Plate powder spraying non-contact isolating and color mixing pollution preventing device

A non-contact, injection device technology, applied in the direction of the injection device, can solve the problems of powder flying, isolation effect is not obvious, etc., to achieve the effect of ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

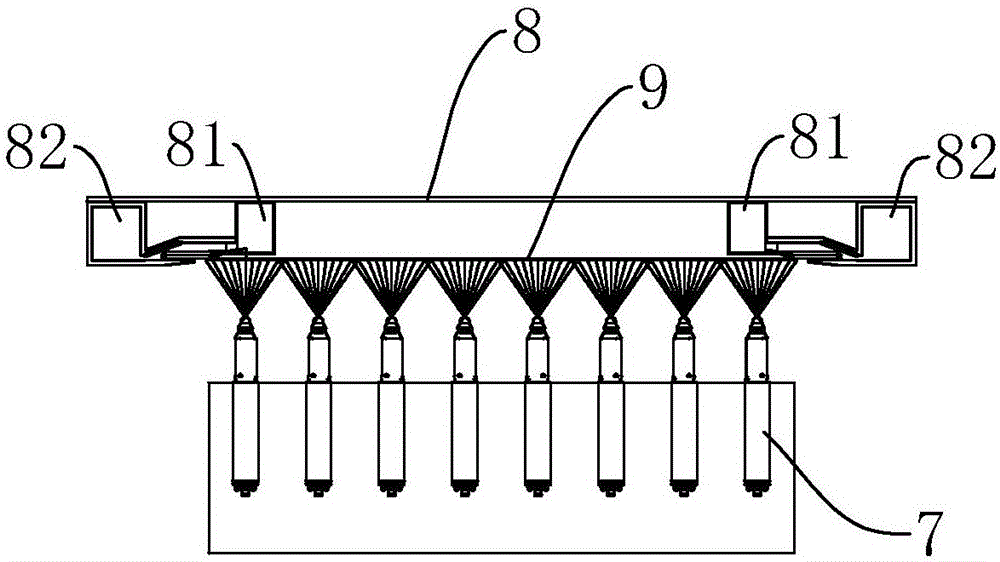

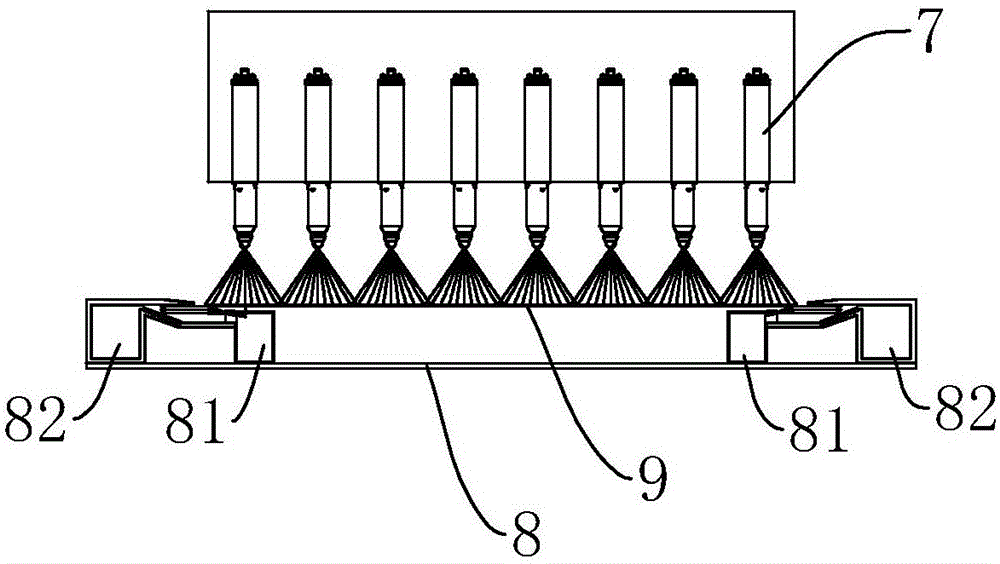

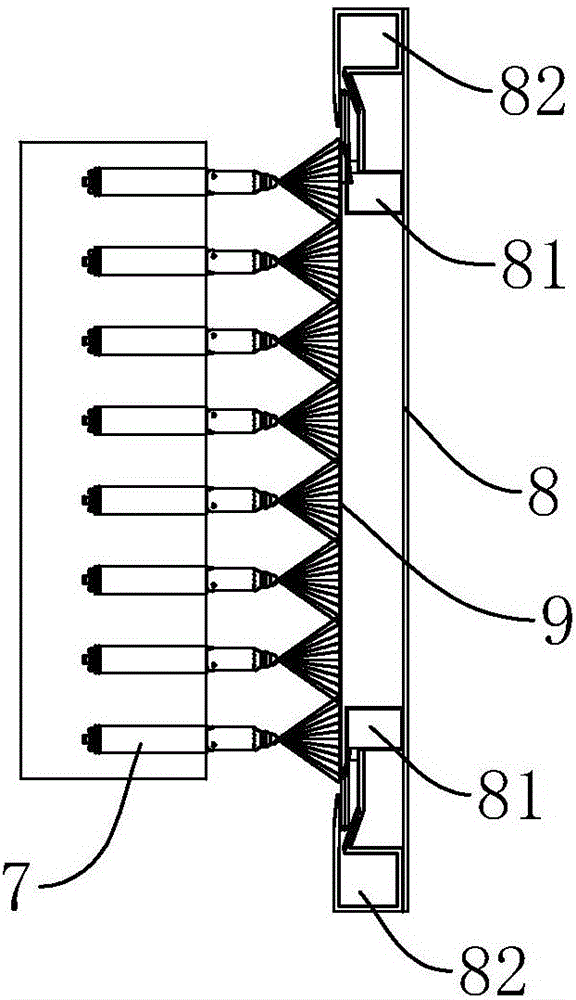

[0022] refer to figure 1 , Figure 5 , figure 1 , Figure 5 It is a structural schematic diagram of the first specific embodiment of the present invention. As shown in the figure, a non-contact isolation anti-mixing color pollution device for plate powder coating includes an isolated air-flow layer injection device and a negative pressure adsorption device. The isolated air-flow layer injection The device is installed on the side position of the non-spraying surface of the plate, and the negative pressure adsorption device is arranged in the advancing direction of the isolation air flow injection of the isolation air flow layer injection device or near the edge of the plate, so that the isolation air flow layer injection device and the negative pressure adsorption device An isolated airflow layer is formed between them. When the overspray powder floats and moves to the side of the non-sprayed board surface, it will be isolated by the isolated airflow layer, lifted and spraye...

Embodiment 2

[0033] In the specific implementation process of the present invention, it is also possible to select the scheme of using a negative pressure adsorption device alone to form an isolated airflow layer, such as Figure 6 as shown, Figure 6 It is a schematic structural diagram of the second specific embodiment of the present invention. In this embodiment, a separate negative pressure adsorption device is used to form an isolated airflow layer, which can also achieve the effect of powder isolation and anti-pollution and color mixing. work efficiency.

[0034] The negative pressure adsorption device can be composed of one or more negative pressure adsorption ports 6, and the angle b between the direction of the adsorption airflow of the negative pressure adsorption ports 6 and the end surface of the plate can be 0° to 270°, all of which can form a negative pressure on the plate. The isolation airflow layer isolated from the non-sprayed surface can all achieve the isolation effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com