terminal device 4, circulation pump 5, circulation pump 6, valves 7-23, and connecting pipelines And four sets of temperature sensors (not shown in the figure), a controller for controlling the opening and closing of valves and an electric actuator (not shown in the figure), wherein, the water outlet of industrial waste heat recovery device 1 is connected to the parallel valve through the connecting pipeline 7 is connected to one port of the circulation pump 5, and the parallel valve 7 and the other port of the circulation pump 5 are connected to one end of the valve 18, and at the same time connected to one end of the valve 16, an...

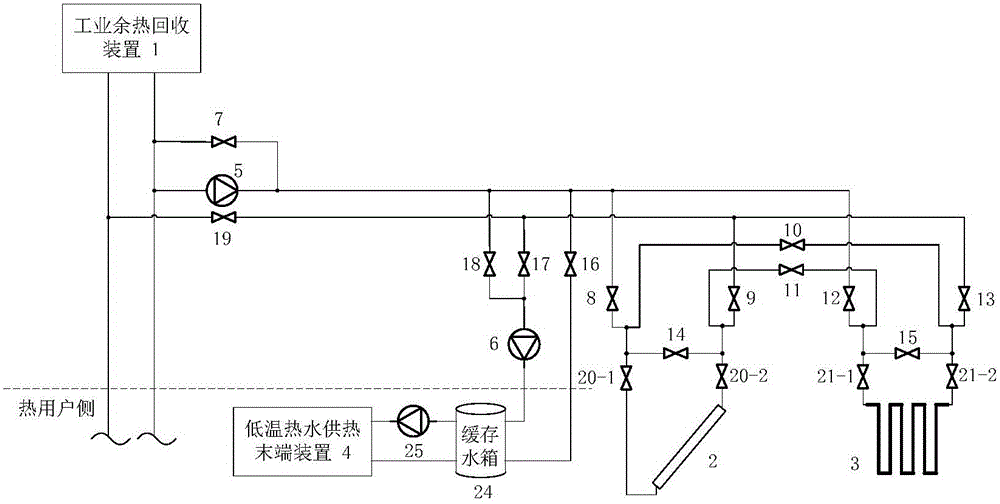

Embodiment 3

[0043] The structure of embodiment 3 of the inter-season heat storage / district heating system combined with industrial waste heat and solar energy of the present invention is as follows image 3 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, on the basis of the components of Embodiment 1, it also includes a buffer water tank 24 and a circulation pump 25, wherein the first buffer water tank (24) The water outlet and the second water inlet are respectively connected with the water inlet and the water outlet of the low-temperature hot water heating terminal device (4), the first water inlet of the buffer water tank (24) is connected with the second circulation pump (6), and the second water outlet Connected with the tenth valve (16), the third circulation pump (25) is connected between the first water outlet of the buffer water tank (24) and the water inlet of the low-temperature hot water heating terminal device (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com