A kind of rc-igbt device and preparation method thereof

A technology of device and collector area, which is applied in the field of power semiconductor devices, can solve problems affecting the reliability of RC-IGBT devices, current concentration and temperature unevenness, and increase the conduction voltage drop of diodes, so as to solve the problem of current and temperature uniformity The problem of good forward conduction voltage drop and short-circuit loss, the effect of low IGBT forward conduction voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and characteristics of the present invention will be further described below in conjunction with the accompanying drawings, and the examples given are only for explaining the present invention, and are not intended to limit the scope of the present invention.

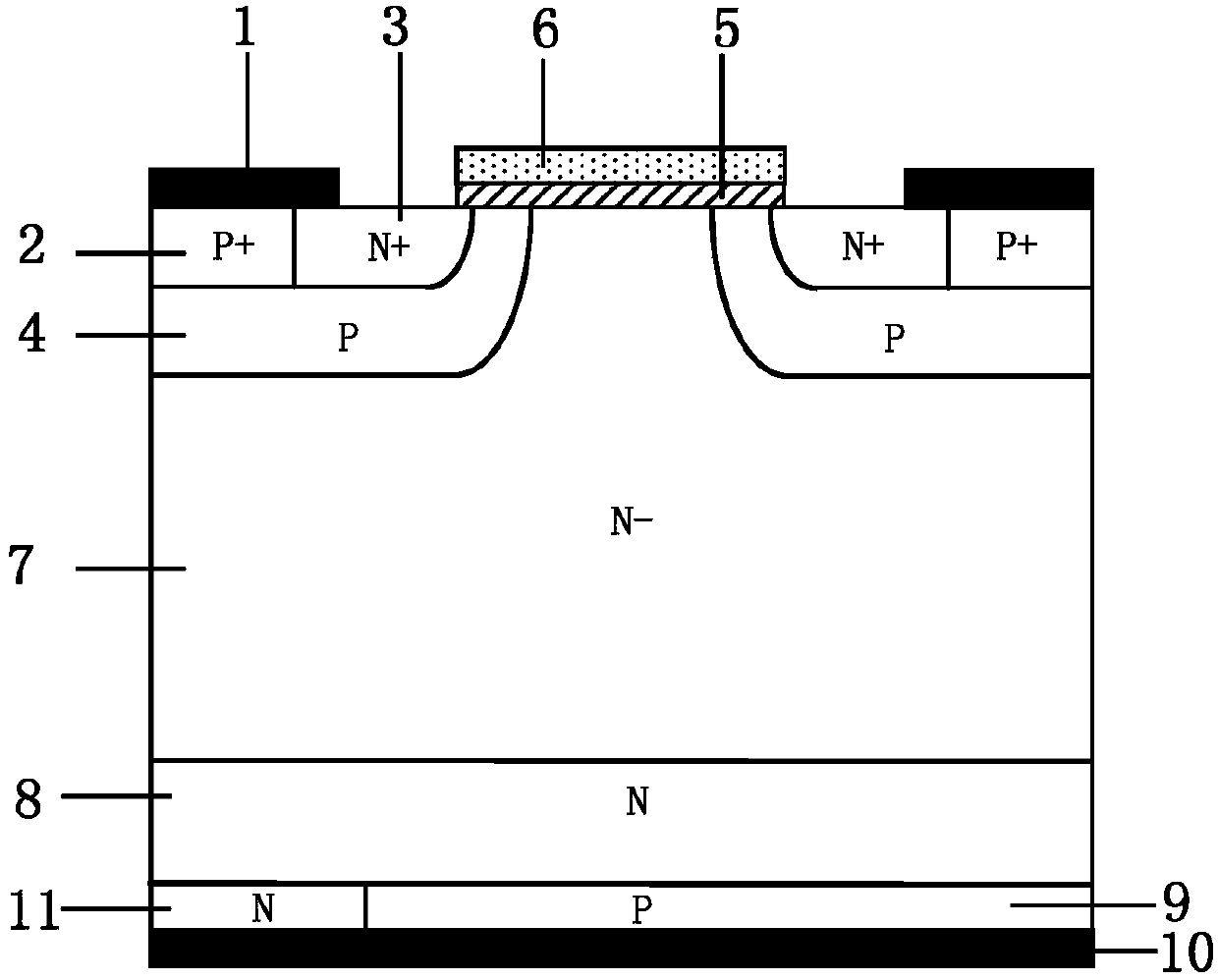

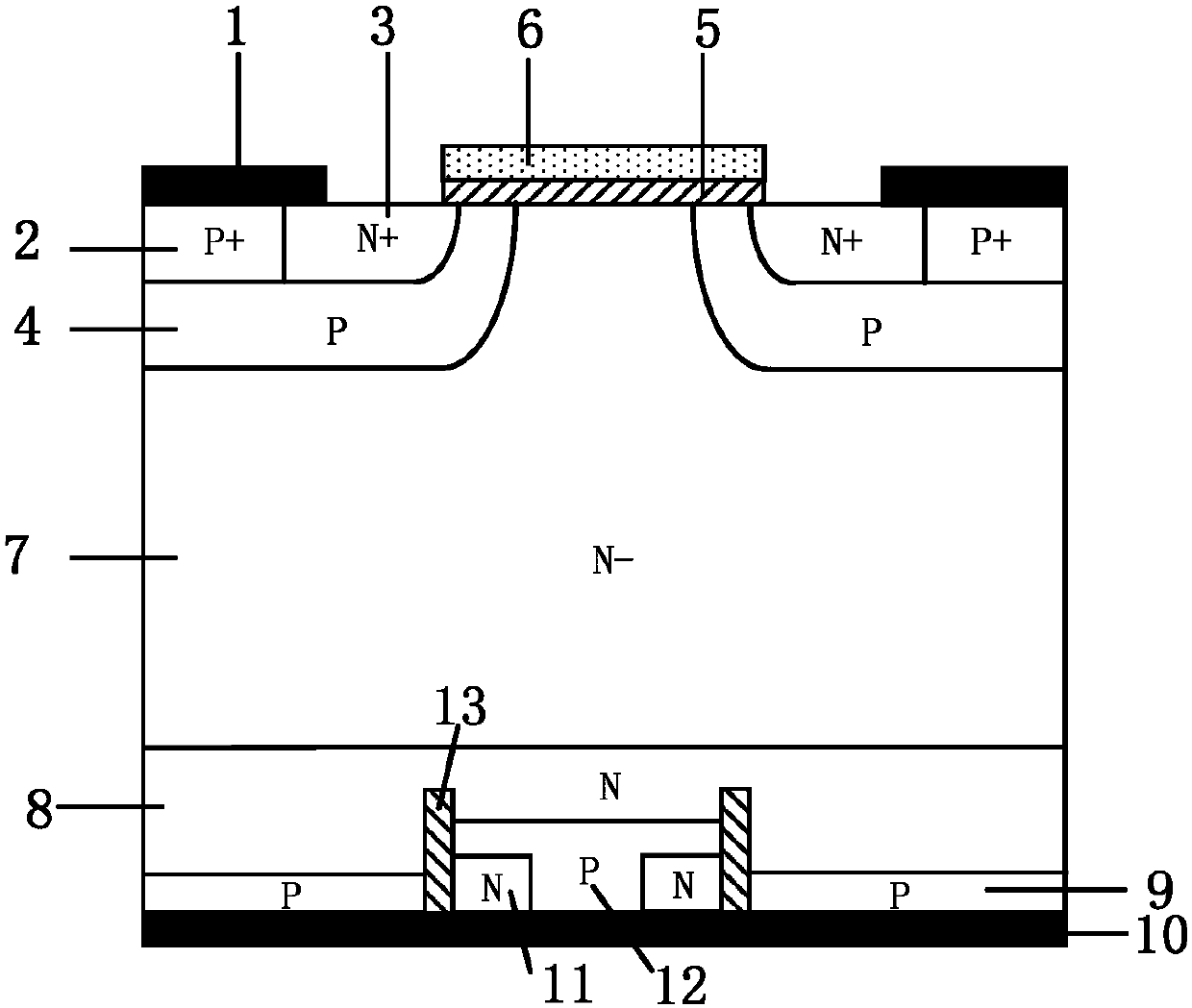

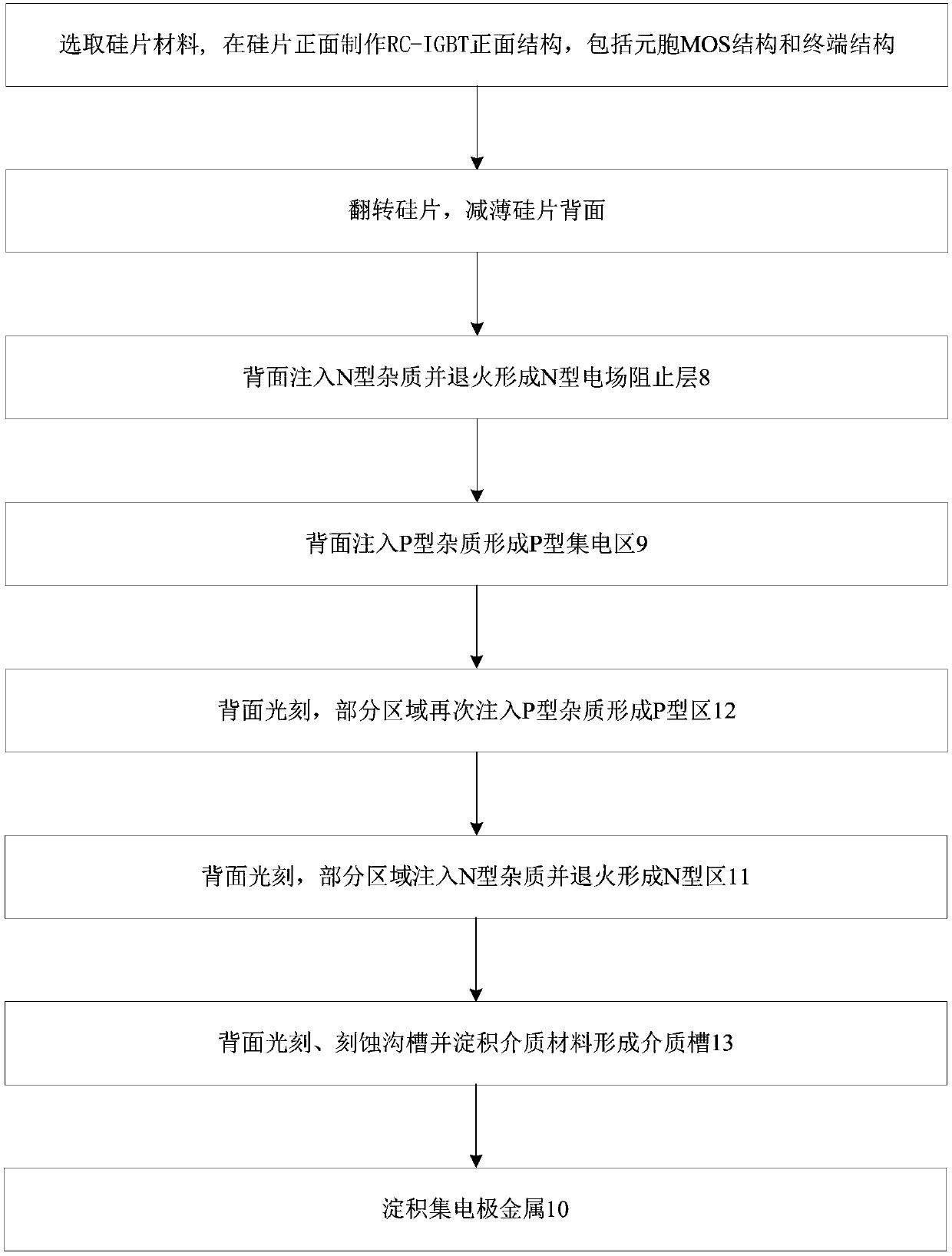

[0031] This embodiment provides an RC-IGBT device with a voltage level of 600V, and its cell structure is as follows figure 2 As shown, it includes emitter structure, gate structure, collector structure and drift region structure. The emitter structure includes metal emitter 1, P+ ohmic contact region 2, N+ emitter region 3 and P-type base region 4, where P+ The ohmic contact region 2 and the N+ emitter region 3 are independently arranged in the P-type base region 4, and the surfaces of the P+ ohmic contact region 2 and the N+ emitter region 3 are in contact with the metal emitter 1; the drift region structure includes N- The drift region 7 and the N-type electric field stop layer 8, the N-type el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com