Polishing and screening device for rolling bodies for bearings

A screening device and rolling body technology, applied in the cleaning method using gas flow, machine tools suitable for grinding the edge of workpieces, filter screens, etc., can solve the problem of increasing labor procedures, powder chips cannot be discharged in time, and the grinding area is small. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

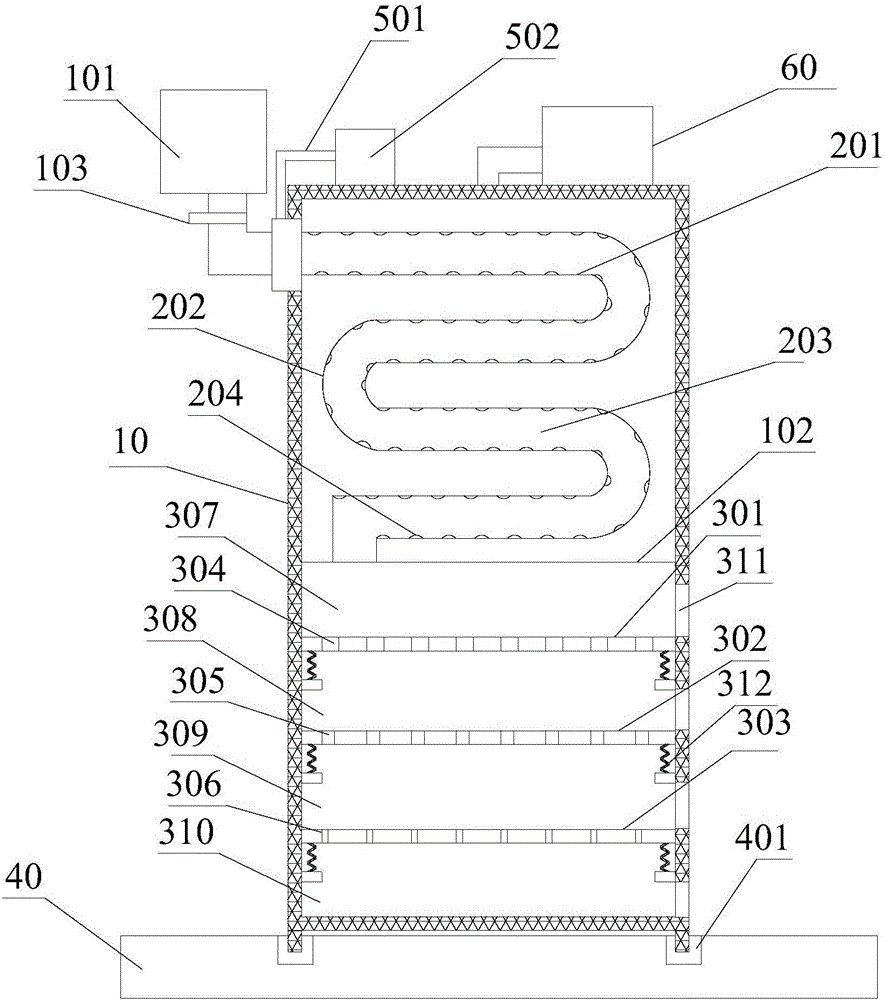

[0015] refer to figure 1 , the present invention proposes a grinding and screening device for bearing rolling bodies, including a base 40, a box body 10, and a grinding device, wherein:

[0016] The base 40 is provided with an annular chute 401 , the bottom of the box body 10 is clamped in the annular chute 401 , the end of the box body 10 away from the base 40 is connected to the driving mechanism 60 , and the driving mechanism 60 drives the box body 10 to rotate. The upper end of one side of the box body 10 is provided with a quantitative feeding funnel 101, the quantitative feeding funnel 101 is provided with a quantitative feeding valve 103, and the box body 10 is provided with a partition 102, which separates the inside of the box body 10 from top to bottom. into a grinding area and a receiving area.

[0017] The grinding device is arranged in the grinding area. The grinding device includes several U-shaped tubes 201 arranged at equal intervals. Any adjacent two U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com