Wafer hot-pressing ultrasonic ball planting device and process

A hot-pressed ultrasonic and wafer technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of long heating time, increased equipment identification time, chip burns on the wafer, etc., and achieves the goal of heating The effect of shortening the time, shortening the recognition time, and preventing chip burn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

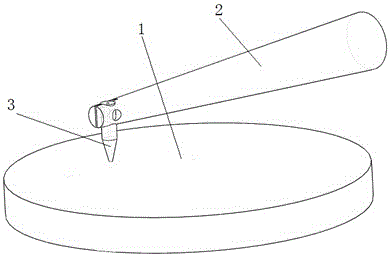

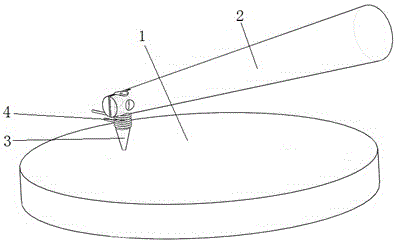

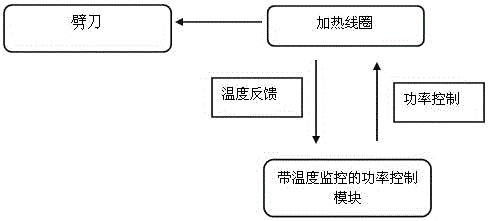

[0018] see figure 2 , it can be seen from the figure that the wafer hot-pressing ultrasonic ball planting device of the present invention includes a heating table 1, an ultrasonic rod 2 and a rivet 3, and the rivet 3 is installed at the front end of the ultrasonic rod 2. Based on the original equipment structure, the present invention cancels the heating function of the heating table so that it is only used for placing wafers. A heating coil 4 is added at the position of the riving knife 3, and the heating coil 4 is used to directly heat the riving knife 3 to the required process temperature. Through heat conduction, the temperature of the gold wire is raised, and then through the same ultrasonic structure as the original, the energy is transferred to melt the gold wire and complete the ball planting process.

[0019] At the same time, use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com