An ultra-high pressure non-metallic core holder

A core holder, non-metallic technology, applied in the field of ultra-high pressure non-metallic core holders, can solve the problems of structural tightness and unreasonable structure, poor sealing performance, and inability to complete core CT scanning, etc., so as to reduce the service life , Reduce gas resistance, reduce the effect of pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

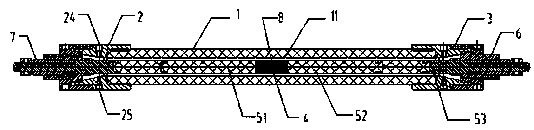

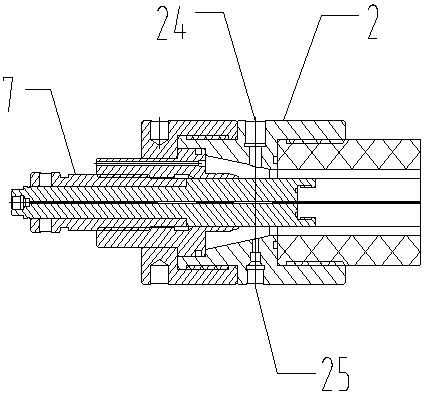

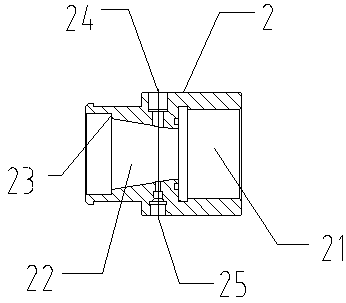

[0037] Such as Figure 1 to Figure 7 The shown ultra-high pressure non-metallic core holder includes a holder body 1 , a head 2 , a head pressure cap 3 , a core 4 , a core plug 5 , a core plug plug 6 and an adjustment pressure cap 7 .

[0038] The main body 1 of the holder is a non-metallic cylindrical structure. There is a through hole 11 for accommodating the rock core in the middle of the main body 1 of the holder. Threads are provided on the outer walls of both ends of the main body 1 of the holder; the core 4 and the core plug 5 are placed in the holder There is a ring pressure gap between the through hole 11 of the holder body 1 and the inner wall of the holder body 1, and a heat source can be used to heat the holder in a circular manner.

[0039] The head 2 has a pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com