Vaporization bubble test apparatus with adjustable pressure and adjustable temperature

A test device and technology of vaporization bubbles, which are applied in the field of liquid vaporization process test devices to achieve the effect of good adjustability and various functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

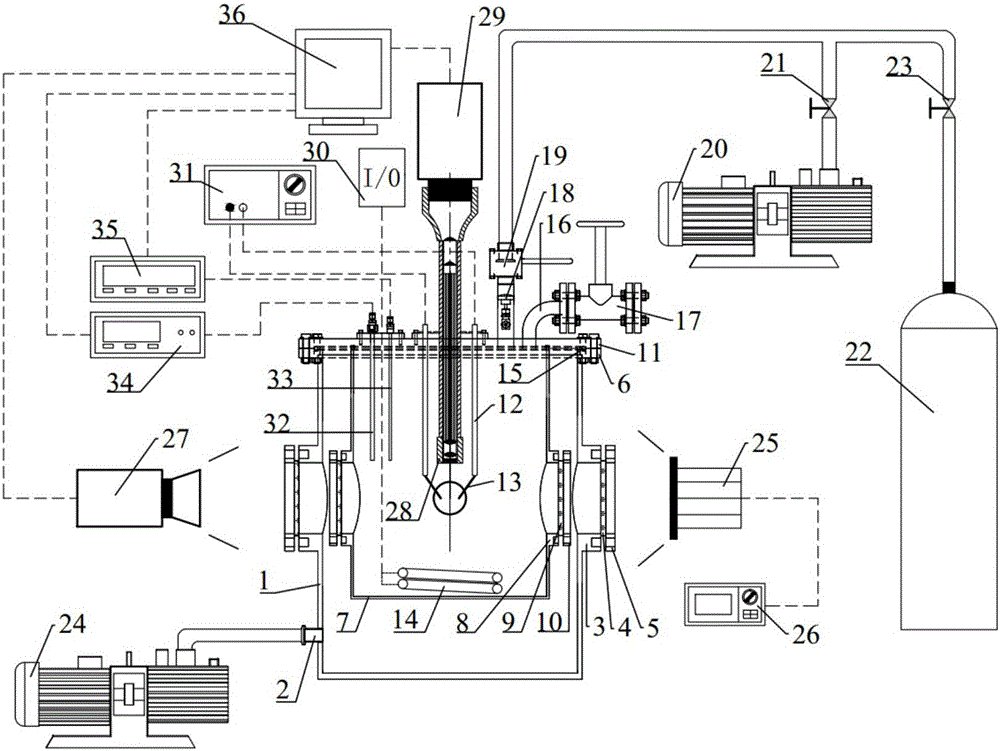

[0043] Such as figure 1 As shown, a vaporization bubble test device with adjustable pressure and temperature includes a vacuum tank part, a test tank part, auxiliary equipment parts, and a data acquisition system.

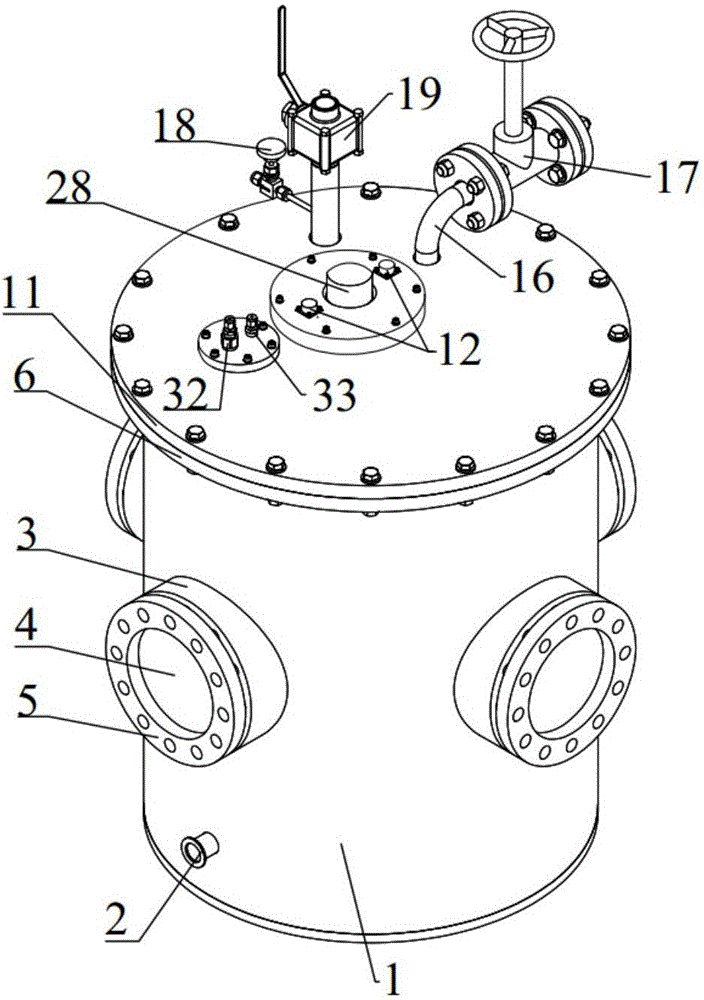

[0044] Such as figure 1 and figure 2 As shown, the vacuum tank part is used to provide a vacuum environment; including vacuum tank 1, vacuum interface 2, vacuum tank flange 3, first observation window 4, first flange 5, second flange 6, connection relationship : the vacuum tank 1 is a cylindrical tank with an open top, the diameter of the central through hole of the second flange 6 is the same as the outer diameter of the upper edge of the vacuum tank 1, and the upper edge of the vacuum tank 1 is the same as the second flange 6 The upper surface of the vacuum tank 1 is flush and fixed by welding; the side wall of the middle part of the vacuum tank 1 is provided with four circular through holes at equal intervals along the circumferential direction, and the size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com