Device and method for producing special-shaped superconducting cable for magnet

A technology of superconducting cables and superconducting cables, applied in conductor/cable supply devices, cable/conductor manufacturing, circuits, etc., can solve problems such as uneven surface of cables, damage to superconducting strands, uneven void ratio, etc. Achieve uniform pay-off tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

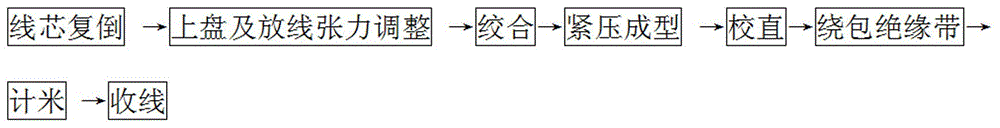

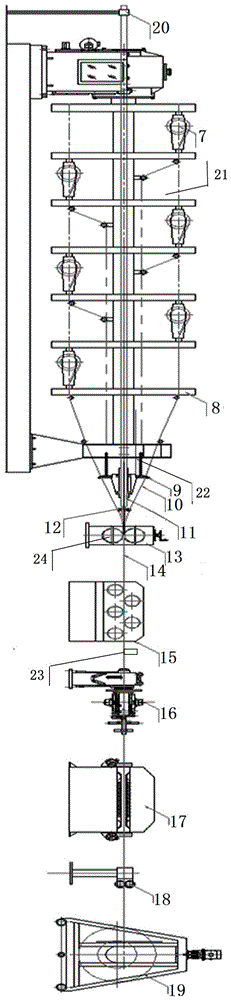

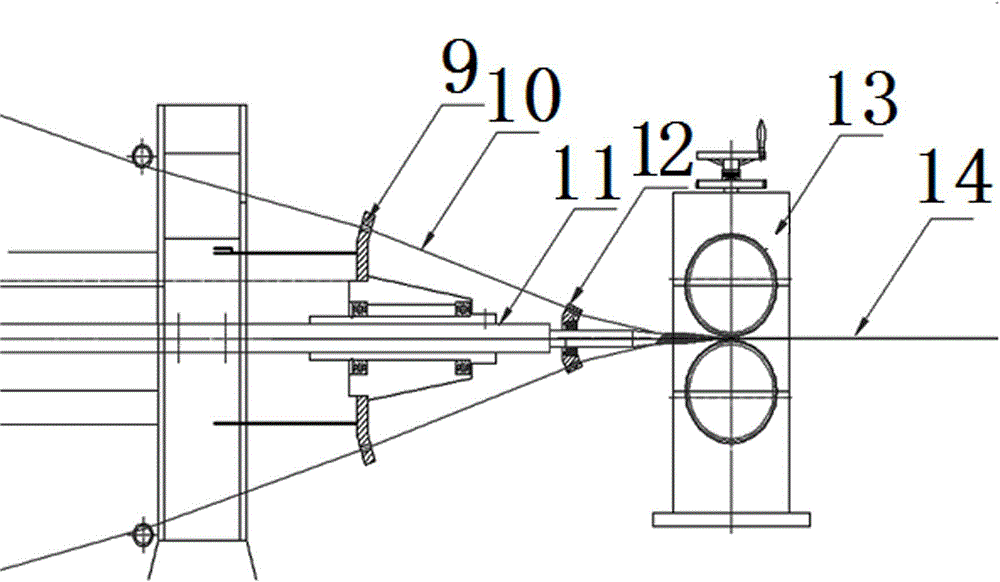

[0030] A device for producing special-shaped superconducting cables for magnets, comprising an inner support core fixing frame 20 arranged in sequence, a twisted cage 7, a compression die 13 composed of upper and lower compression wheels, a cable straightening machine 15, and an insulating tape Material winding machine 16, crawler tractor 17, take-up and discharge control machine 18, take-up reel 19; winch cage includes winch cage main shaft 22, winch cage pay-off frame 8 is installed on the winch cage main shaft 22, winch cage pay-off stand 8 A twisted cage pay-off reel 24 matched with the twisted cage main shaft 22 is installed on the top, an inner support core 11 is provided in the twisted cage main shaft 22, and the rear end of the inner support core 11 is connected with the inner support core fixing frame 20, and the inner support core 11 From back to front in the front end area, there are fixed area 1, small branch ring installation area 2 for adjusting the front and rear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com