Humidity-resistant self-suspending proppants

A proppant, self-suspension technology, applied in the direction of production fluid, wellbore/well components, drilling composition, etc., can solve the problem of destroying free flow characteristics, and achieve the effect of reducing the humidity-caking problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Together with 13.5 g of commercially available anionic polyacrylamide inversion emulsion containing approximately equal amounts of high molecular weight hydrogel-forming anionic polyacrylamide copolymer, water and hydrocarbon carrier liquid, 500 g of 30 / 50 mesh sand is added to Hobart-type mixer. 1.5 g of glycerin was also added so that the weight ratio of the hydrogel-forming polymer to glycerin in the composition was about 3:1. The mixture was then stirred at the slowest speed of the mixer for 7 minutes and separated into multiple 100 g samples.

[0101] Separately, a 50% by weight solution of pMDI (polymerized methylene diphenyl diisocyanate) covalent crosslinker in toluene was prepared. 0.4 g of this pMDI / toluene mixture (representing a pMDI / polymer weight ratio of 0.22:1 and a pMDI / glycerol ratio of about 0.66:1) was added to one of the 100 g samples, stirring was continued using Speedmixer, and then dried. A second 100 g sample used as a control was prepared in exa...

Embodiment 2

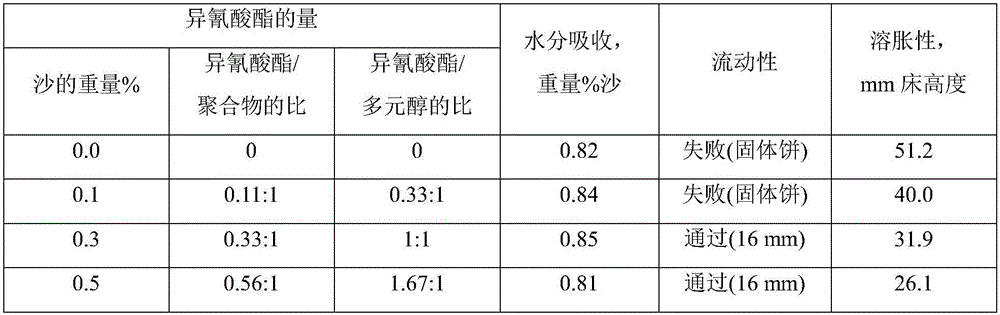

[0105] Three samples each containing 100g 30 / 50 sand were added to three separate FlackTek cups. Separately, a commercially available anionic polyacrylamide inverted emulsion containing 10% by weight of glycerin and 90% by weight of an anionic polyacrylamide copolymer containing approximately the same amount of high molecular weight hydrogel-forming hydrogel, water and a hydrocarbon carrier liquid was prepared. The coating composition. The weight ratio of the hydrogel-forming polymer to glycerin in the coating composition is about 3:1.

[0106] Then 3 g of the coating composition was added to the top of each FlackTek cup, and then the containers were covered, and their contents were mixed at 800 rpm for 30 seconds.

[0107] A commercially available liquid pMDI (polymerized methylene diphenyl diisocyanate) containing an average of about 4-5 methylphenyl isocyanate groups per molecule was added to each container in different amounts. . Cover the container again and mix for 30 seco...

Embodiment 3

[0118] Another characteristic of our self-suspending proppants described in our previous application is that their hydrogel coatings disintegrate rapidly when these proppants reach their final use position downhole. This property is desirable because it releases the proppant particle substrate used to prepare these proppants so that they can form proppant packs like conventional proppants and additionally support opening up cracks and fissures in their geological formations . As described further in our previous application, by including suitable hydraulic coagulation in the hydrogel-forming polymer coating of these proppants or in the aqueous fracturing fluid in which these proppants are used, or both Glue breakers can increase the disintegration.

[0119] In order to determine whether the technology of the present invention would adversely affect our self-suspending proppant's ability to disrupt separation, the following experiments were performed.

[0120] In the same manner a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com