A transient control method for dynamic surface of manipulator servo system based on dead zone and friction compensation

A servo system and control method technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as dead zone and friction, explosive complexity of inversion methods, and uncertainty of model parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

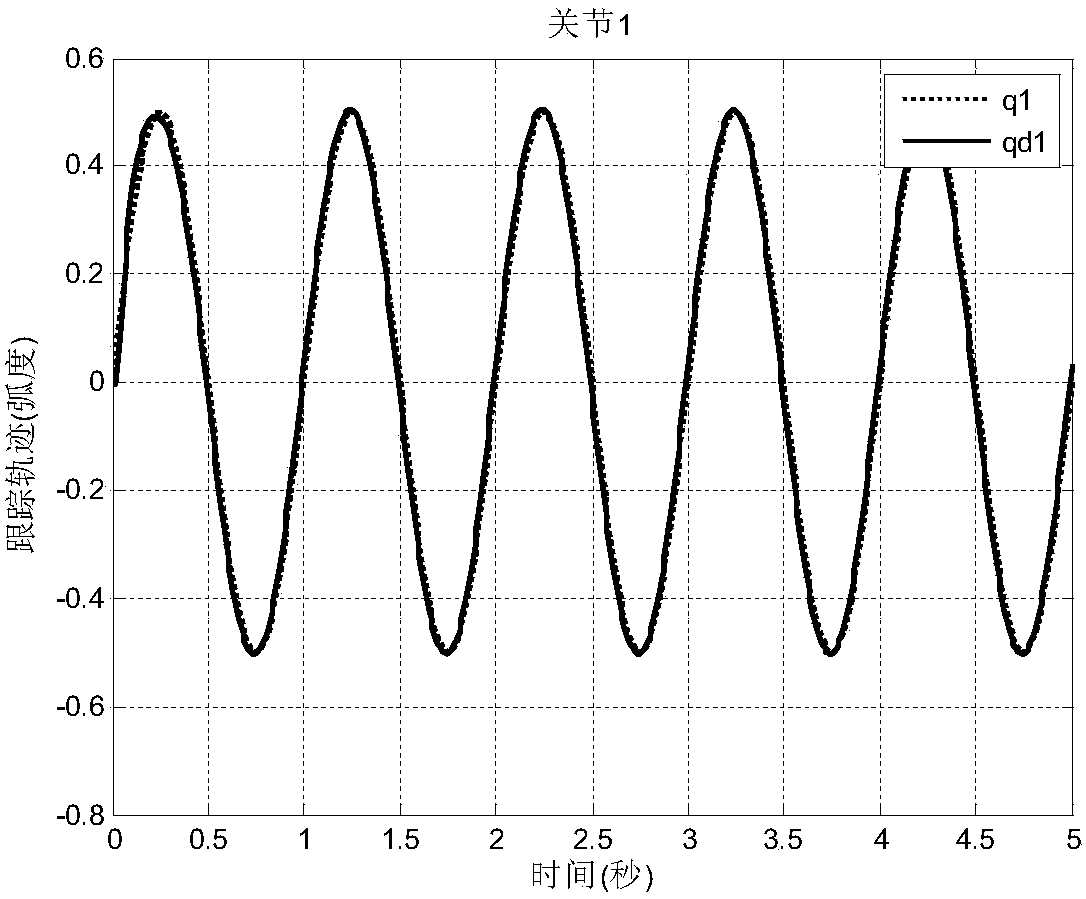

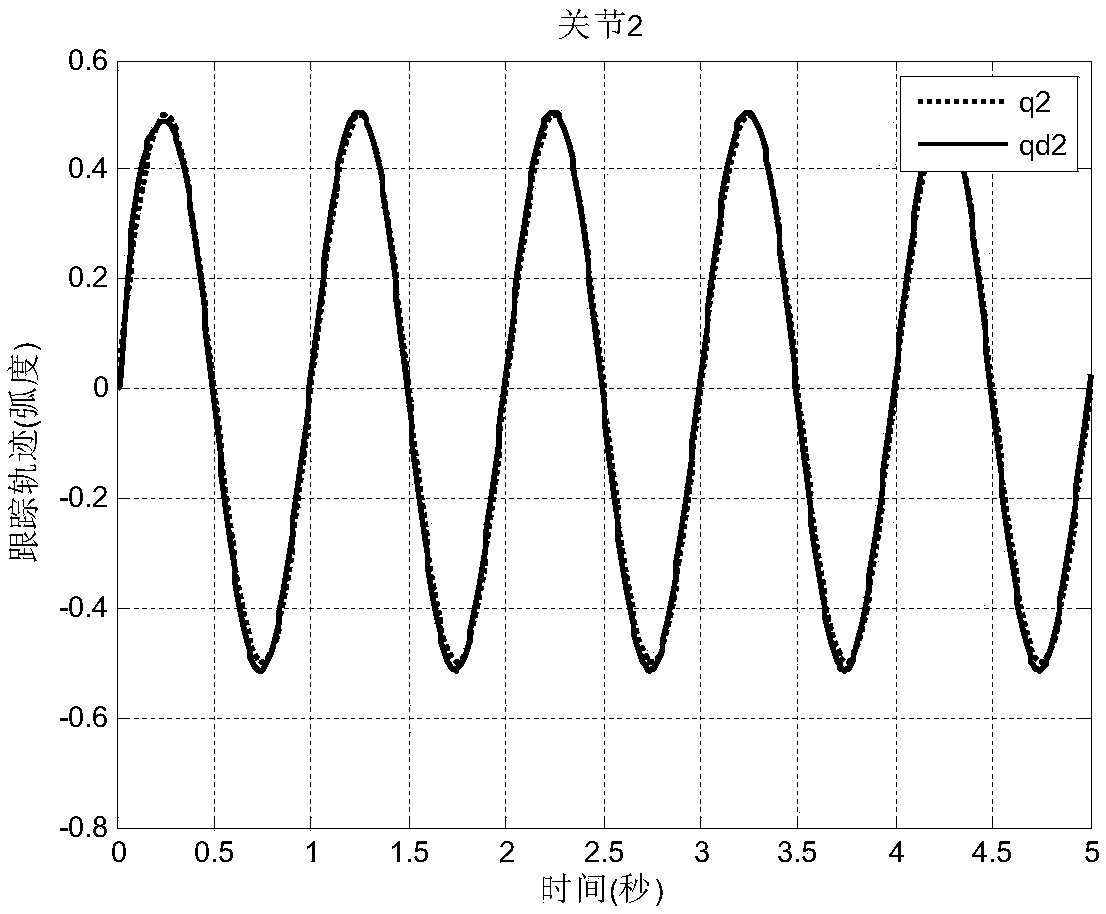

[0100] The present invention will be further described below in conjunction with the accompanying drawings.

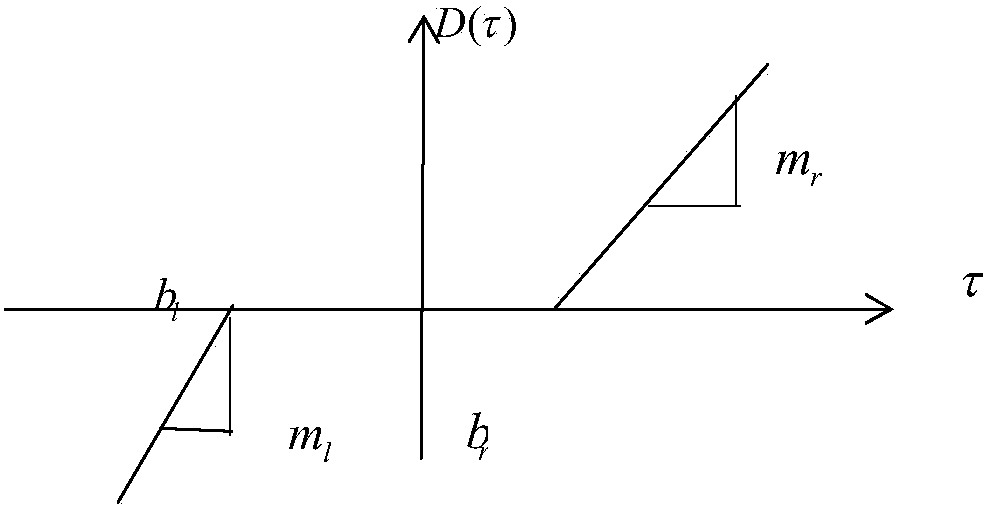

[0101] refer to Figure 1-Figure 5 , a dynamic surface transient control method of a manipulator servo system based on dead zone and friction compensation, comprising the following steps:

[0102] Step 1, establish the dynamic model of the servo system of the manipulator, initialize the system state, sampling time and control parameters, the process is as follows:

[0103] 1.1 The expression form of the dynamic model of the manipulator servo system is

[0104]

[0105] where, q, and are the positions, velocities and accelerations of the manipulator joints; M(q)∈R n×n is the symmetric positive definite inertia matrix of each joint; is the centrifugal Coriolis matrix for each joint; Diagonal positive definite matrix representing the damping friction coefficient; G(q)∈R n×1 stands for gravitational term; T L ∈ R n×1 is the interference term of the motor; τ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com