Micro-fluidic chip liquid feeding fixture and liquid feeding method

A microfluidic chip, liquid feeding technology, applied in the directions of clamping, manufacturing tools, supports, etc., can solve the problems of difficult chip removal, large time difference, low alignment accuracy, etc., to achieve a wide range of temperature and pressure tolerance, Low cost and strong chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below through specific embodiments and accompanying drawings.

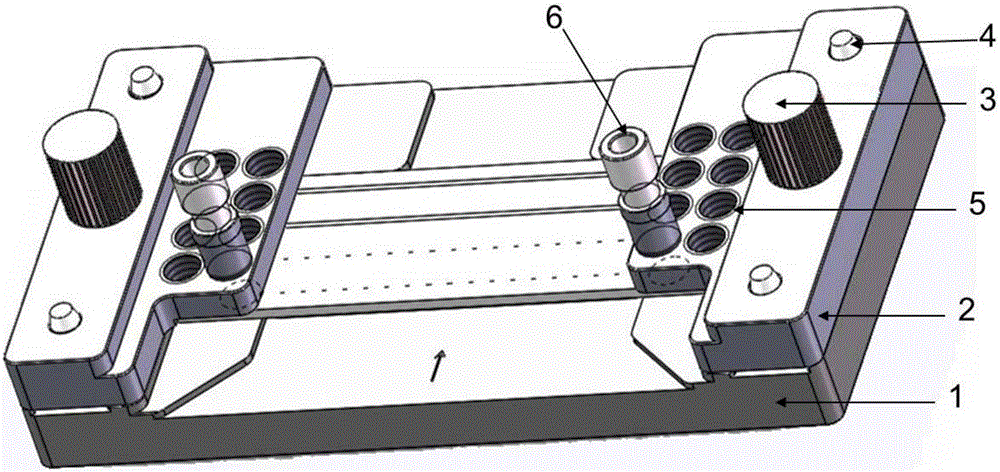

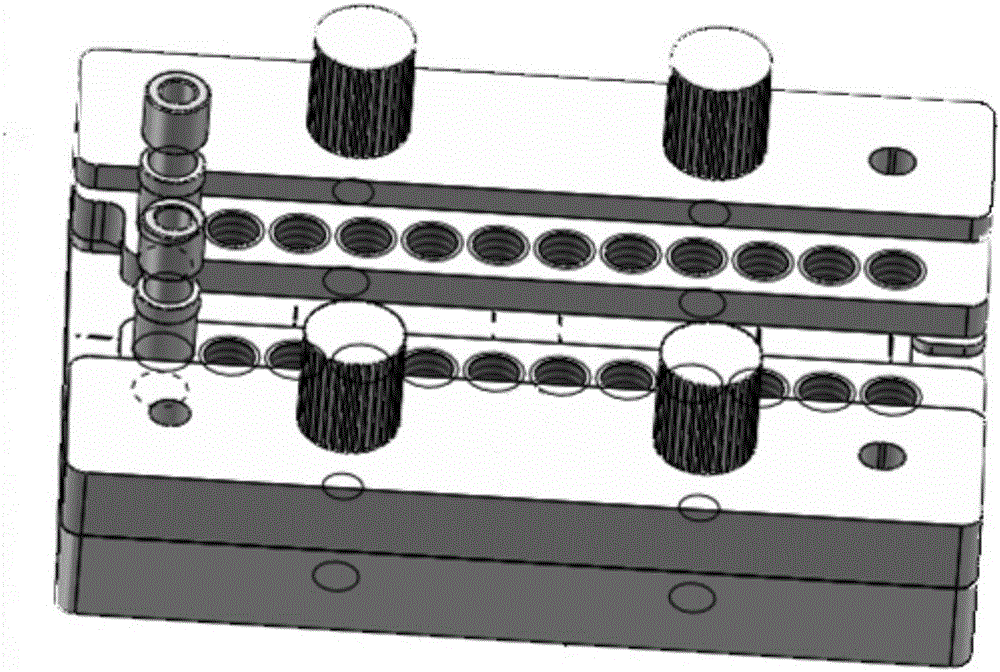

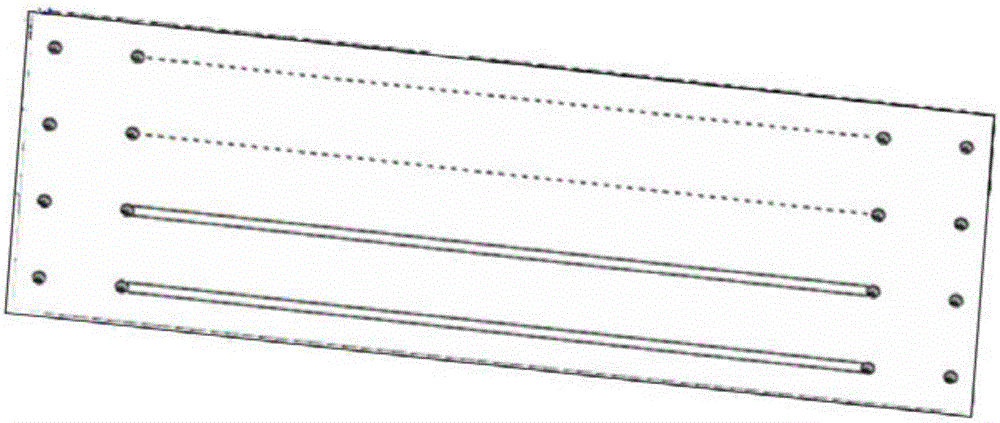

[0036] figure 1 It is a structural schematic diagram of the microfluidic chip fixture of this embodiment. The fixture includes a base 1 , a pressing block 2 , a locking screw 3 and a positioning pin 4 . Locating pin 4 is arranged on the base 1, and briquetting block 2 is provided with the locating hole that cooperates with locating pin 4, and locating pin 4 passes the locating hole on the briquetting block 2 during use, realizes the location to briquetting block 2; A cylindrical compression spring (not shown in the figure) can be arranged on 4, which is located between the pressing block 2 and the base 4, so that there is a certain distance between the pressing block 2 and the base 4, which is convenient for fixing the microfluidic chip. The locking screw 3 is used to lock and fix the pressing block 2 . The pressing block 2 is provided with a number of thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com