Laminated glazing comprising a profiled clipping bead

A technology of glass windows and glass sheets, applied in windshields, glass/slag layered products, windows, etc., can solve the problems of invisibility, reduce the field of view, etc., and achieve the effect of increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

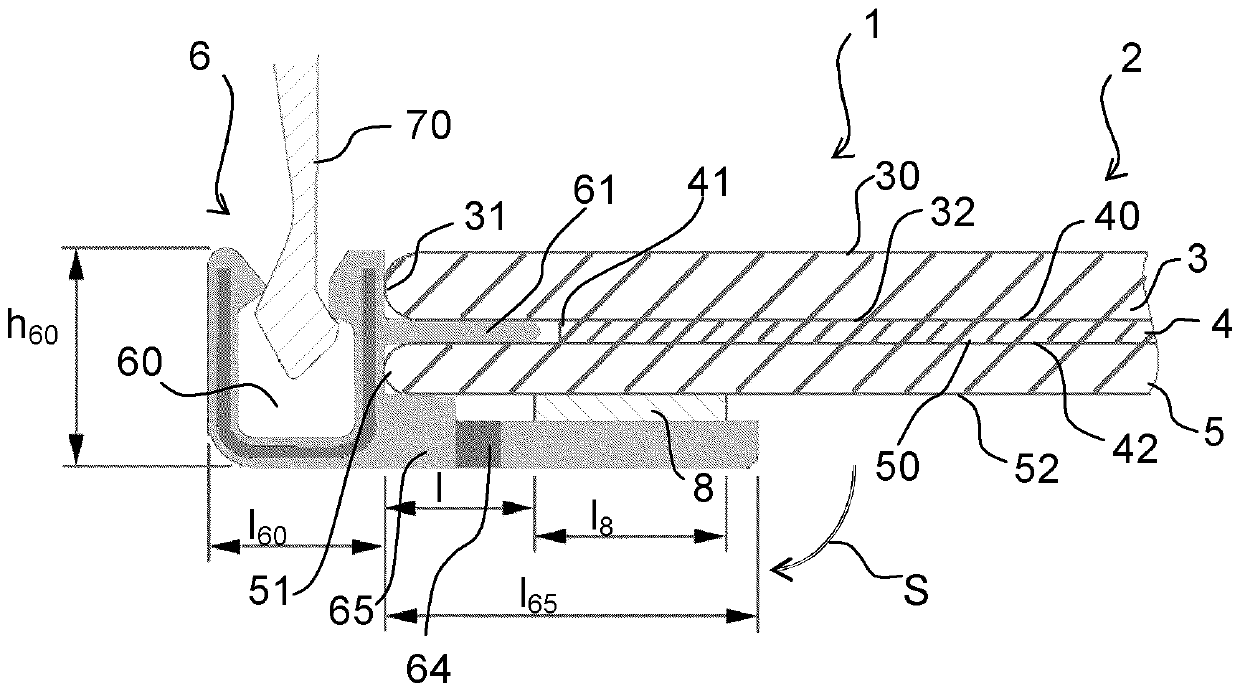

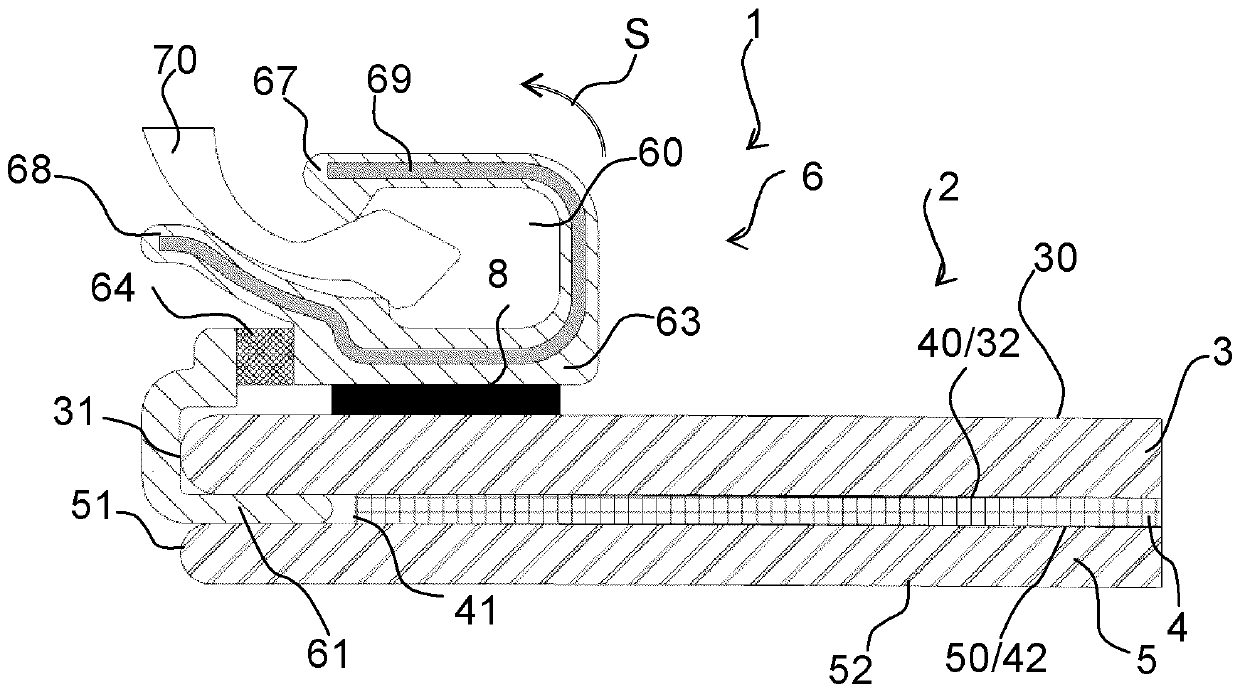

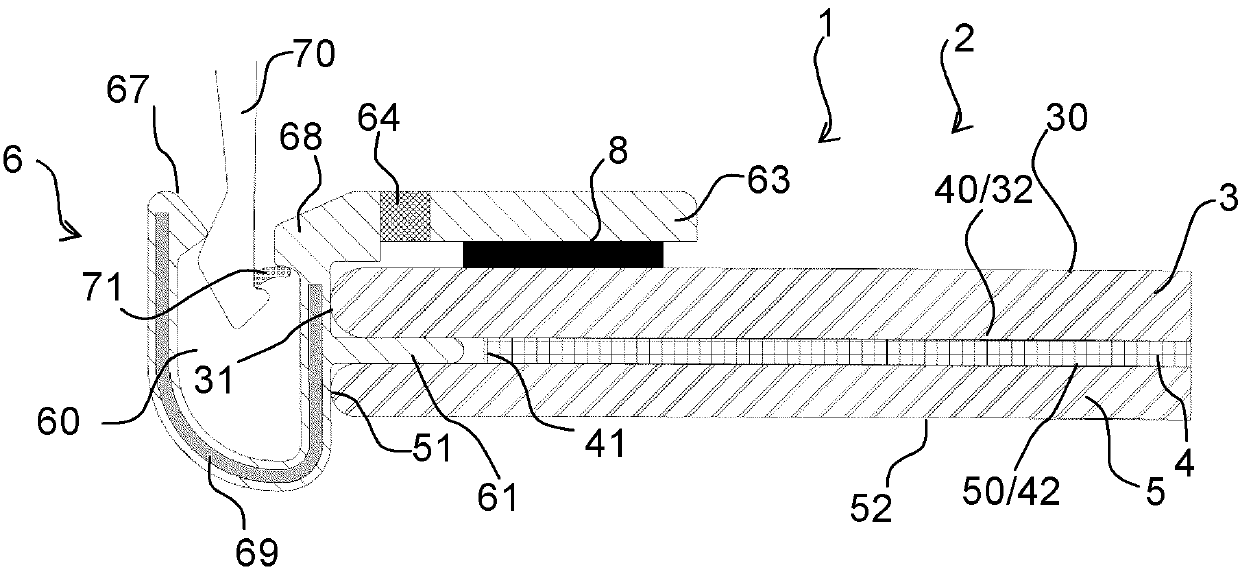

[0082] The present invention relates to such figure 1 A partially visible glazing 1 comprising a laminated glazing element 2 comprising an outer glass sheet 3, an inner glass sheet 5 and an interlayer plastic sheet between said two glass sheets 4.

[0083] The invention is described by way of example in the context of its application as a vehicle glazing, which enables a separation between an exterior space E outside the vehicle and an interior space I inside the vehicle. The ideas of "outside" and "inside" are therefore considered with respect to this outside space E and this inside space I accordingly.

[0084] In the figures, the glass sheets are each shown as having rounded edge faces; however, these edge faces may be straight, and the corners between the edge faces and faces are then right angles.

[0085] The invention is described in particular in the context of application to vehicle windshields, and more particularly, in the context of application to the left edge o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com