Power grading ring

A voltage equalizing ring and electric power technology, which is applied in the direction of circuits, electrical components, insulators, etc., can solve the problems of inconvenient installation and maintenance, easy discharge of the open ring body, and increased cost, so as to achieve a more stable mechanical structure and good voltage regulation Conduction effect, rapid pressure equalization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

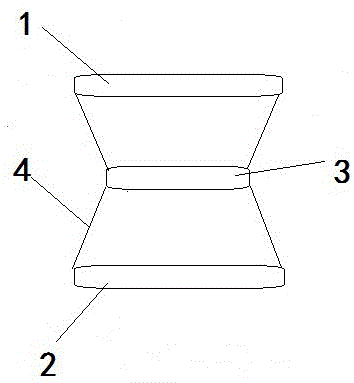

[0022] A voltage equalizing ring for electric power, comprising a titanium alloy upper ring body and a titanium alloy lower ring body with equal diameters, a nickel alloy intermediate ring body is arranged between the upper ring body and the lower ring body, the upper ring body, the lower ring body and the middle ring body The middle of the rings is parallel and coaxially arranged, and the adjacent rings are connected by connecting pieces arranged on the circumference of the rings. The diameter of the upper ring and the lower ring is larger than that of the middle ring.

[0023] The mass percentage composition of chemical elements in the middle ring of nickel alloy is: Co 6%, Mn 3%, W 1%, Al 0.7%, Mg 0.4%, Bi0.3%, Sr0.08%, Ba 0.07%, Cr0.04 ﹪, Zr0.03﹪, Ta 0.02﹪, B0.01﹪, the balance is Ni, the nickel alloy required for the nickel alloy intermediate ring is prepared, and the nickel alloy billet is heated to 1110-1120℃ in a 600-ton forging press Lower forging; then the temperature...

Embodiment 2

[0027] A voltage equalizing ring for electric power, comprising a titanium alloy upper ring body and a titanium alloy lower ring body with equal diameters, a nickel alloy intermediate ring body is arranged between the upper ring body and the lower ring body, the upper ring body, the lower ring body and the middle ring body The middle of the rings is parallel and coaxially arranged, and the adjacent rings are connected by connecting pieces arranged on the circumference of the rings. The diameter of the upper ring and the lower ring is larger than that of the middle ring.

[0028] The mass percentage composition of chemical elements in the middle ring of nickel alloy is: Co 7%, Mn 4%, W 2%, Al 0.8%, Mg 0.5%, Bi0.4%, Sr0.09%, Ba 0.08%, Cr0.05 ﹪, Zr0.04﹪, Ta 0.03﹪, B0.02﹪, the balance is Ni, the nickel alloy required for the nickel alloy intermediate ring is prepared, and the nickel alloy billet is heated to 1110-1120℃ in a 600-ton forging press Lower forging; then the temperature...

Embodiment 3

[0032] A voltage equalizing ring for electric power, comprising a titanium alloy upper ring body and a titanium alloy lower ring body with equal diameters, a nickel alloy intermediate ring body is arranged between the upper ring body and the lower ring body, the upper ring body, the lower ring body and the middle ring body The middle of the rings is parallel and coaxially arranged, and the adjacent rings are connected by connecting pieces arranged on the circumference of the rings. The diameter of the upper ring and the lower ring is larger than that of the middle ring.

[0033] The mass percentage composition of chemical elements in the middle ring of nickel alloy is: Co 6.5%, Mn 3.5%, W 1.5%, Al0.75%, Mg 0.45%, Bi0.35%, Sr0.085%, Ba 0.075%, Cr0. 045﹪, Zr0.035﹪, Ta0.025﹪, B0.015﹪, the balance is Ni, the nickel alloy required for the nickel alloy intermediate ring is prepared, and the nickel alloy billet is heated to 1110-1120 °C in 600 tons Forging under the forging press; af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com