Integrated die-cast alloy bicycle frame and die-casting method thereof

A frame and alloy technology, which is applied in the field of bicycle alloy die-casting frame and its die-casting, can solve the problems of open welding, material strength reduction, time-consuming processing and manufacturing, etc., and achieve the effect of simplifying the process and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: An alloy integral die-cast vehicle frame.

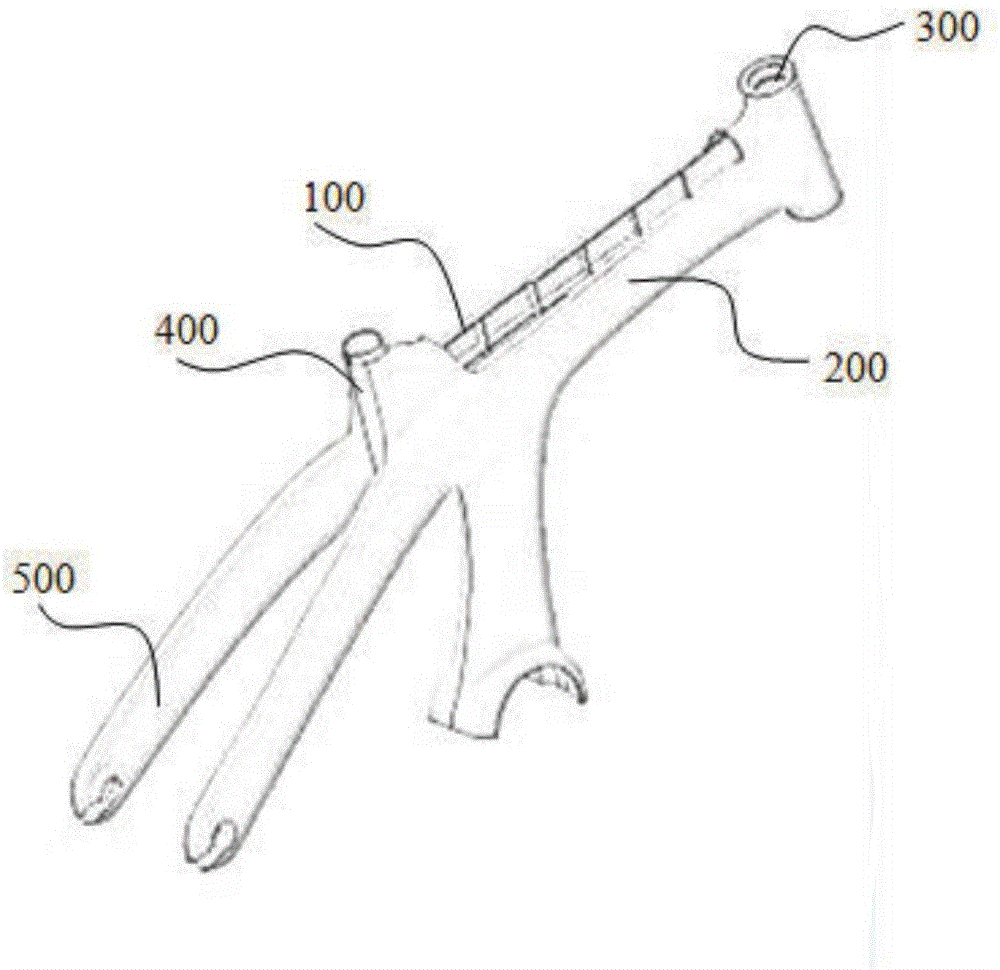

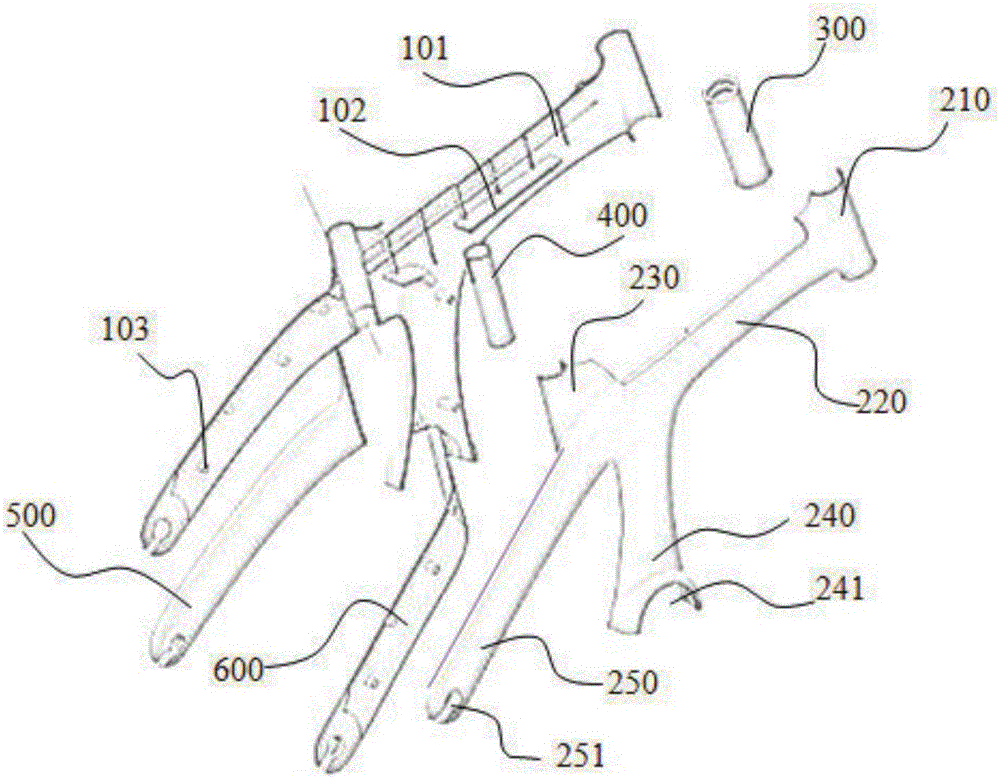

[0034] refer to Figure 1 to Figure 3 As shown, an alloy integral die-casting frame includes a first frame pressing part 100, a second frame pressing part 200, a first rear beam pressing part 500 and a second rear beam pressing part 600, the first The frame pressing part 100 and the second frame pressing part 200 are symmetrical structures, and the first frame pressing part 100 and the second frame pressing part 200 both include a front axle pressing part 210, a front beam pressing part joint part 220, seat press joint part 230, lower beam press joint part 240 and rear beam press joint part 250, the front axle press joint part 210, front beam press joint part 220, The seat pressing part 230 and the lower beam pressing part 240 are respectively connected with the front axle pressing part 210, the front beam pressing part 220, the vehicle seat pressing part 230 and the lower beam pressing part 200 in the second ve...

Embodiment 2

[0042] Embodiment 2: A pressing method of an alloy integral die-casting vehicle frame.

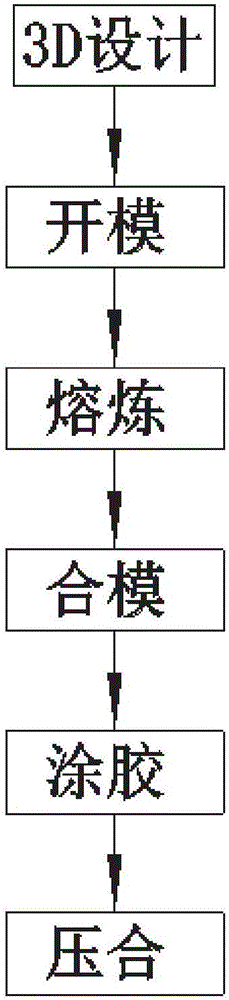

[0043] refer to Figure 1 to Figure 3 As shown, a press-fit method for an alloy integral die-casting vehicle frame specifically includes the following steps:

[0044] S1, 3D design: According to the requirements of the frame, the shapes of the first frame pressing part 100, the second frame pressing part 200, the first rear beam pressing part 500 and the second rear beam pressing part 600 are respectively adjusted. And the size is drawn, and the specific positions of the reinforcing rib 101, the reinforcing connecting plate 102 and the reinforcing connecting pipe 103 in each component are designed;

[0045] S2. Mold opening: according to the drawings drawn in step S1, separate independent molds are set up for the first frame press part 100, the second frame press part 200, the first back beam press part 500 and the second back beam press part 600. forming mold; simultaneously according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com