Efficient treatment process for slaughter wastewater

A technology for treating process and slaughter wastewater, which is applied in animal processing wastewater treatment, water/sewage treatment, flotation water/sewage treatment, etc. It can solve the problems that it is difficult to guarantee the effect of sewage treatment, and achieve the effect of improving the purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

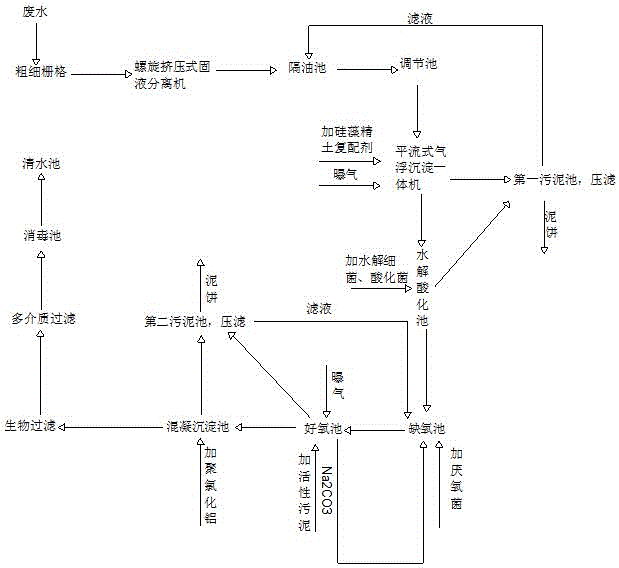

Image

Examples

Embodiment

[0049] A slaughterhouse produces 500m of waste water per day 3 , the designed sewage treatment station has a treatment capacity of 500m per day 3 , according to the law of sewage discharge, the system is designed to operate for 20 hours a day, and the sewage treatment capacity per hour is 25 m 3 , the water quality of the sewage is:

[0050] pH

Phosphate (P)

COD Cr

BOD 5

SS

NH 3 -N

Total coliform ≤

animal and vegetable oil

6-9

18-20mg / L

4000mg / L

2000mg / L

1500mg / L

60mg / L

36*10 12 pcs / 100mL

300mg / L

[0051] The treatment process is: the sewage is sequentially passed into

[0052] Coarse grid with a grid gap of 5 mm and a fine grid with a grid gap of 3 mm;

[0053] Screw extruding solid-liquid separator, extruding and filtering waste water;

[0054] The grease trap adopts brick-concrete structure with an effective volume of 50m 3 , to separate blood stains and grease;

[0055] Regulating pool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com