Improved-principle-component-tracking-based industrial process monitoring method and application

A principal component tracking, industrial process technology, applied in the field of online industrial fault detection and identification, which can solve problems such as inappropriate statistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

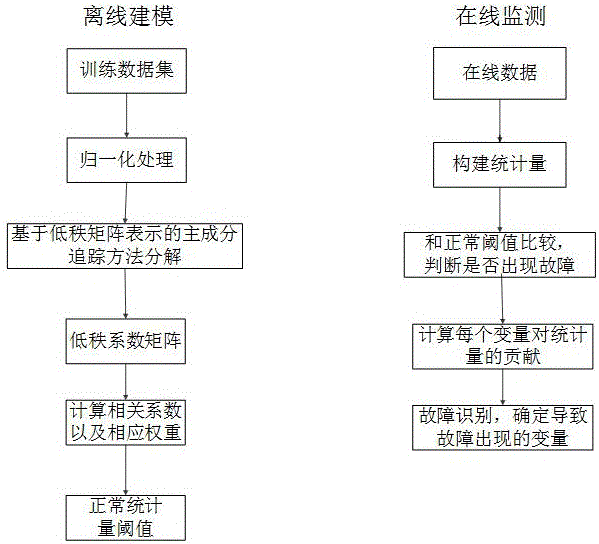

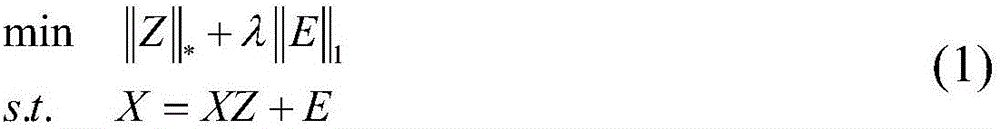

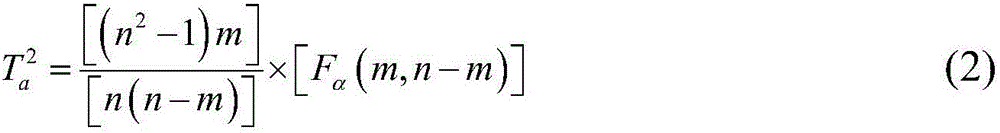

Method used

Image

Examples

Embodiment

[0076] Blast furnace ironmaking is an important link in steel production and an important indicator to measure a country's economic level and comprehensive national strength. It is very necessary to ensure the safe and stable operation of large-scale blast furnace system in terms of economy and safety, so it is of great significance to study the abnormal working condition diagnosis and safe operation methods of large-scale blast furnace.

[0077] During blast furnace production, iron ore, coke, and flux (limestone) for slagging are loaded from the top of the furnace, and preheated air is blown in from the tuyeres located at the lower part of the furnace along the periphery of the furnace. At high temperature, the carbon in coke (some blast furnaces also inject auxiliary fuels such as pulverized coal, heavy oil, and natural gas) burns with the oxygen blown into the air to generate carbon monoxide, and removes the oxygen in the iron ore during the process of rising in the furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com