Circulating type edge chipping driving system

A driving system, cyclic technology, applied in photovoltaic power generation, sustainable manufacturing/processing, electrical components, etc., can solve the problems of complex control system, high cost, many driving structures, etc., to ensure the edge trimming effect and low cost of use , to ensure the effect of cutting edge accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

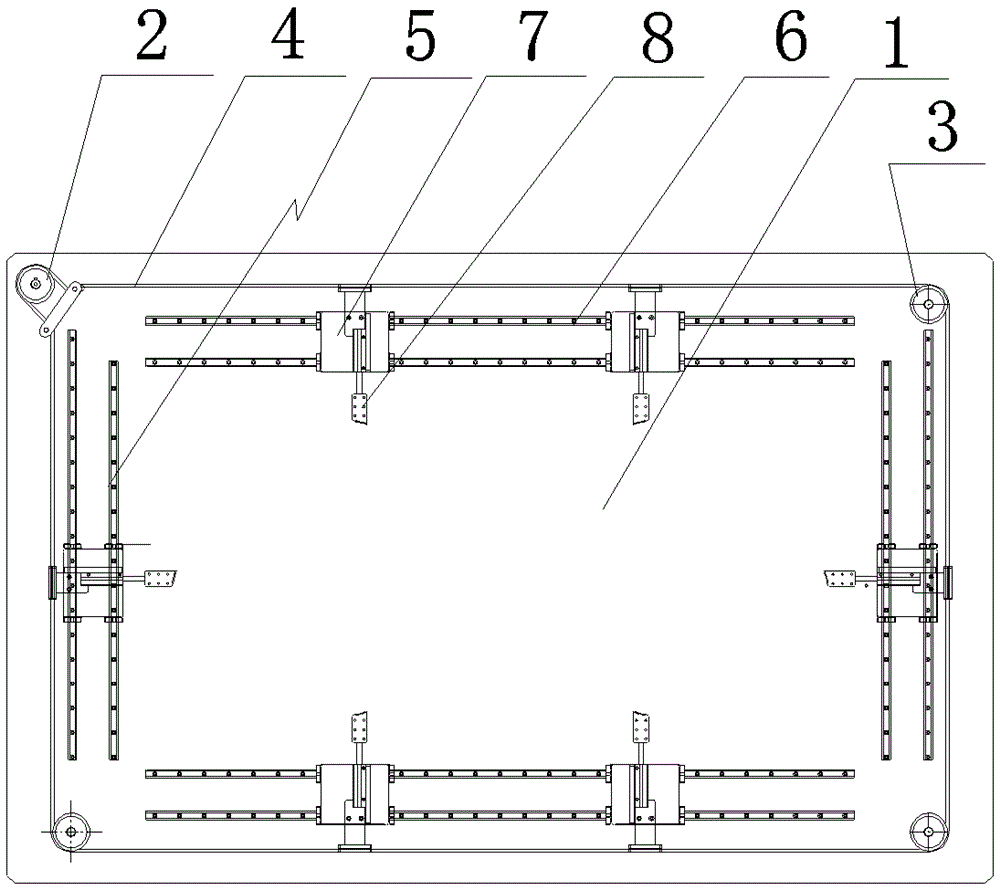

[0009] See figure 1 As shown, a circular chamfering drive system includes a mounting plate 1, a driving synchronous pulley 2 is installed on one corner of the mounting plate 1, a reversing synchronous pulley 3 is respectively installed on the other three corners, and a synchronous belt 4. After bypassing the driving synchronous pulley 2 and the reversing synchronous pulley 3 in sequence, it forms a rectangular shape. The inner side of the synchronous belt 4 is arranged on four guide rails 5, and each guide rail 5 is composed of two parallel linear guide rails 6 The four guide rails 5 form a rectangular shape corresponding to the synchronous belt 4, each guide rail 5 is equipped with a sliding seat 7, and each sliding seat 7 is fixedly connected to the synchronous belt 4, and the sliding seat 7 is equipped with a cutting Edge Knife8. Two sliding seats 7 are installed on the wire guide rail 5 corresponding to the long side of the rectangle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com