Continuous slicing machine for tubular propellant

A propellant and drug cutting machine technology, applied in metal processing and other directions, can solve the problems of large error and high degree of manual dependence, achieve good dimensional consistency, reduce labor intensity, and improve the effect of cutting drug yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

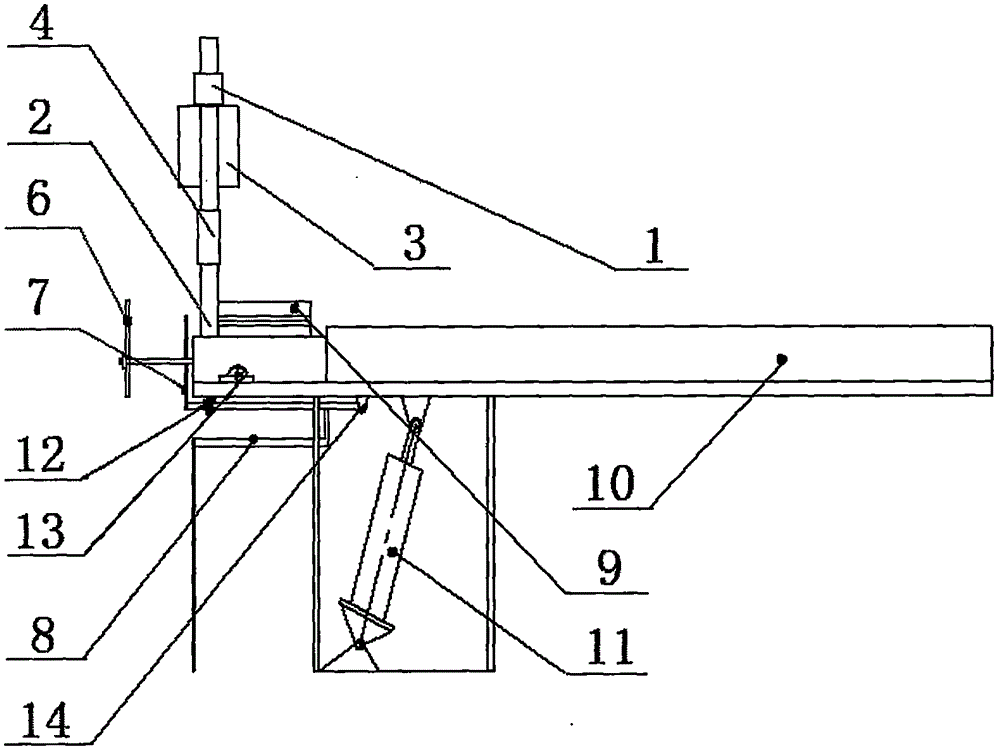

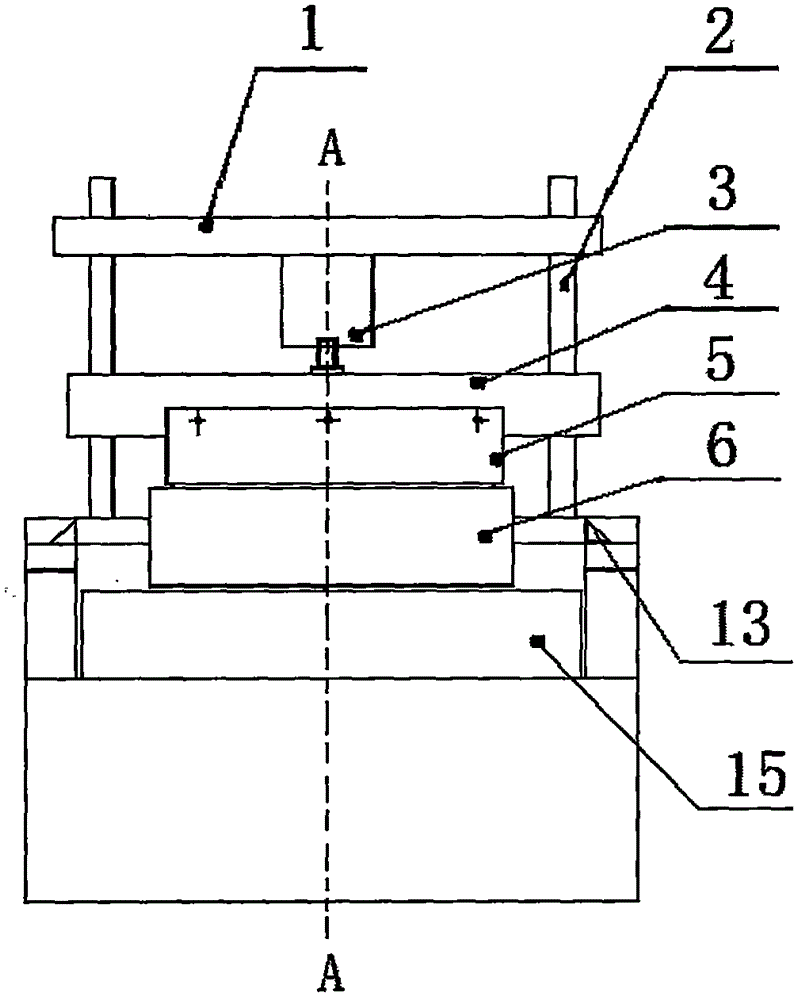

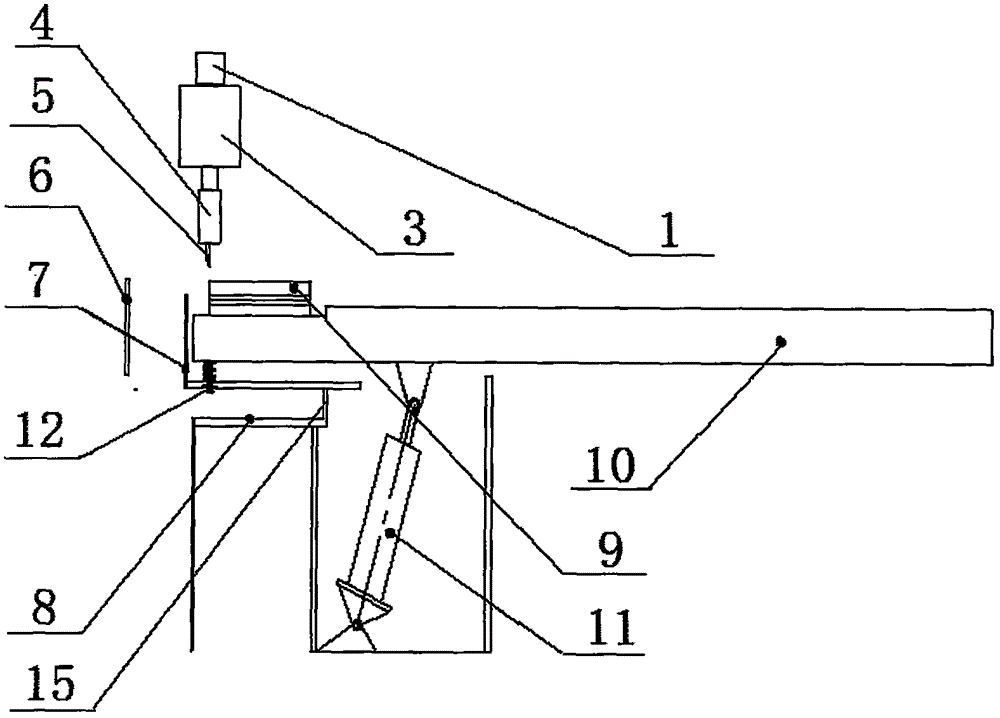

[0023] A kind of tubular propellant continuous cutting machine of the present invention, such as figure 1 As shown, it includes: upper beam 1, pillar 2, medicine cutting cylinder 3, lower beam 4, medicine cutting knife 5, positioning baffle 6, material cutting head baffle 7, machine base 8, medicine guide frame 9, workbench 10 , Workbench lifting cylinder 11, spring 12, workbench rotating shaft 13, baffle rotating shaft 14, vertical plate 15;

[0024] The upper end of the machine base 8 is two support plates extending horizontally and parallel to each other, and the lower end of the two support plates of the machine base 8 is fixed with a vertically extending vertical plate 15;

[0025] The workbench 10 is a flat plate whose rear end width is greater than the distance between the two support plates of the machine base 8 and whose front end width is smaller than the distance between the two support plates of the machine base 8;

[0026] The cutting head baffle 7 is fixed by tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com