Waste water decontamination

A technology for wastewater and preparations, applied in the fields of water pollutants, water/sewage treatment, chemical instruments and methods, etc., which can solve the problems of specificity, limited general use, increased process complexity, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

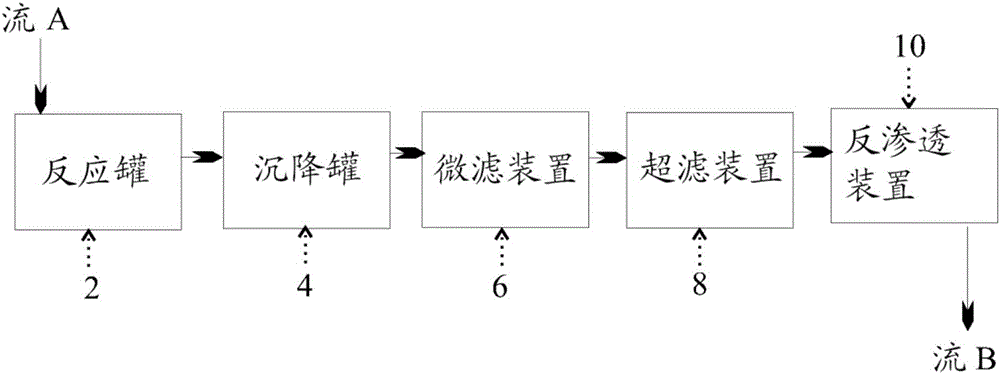

Method used

Image

Examples

Embodiment 1

[0073] Example 1: Preparation of Formulations of the Disclosure

[0074] First 0.1 g of sodium hydroxide was mixed in 0.9 g of deionized water to obtain a 10% sodium hydroxide solution. This 10% sodium hydroxide solution was further mixed with 40 g of cationic starch solution (ISC 2500N, pH 6.5) (obtained from Industrial Specialty Chemical (ISC) Inc., USA) to produce an alkalized cationic starch solution with a pH of 12.5. This alkalized cationic starch solution was then blended with 2 kg of liquid sodium aluminate (Nalco 2, pH 12.5) obtained from Nalco at 150 rpm at 25°C to obtain 2.041 kg of the formulation of the present disclosure.

Embodiment 2

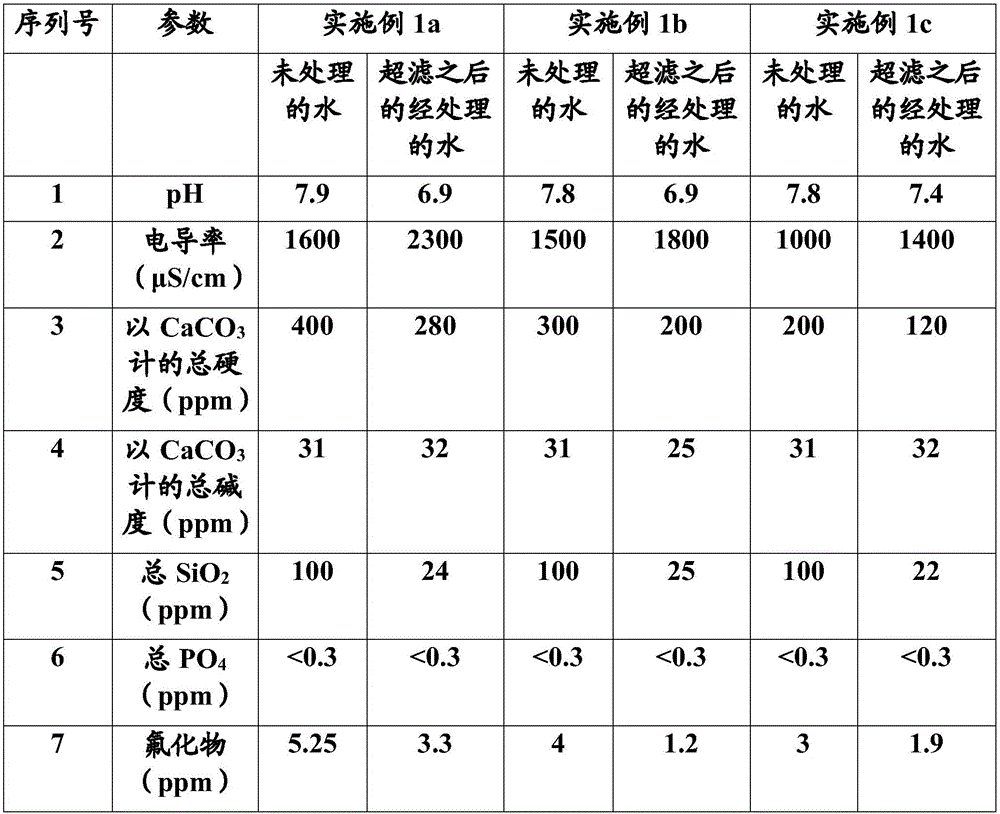

[0075] Example 2: Method for Removing Inorganic Contaminants

[0076]Tests were carried out in a laboratory shock tester in which 400 ppm of the formulation prepared in Example 1 was dosed to waste water from the steel industry (cooling tower discharge) and mixed for a time interval of 3 minutes to 5 minutes. 1 ppm of anionic flocculant (a powdered copolymer of acrylic acid and acrylamide in a molar ratio of 3:7) was then added to each resulting mixture and allowed to settle for 30 minutes. In each case, the supernatant layer was filtered in a glass filter flask loaded with 20 micron filter paper, then the pH was adjusted to 6.5 to 7.0, and the supernatant layer was loaded with 1,00,000 Daltons of polyvinylidene fluoride (PVDF). Dead-end ultrafiltration is performed in the dead-end filter chamber of the ultrafiltration membrane. The purified water obtained after each test was analyzed; the results of some tests are presented below:

[0077] Table 1: Degree of pollutant reduc...

Embodiment 3

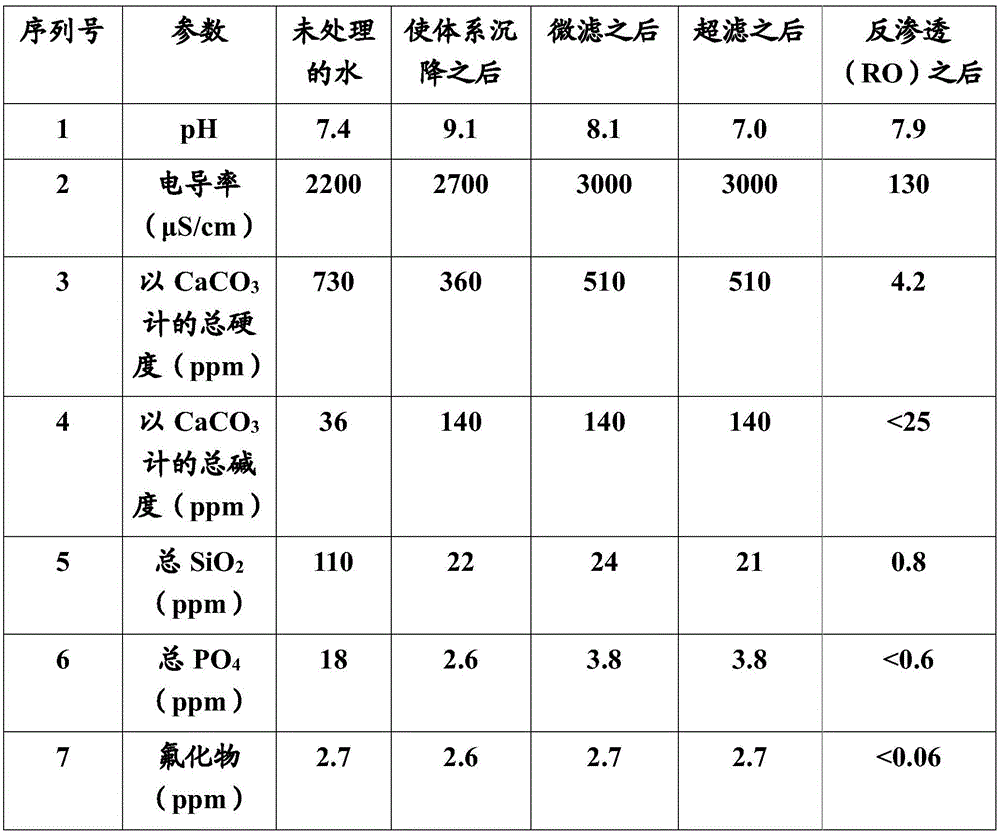

[0080] Example 3: Method for Removing Inorganic Contaminants

[0081] Experiments were carried out in a laboratory shock tester in which different levels of formulations according to the invention and soda ash were dosed and mixed for a time interval of 3 minutes to 5 minutes into wastewater from the steel industry (cooling tower discharge). In each case, a powdered copolymer of acrylic acid and acrylamide in a molar ratio of 3:7 was added to the resulting mixture as an anionic flocculant and allowed to settle for 30 minutes. The supernatant layer was filtered in a glass filter flask loaded with 20-micron filter paper, then adjusted to pH 6.5 to 7.0, and filtered on a death cell packed with a 1,00,000 Dalton polyvinylidene fluoride (PVDF) ultrafiltration membrane. Dead-end ultrafiltration is performed in an end-filter chamber. The ultrafiltered water obtained in each case was subjected to reverse osmosis in dead-end filter chambers equipped with Dow BW-30RO membranes. The pu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap