Reverse osmosis influent SDI (silt density index) auto-testing device and control method

An automatic test device, reverse osmosis technology, applied in the direction of testing water, material inspection products, etc., can solve the problems of complex SDI test operation, inconvenient device carrying, unclear data processing, etc., to achieve convenient automatic testing, low power consumption, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

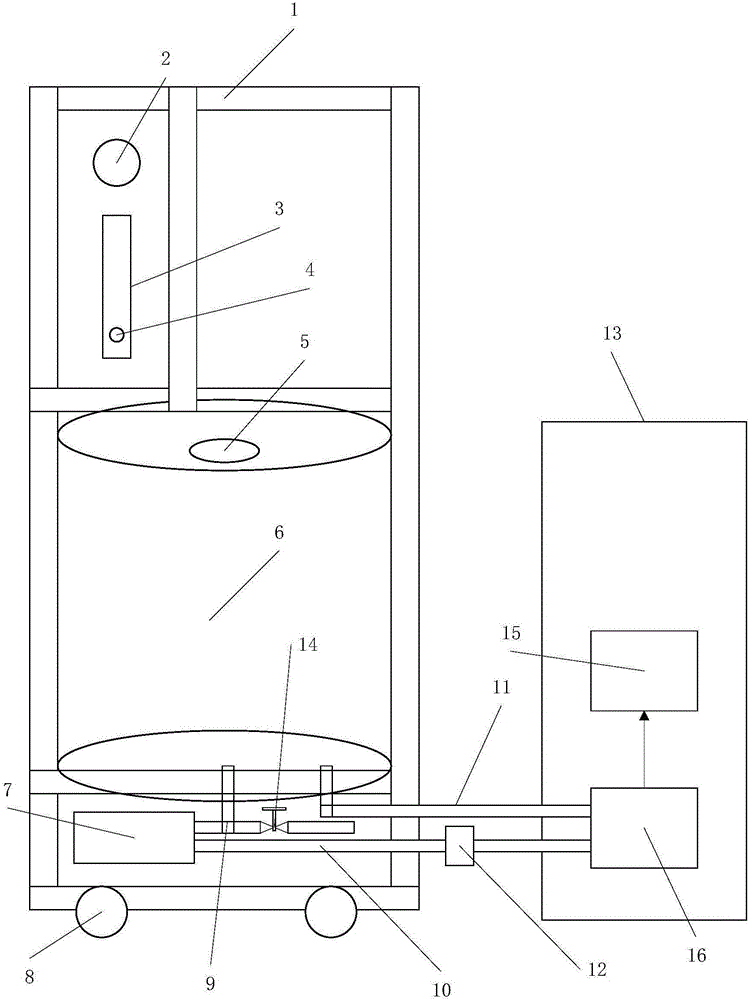

[0025] Open the bucket cover 5, pour the sampled water back into the bucket 6, operate the main control system 13, open the booster pump 7, adjust the pressure regulating valve 4, watch the pressure gauge 2, and adjust the pressure to 30psi.

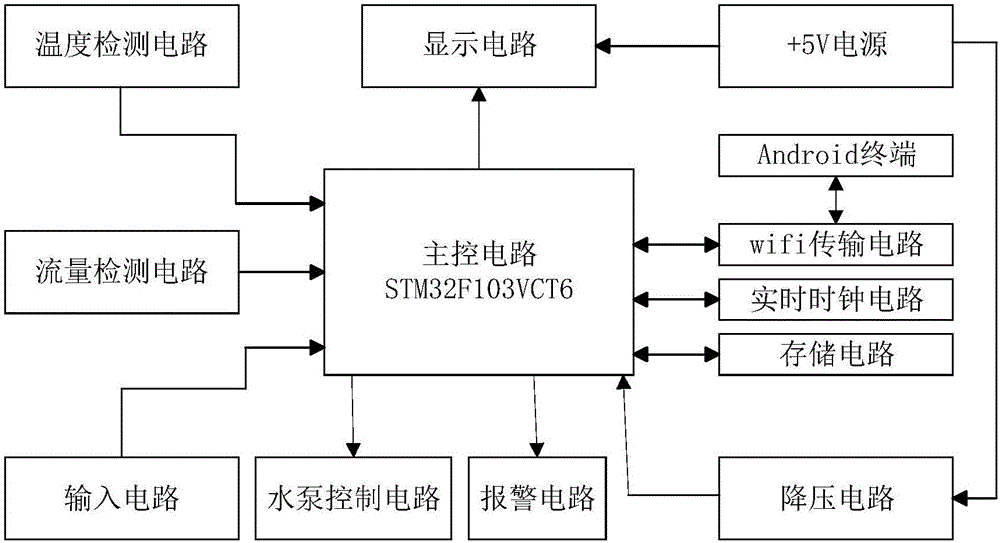

[0026] like figure 2 As shown, the system function is selected through the human-computer interaction input circuit and display circuit:

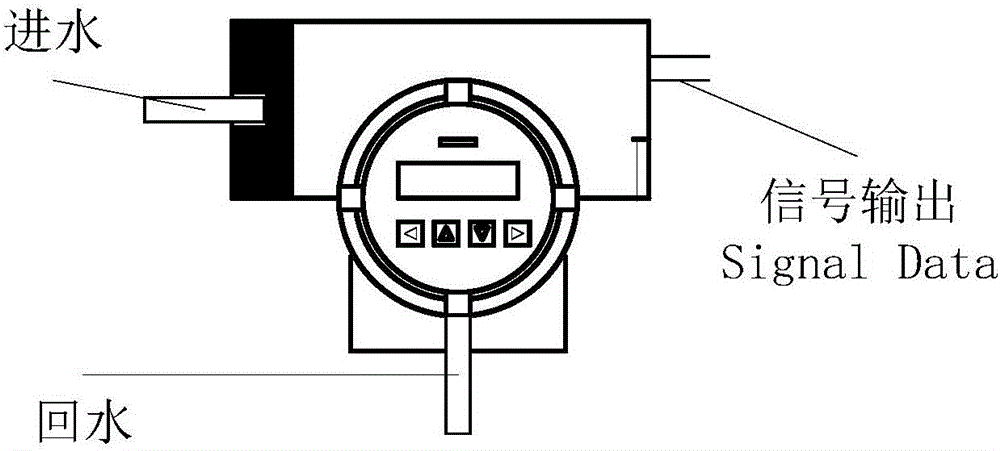

[0027] After entering the "density detection" option, the main control system 13 first collects a temperature through the temperature detection circuit, and then turns on the booster pump 7 through the water pump control circuit, and after increasing the water pressure, the raw water to be tested is transported to the microfiltration membrane through the water delivery pipe 10 Unit 12, the measured raw water flows through the electromagnetic flow sensor 16 ( image 3 As shown), the signal collected by the flow detection circuit is sent to the main control circuit STM32F103VCT6 for processing. When i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com