Low noise diamond saw blade

A diamond saw blade and low-noise technology, which is applied to stone processing equipment, stone processing tools, manufacturing tools, etc., can solve the problems of physical and mental health injuries of construction workers, the effect of noise reduction is not obvious, and the strength of the saw blade matrix is reduced, so as to avoid Safety accidents, high bending strength, and the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

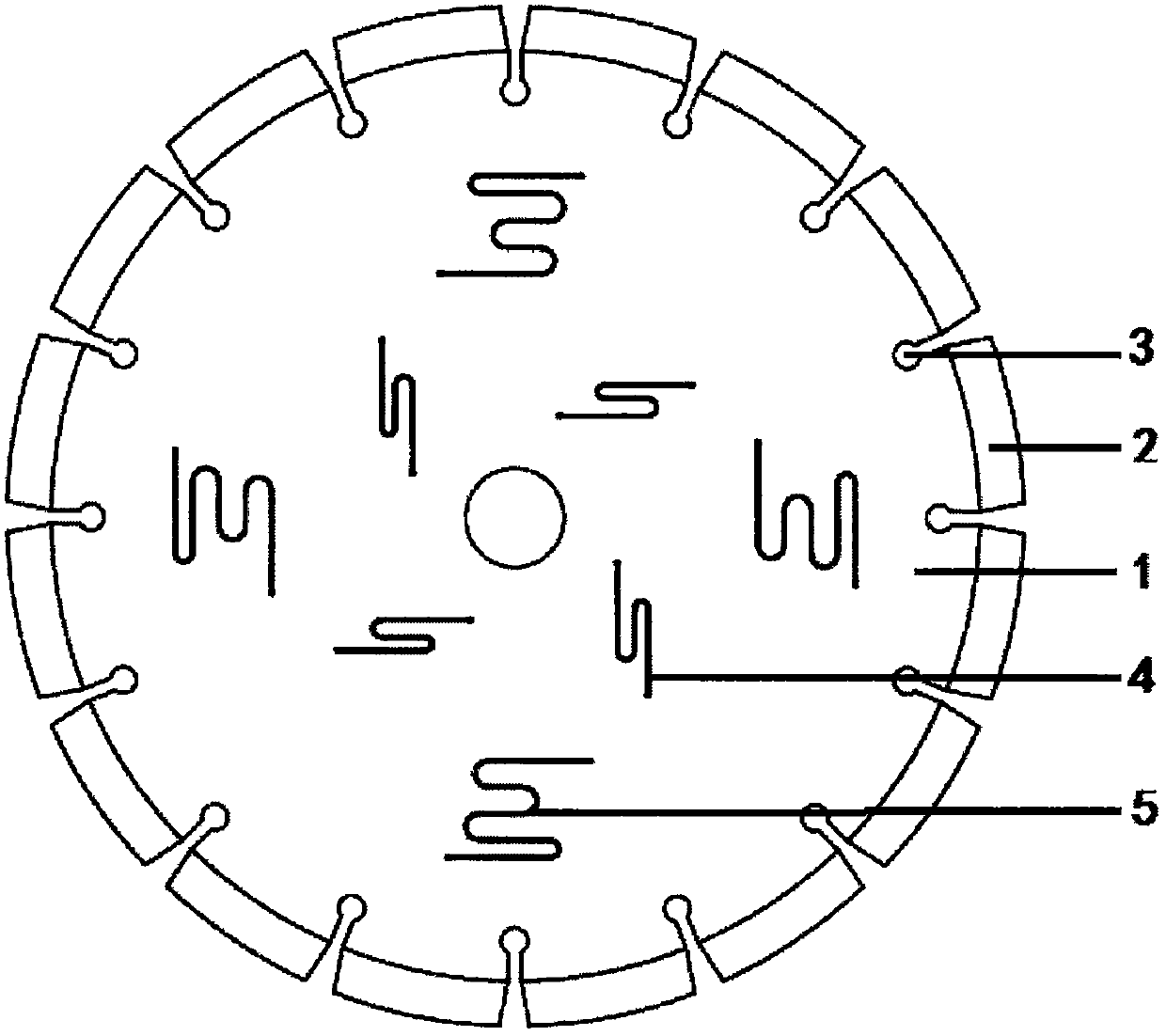

[0019] The low-noise diamond saw blade of the present embodiment comprises a circular steel substrate and 16 diamond cutter heads formed at the end of the circular steel substrate. Flutes. Four first sound-absorbing grooves are evenly distributed at a first distance from the center of the circular base body, and four second sound-absorbing grooves are evenly distributed at a second distance from the center of the circular base body; the second distance is twice the first distance, and the length of the second silencer is twice the length of the first silencer. The shapes of the first and second sound-absorbing grooves include straight lines parallel to each other and smooth curves between adjacent straight lines, and both ends of the first and second sound-absorbing grooves are provided with end blind holes. The cross-sections of the first and second sound-absorbing grooves are both semicircular, and the maximum width thereof is 0.5mm. The first and second sound-absorbing gro...

Embodiment 2

[0021] The low-noise diamond saw blade of the present embodiment comprises a circular steel substrate and 16 diamond cutter heads formed at the end of the circular steel substrate. Flutes. Four first sound-absorbing grooves are evenly distributed at a first distance from the center of the circular base body, and four second sound-absorbing grooves are evenly distributed at a second distance from the center of the circular base body; the second distance is twice the first distance, and the length of the second silencer is twice the length of the first silencer. The shapes of the first and second sound-absorbing grooves include straight lines parallel to each other and smooth curves between adjacent straight lines, and both ends of the first and second sound-absorbing grooves are provided with end blind holes. The cross-sections of the first sound-absorbing groove and the second sound-absorbing groove are semicircular, and its maximum width is 0.5 mm, and the first sound-absorb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com