Energy saving biological sewage treating method of low soluble oxygen filament bacteria sludge expansion

A technology for biological sewage treatment and sludge bulking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

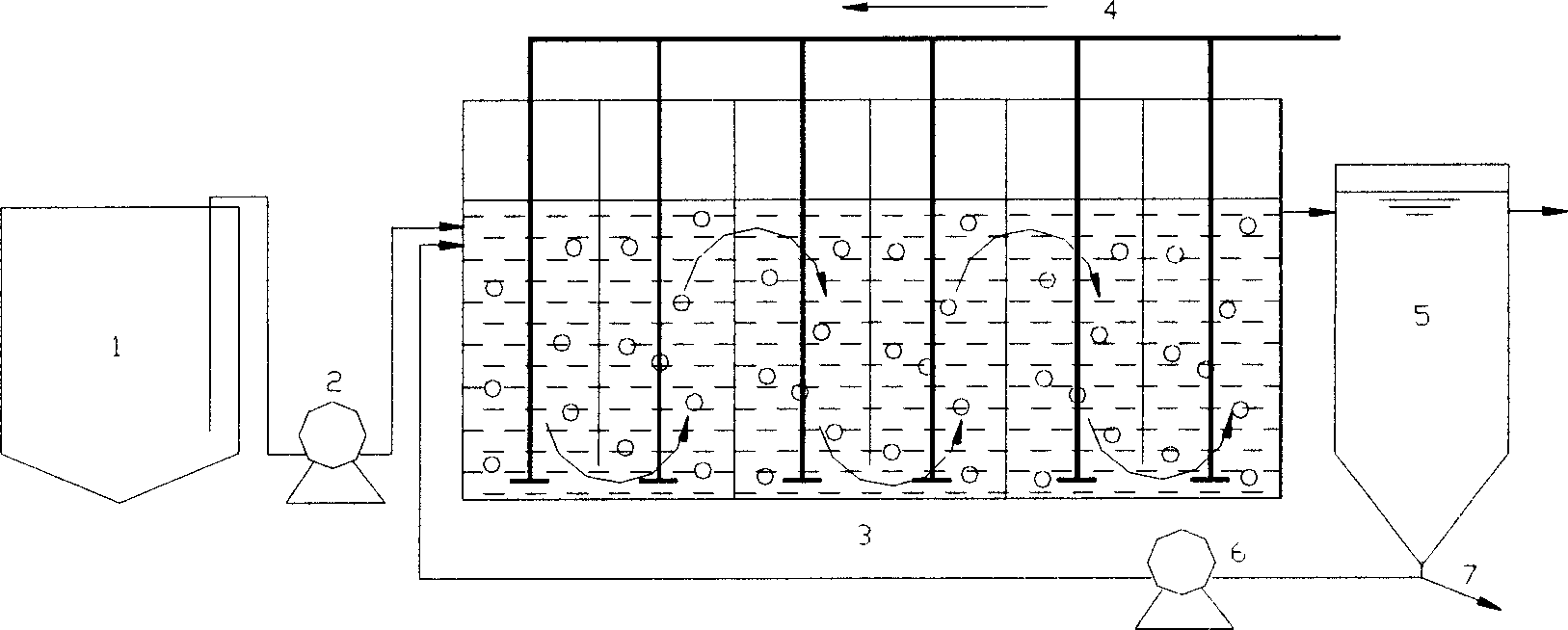

Method used

Image

Examples

Embodiment 1

[0043] The actual domestic sewage in a residential area is used as raw water (pH=7.2~7.8, COD=160~655mg / L). The selected improved A / O process reactor has an effective volume of 66L, the MLSS in the reaction tank is about 3000mg / L, and the reaction temperature is between 20 and 23°C. The sludge reflux ratio is 85-105%, and the residence time in the secondary settling tank is more than 2.5 hours. Reduce DO concentration from 2.0mg / L to 0.4-0.8mg / L. Filamentous bacteria sludge bulking occurs. The COD removal rate is basically not affected, and remains at about 90%. The removal rate of SS is improved, and SS cannot be detected in the effluent. TN removal rate increased from 30-45% to 55-75%. It can save 15-18% of the aeration oxygen supply.

Embodiment 2

[0045] An urban sewage treatment plant in Beijing adopts the oxidation ditch process, and currently treats 170,000 m3 of water 3 / d. Its main process parameters: sludge age of 16 days; reflux ratio of 100-120%; sludge concentration of 4000-6000mg / L; oxidation ditch hydraulic retention time of about 16.8 hours. The design residence time of the secondary sedimentation tank of the sewage treatment plant is 3.4h, the actual operating water volume has not reached the design water volume so far, and the actual residence time of the secondary sedimentation tank is about 4.0h. The aeration rate will be low, and when DO is reduced to 0.3-0.8 mg / L, filamentous bacteria sludge bulking will occur. The quality of the treated effluent remains good. COD, BOD 5 , SS and ammonia nitrogen removal rates are still maintained above 90%.

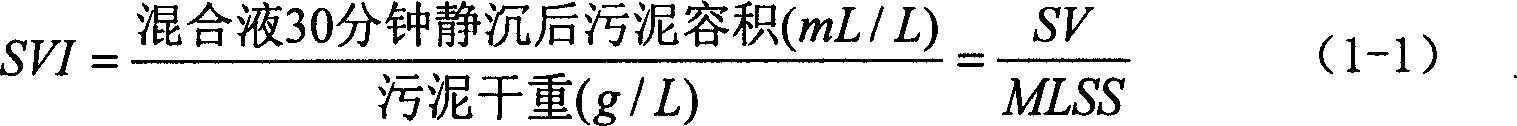

Embodiment 3

[0047] An urban sewage treatment plant in Chongqing adopts the improved oxidation ditch (A / O process) process, and the current treated water volume is 7000m 3 / d. The sludge age is 10-15 days; the sludge concentration is about 5000mg / L; the total nominal residence time of the oxidation ditch is about 21.2 hours; the reflux ratio is about 100%. The design stop time of the secondary sedimentation tank is 5.2 hours, and the actual stop time is about 7.5 hours. After adopting low dissolved oxygen operation, the dissolved oxygen concentration in the oxidation ditch is reduced from the original 2.0 mg / L to below 1.0 mg / L, mostly between 0.5 and 0.8 mg / L. SVI rose from 70mL / g to above 110mL / g. The daily power consumption of the aeration equipment is reduced by about 20% compared with the original one. The effluent COD, BOD, and TP concentrations remained at the original level. The removal rate of TN is significantly improved, and the concentration of TN in the effluent is reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com