Preparation method of upconversion fluorescence nanometer material with nucleocapsid structure

A technology of fluorescent nanomaterials and core-shell structure, which is applied in the field of preparation of up-conversion fluorescent nanomaterials, can solve the problems of low product dispersibility and difficult removal of cycloethane, and achieve improved dispersibility, enhanced fluorescence, and simple preparation process easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

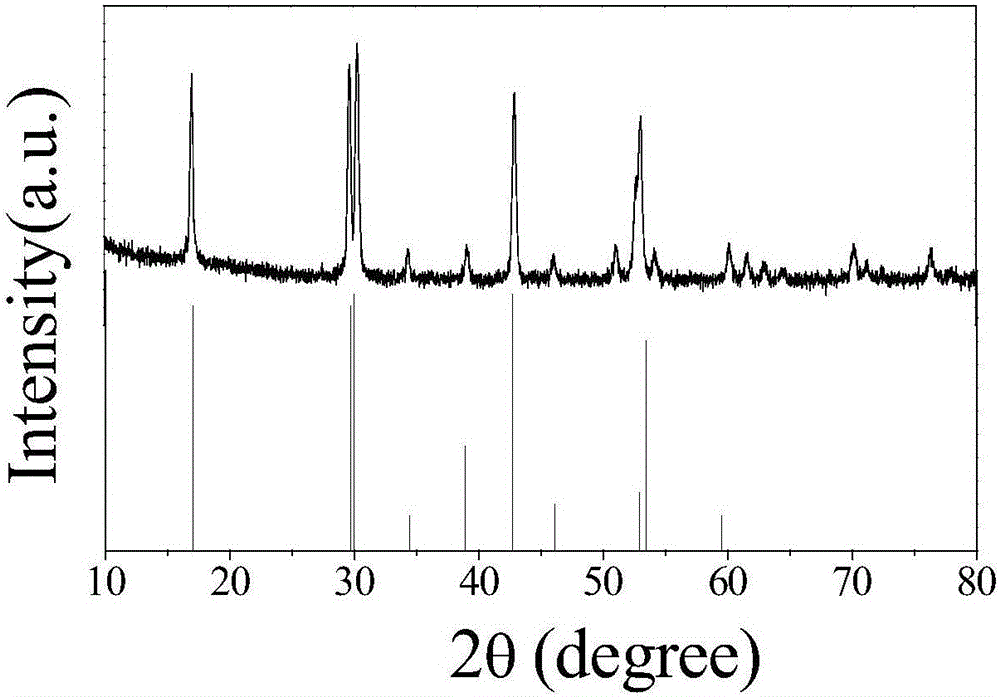

Embodiment 1

[0034] Upconversion fluorescent nanomaterial β-NaGdF 4 :20%Yb,2%Er@NaGdF 4 A method for preparing a core-shell structure, comprising the steps of:

[0035] (1) Prepare three kinds of solutions of 1, 2, and 3 respectively: weigh 0.4 mmol of rare earth oxide 1 (Ln 2 o 3 ), put the rare earth oxide 1 into a 50mL three-neck flask, add a small amount of deionized water (2-3mL) into it, heat up under magnetic stirring conditions, and set the temperature to 150°C. When the temperature rose to 80 °C, 1.5 mL of trifluoroacetic acid was added dropwise to the flask, and the solid was completely dissolved after a few minutes to obtain a transparent solution 1. Adopt the same method to weigh 0.6mmol rare earth oxide 2 (Gd 2 o 3 ) and 1.5mmol sodium hydroxide to prepare a transparent solution 2. Weigh 0.5mmol of sodium hydroxide solid into a 25mL three-necked flask, add a small amount of deionized water, and dropwise add 0.5mL of trifluoroacetic acid thereinto, until the solid is comp...

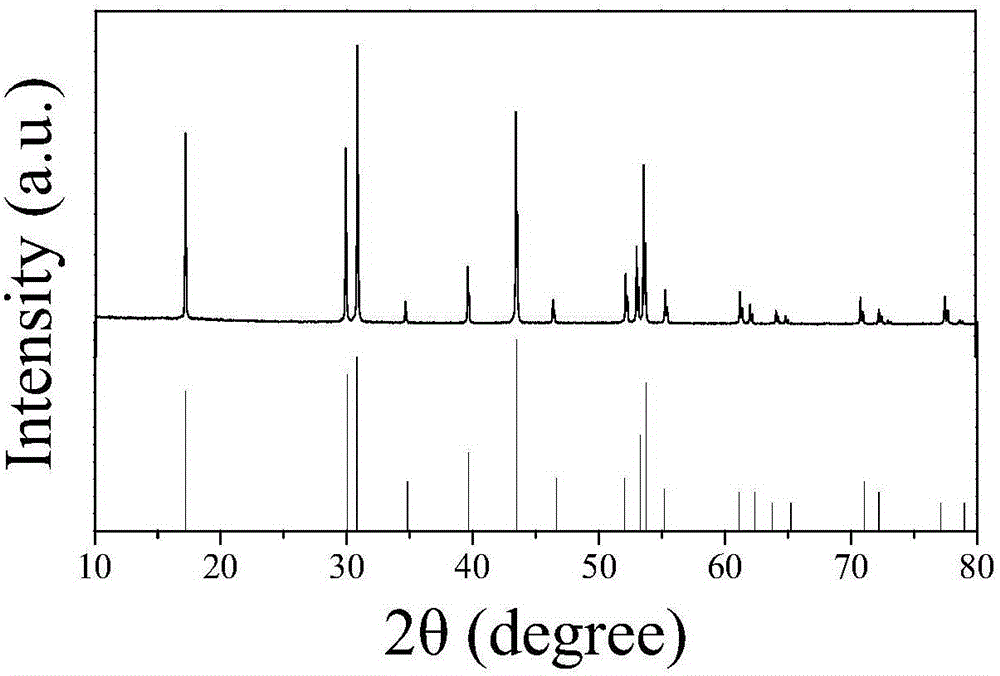

Embodiment 2

[0043] Upconversion fluorescent nanomaterial β-NaYbF 4 :2%Er@NaYbF 4 A method for preparing a core-shell structure, comprising the steps of:

[0044] (1) Prepare three kinds of solutions of 1, 2, and 3 respectively: weigh 0.4 mmol of rare earth oxide 1 (Ln 2 o 3 ), put the rare earth oxide 1 into a 50mL three-neck flask, add a small amount of deionized water (2-3mL) into it, heat up under magnetic stirring conditions, and set the temperature at 160°C. When the temperature rose to 80 °C, 1.5 mL of trifluoroacetic acid was added dropwise to the flask, and the solid was completely dissolved after a few minutes to obtain a transparent solution 1. Using the same method, 0.6mmol rare earth oxide 2 (Yb 2 o 3 ) and 1.5 mmol sodium hydroxide solid. Prepared as a clear solution 2. Weigh 0.5mmol of sodium hydroxide solid into a 25mL three-necked flask, add a small amount of deionized water, and dropwise add 0.5mL of trifluoroacetic acid thereinto, until the solid is completely dis...

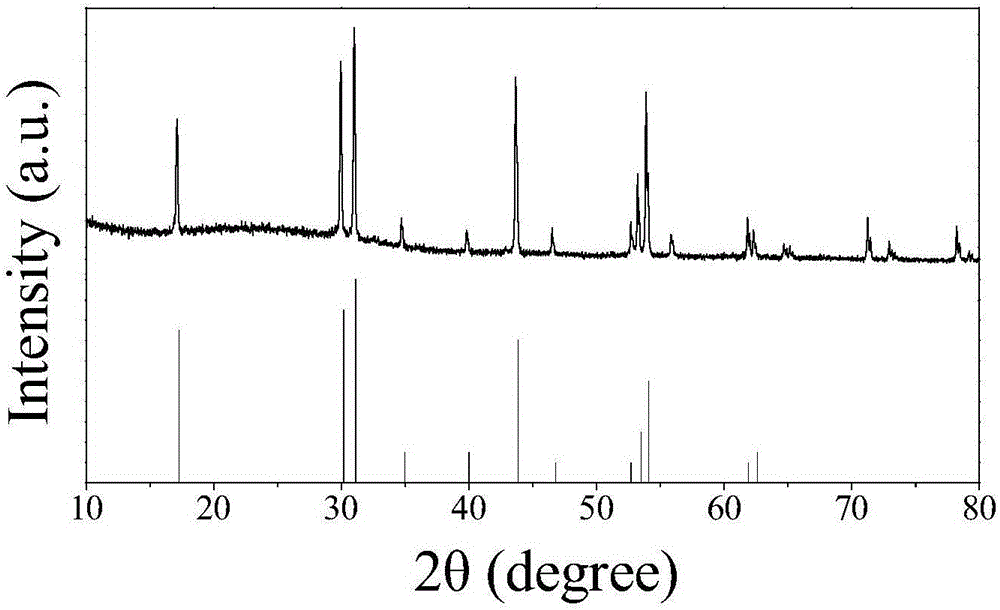

Embodiment 3

[0049] Upconversion fluorescent nanomaterial β-NaGdF 4 :20%Yb,2%Tm@NaGdF 4 A method for preparing a core-shell structure, comprising the steps of:

[0050] (1) prepare three kinds of solutions of 1, 2 and 3 respectively: take by weighing 0.4mmol rare earth oxide 1 (Ln 2 o 3 ), put the rare earth oxide 1 into a 50mL three-neck flask, add a small amount of deionized water (2-3mL) into it, heat up under magnetic stirring conditions, and set the temperature to 150°C. When the temperature rose to 80 °C, 1.5 mL of trifluoroacetic acid was added dropwise to the flask, and the solid was completely dissolved after a few minutes to obtain a transparent solution 1. Adopt the same method to weigh 0.6mmol rare earth oxide 2 (Gd 2 o 3 ) and 1.5mmol sodium hydroxide to prepare a transparent solution 2. Weigh 0.5mmol of sodium hydroxide solid into a 25mL three-necked flask, add a small amount of deionized water, and dropwise add 0.5mL of trifluoroacetic acid thereinto, until the solid i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com