Light container room made of foamed aluminum

A container and aluminum foam technology, which is applied in the direction of building types, special buildings, small buildings, etc., can solve the problems of strong thermal conductivity of steel plates, large cost ratio, short service life, etc., and achieve strong energy absorption and light weight ratio The effect of strength and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

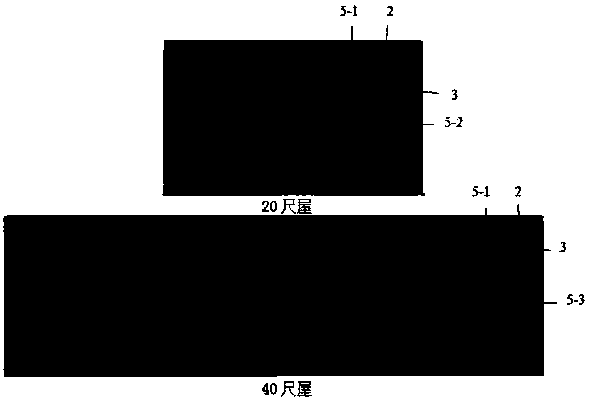

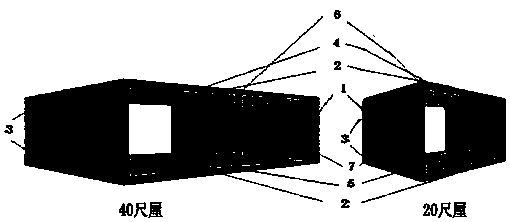

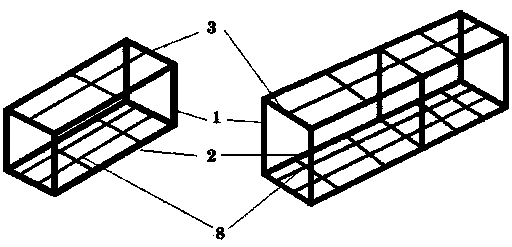

[0050] Figure 1-Figure 8 1 is the column, 2 is the top and bottom beam, 3 is the top and bottom side beam, 4 is the top panel, 5 is the bottom panel, 6 is the long side panel, 7 is the short side panel, 8 is the keel frame, 1-1 is The surface of the column, 1-2 is the sandwich layer inside the column, 1-3 is the tongue and groove of the column, 1-4 is the pull ring, 2-1 is the upper and lower panels of the beam, 2-2 is the sandwich layer between the panels, 2-3 3-1 is the upper and lower panels of the short beam, 3-2 is the sandwich layer between panels, 3-3 is the tongue and groove of the short beam, 4-1 is the 7.2kg foam aluminum alloy veneer / and Its single-sided composite veneer, 4-2 is a 20-foot roof top panel, 4-3 is a 40-foot roof top panel, 5-1 is a foamed aluminum alloy veneer weighing 14.4 kg / and its single-sided composite veneer 、5-2 is the bottom panel of 20 feet roof, 5-3 is the bottom panel of 40 feet roof, 6-1 is 7.5kg foam aluminum alloy veneer / and its single-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com